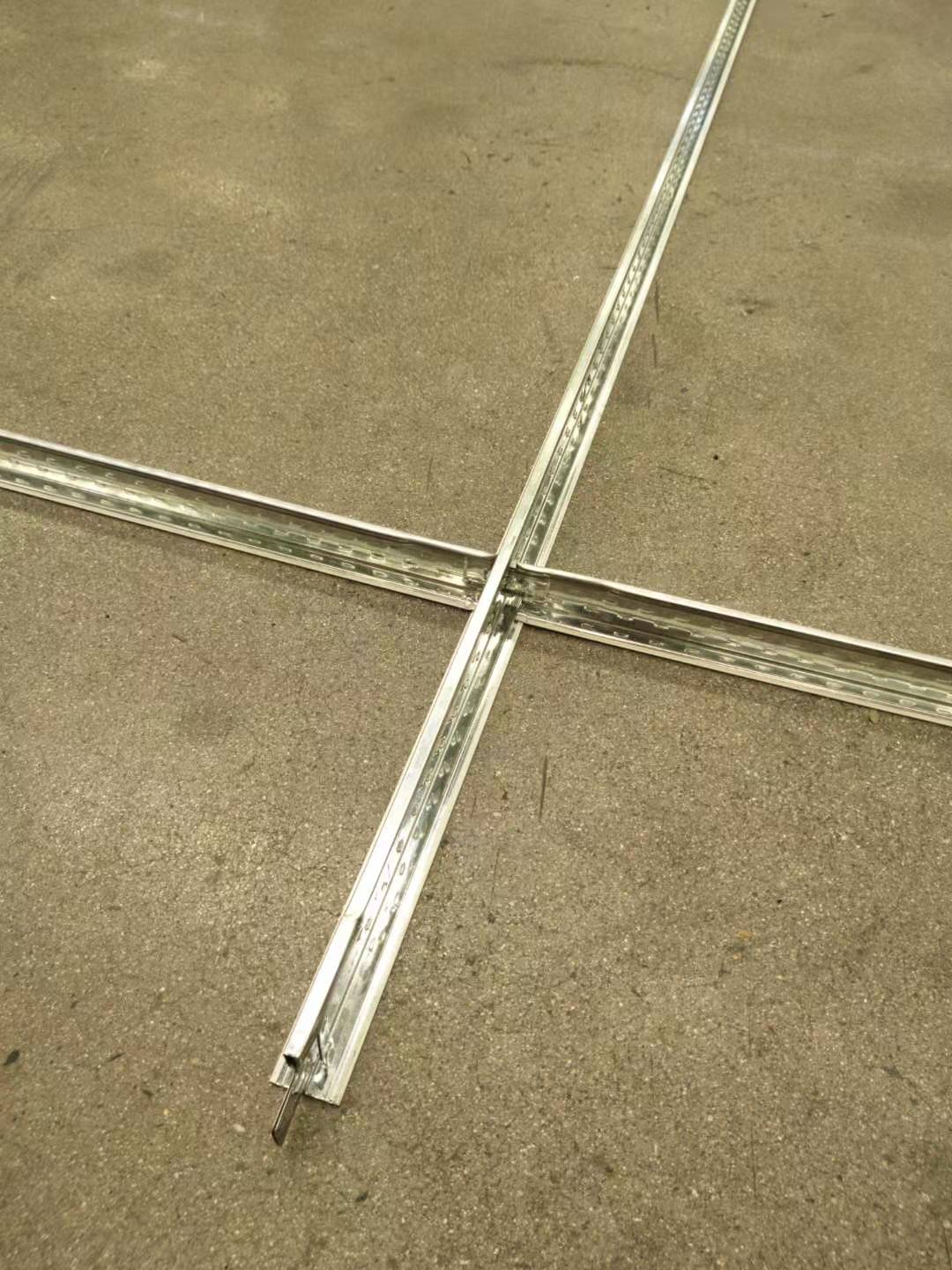

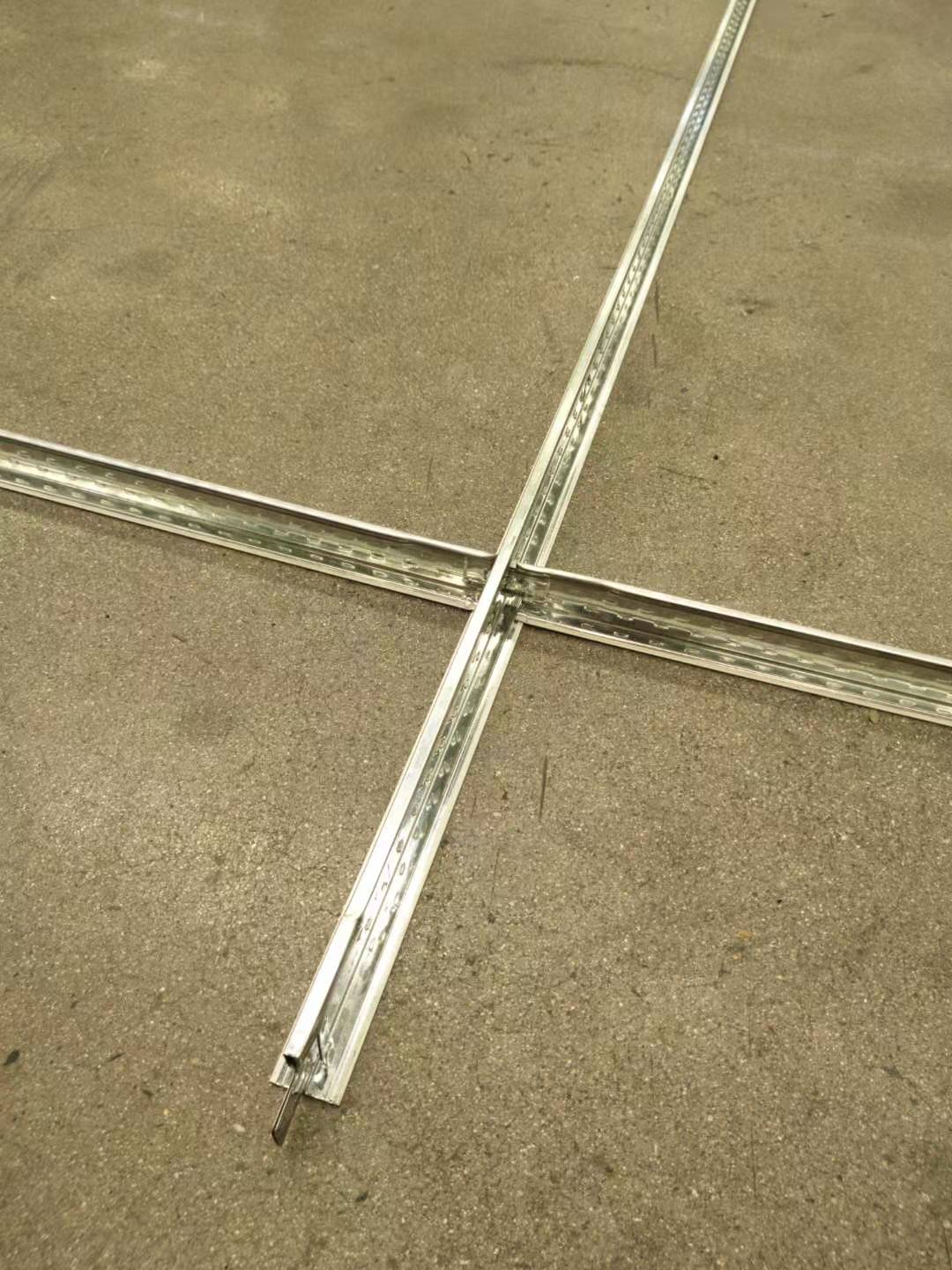

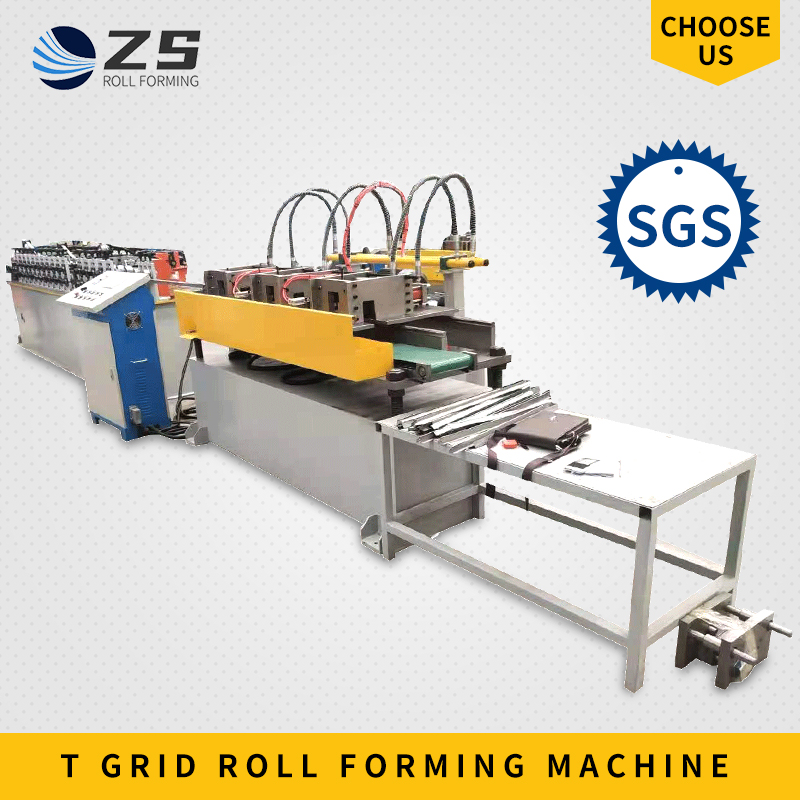

Punching And Cutting Office Roof Gypsum Ceiling Shilloutte T Grid Making Roll Forming Machine

The suspended ceiling t grid roll forming machine is a cost effective, high product volume, and flexible production line. The sizes and designs are different in different market. We offer fully automatic t grid roll forming machine.

Length:3600mm/1200mm/600mm

Size:24*38mm,24*32mm

Thickness:0.25-0.4mm

