Light Steel Corner V Shape L Bead Wall Angle Profile Roll Forming Machine

Wall angle machine can produce different type or size light steel keel frame, speed is fast, it can up to 35m per minute.The machine also could punch hole, press or inject logo on the finished product. Work speed is fast and easy operation by PLC control, only one person can operate it.We can customize machine follow with your requirement.

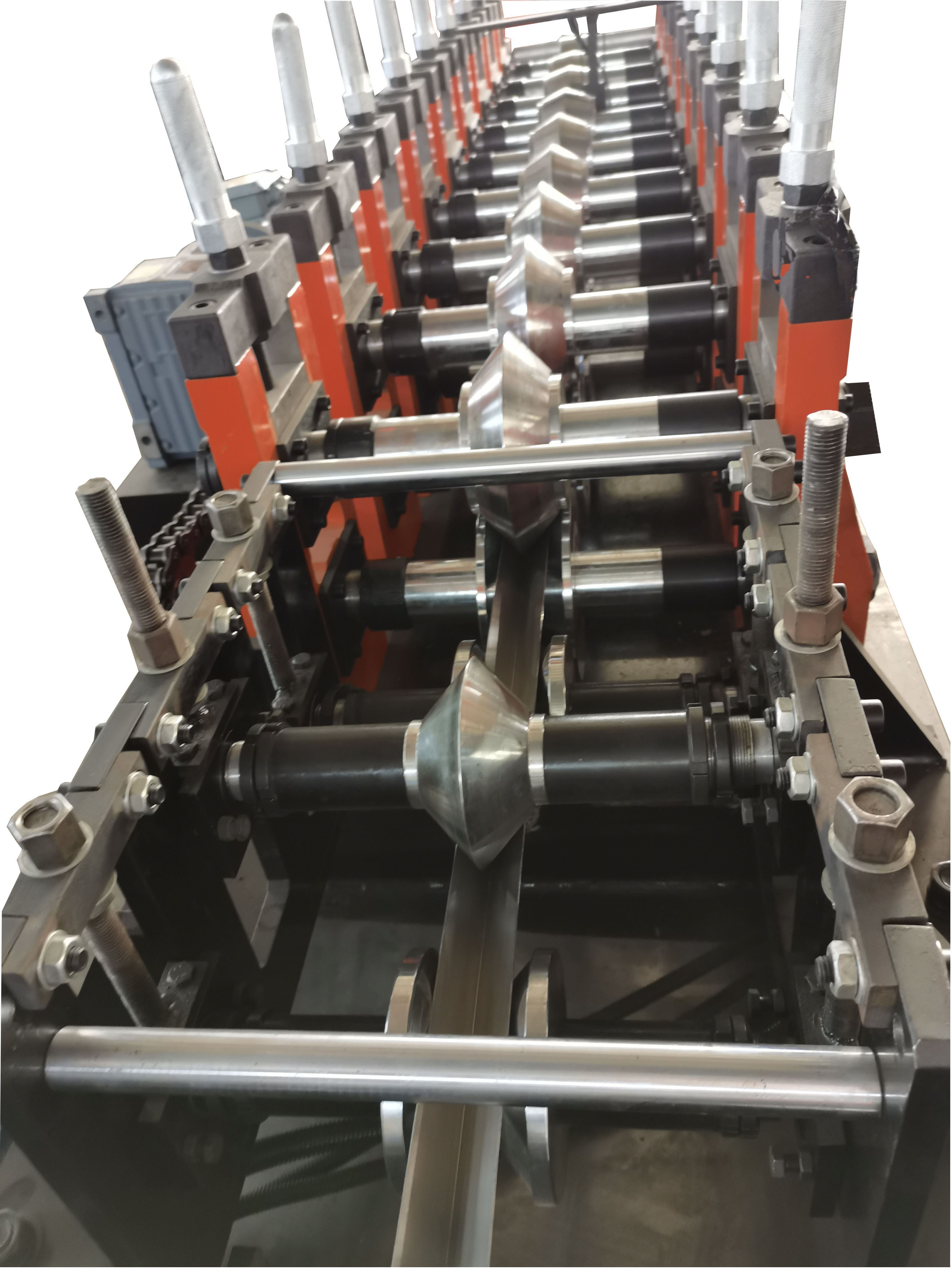

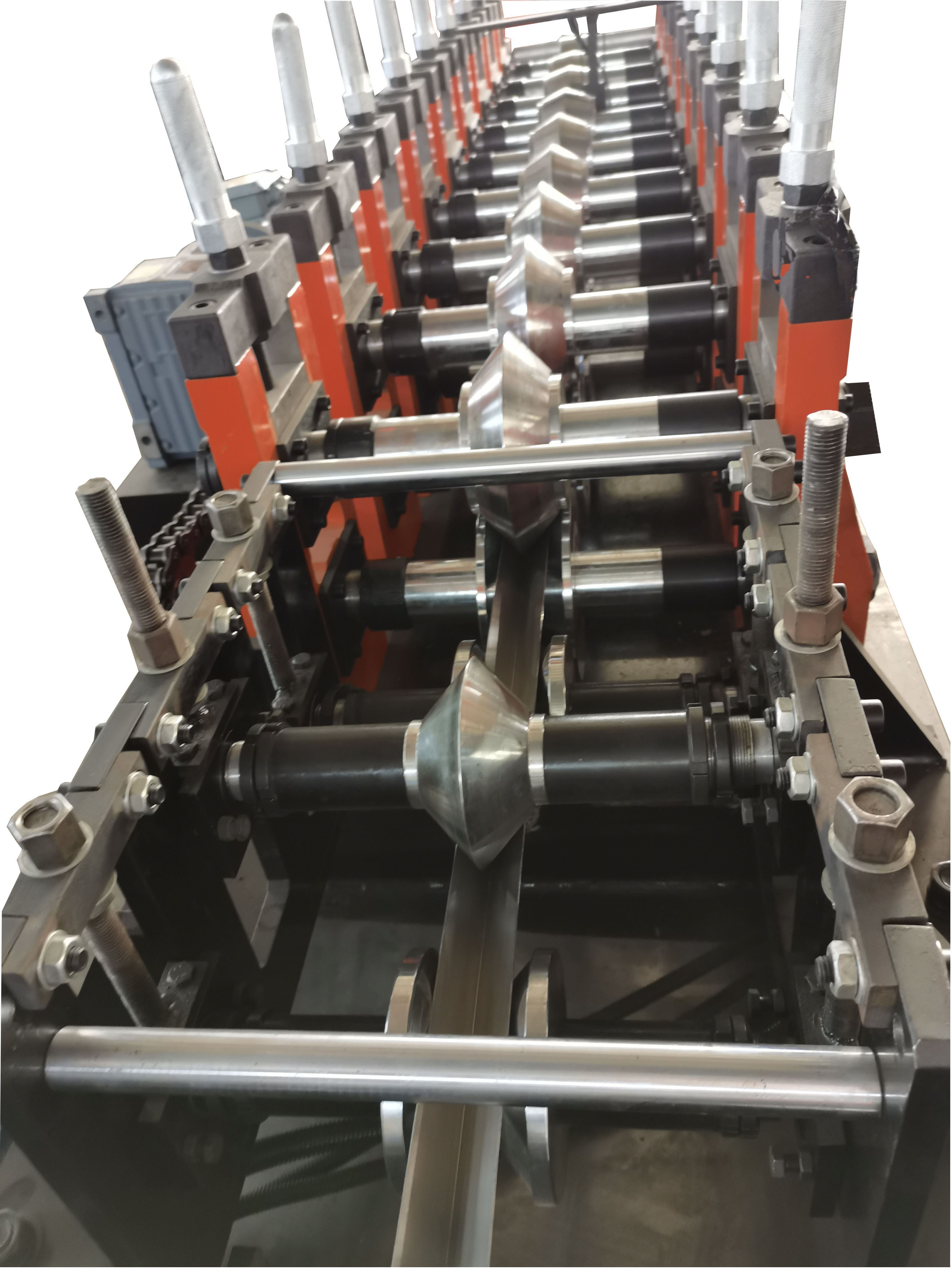

Detail Photos Of Wall Angle Profile Roll Forming Machine:

Cutting driven by servo motor,so it is non-stop working, then machine is running in high speed:

Specification

| Items | Wall Angle Roll Forming Machine |

| Total power | 4kw(3 phase,50 hz /60ha,380v/220v/230v/440v |

| Speed | 0-35m/min |

| Dimension(L*W*H) | 5.5m*1.2m*1.6m |

| Weight | 3.0 tons |

| Roller station | 10 pairs |

| Frame | Cast frame+tube/steel box |

| Material thickness | 0.4-0.8mm |

| Material width | Follow with design |

| Transmission system | Chain |

| Cutting system | Hydraulic cylinder(profile cutting system) Material SKD11 Japan |

| Control system | PLC,Xinjie |

| Runout table | Manual 3m,100kg load |

| Decoiler | Manual / Electrical,1.5 tons |

| Equipment |

| PLC | XINJIE(China) |

| Touch panel | XINJIE(China) |

| Electric motor | BOJIANG(China) |

| Encoder,relay | OMRON(Japan) |

| Hydraulic components | GUOWEI(China) |

| Cutting blades | SKD11(Japan) |

| Rollers | Cr12/GCr15 |

Advantage Of L Bead Roll Forming Machine:

High-Efficiency Productivity

Roll forming shapes lighter-weight metal components faster than many other production processes and at higher volumes. The process requires minimal human intervention because computer-aided design (CAD) software can manage the structural composition and design pattern. Roll forming machinery can also incorporate additional in-line services like welding and punching to streamline operations. Requiring nominal finishing and producing little material waste make for a highly efficient process overall.

Reliable Accuracy

As an incremental method, roll forming bends components in consecutive stages, allowing for high levels of accuracy and control as well as tight tolerances. Also, CAD software can guide the metal forming process from end to end for a consistent and quality end product.

Versatility

Roll forming can perform profile bending for sheets of ferrous or nonferrous metals with different thickness levels. There is flexibility in part design as components can consist of a single bend or an intricate pattern of geometric shapes, all with a high degree of precision and uniformity. The process is ideal for producing U-channels, C-channels, round and closed shapes as well.

Part Dimension Capabilities

The roll forming process and its machinery reduce the need for seams by allowing you to shape longer metal components, and in varying lengths, all with one tool set. Stud and track machinery, for instance, can generate framing as long as is required. Brake pressing and stamping operations cannot accommodate the lengths of material that roll forming equipment can.

Cost-Efficiency

Roll forming reduces material waste thanks to increased precision in the end product. As the parts are of good quality with reliable consistency, you’ll have fewer cut-offs, seams, or rejected parts. The cost per unit drops as the production volume increases, and roll forming companies can pass these savings on to the customer.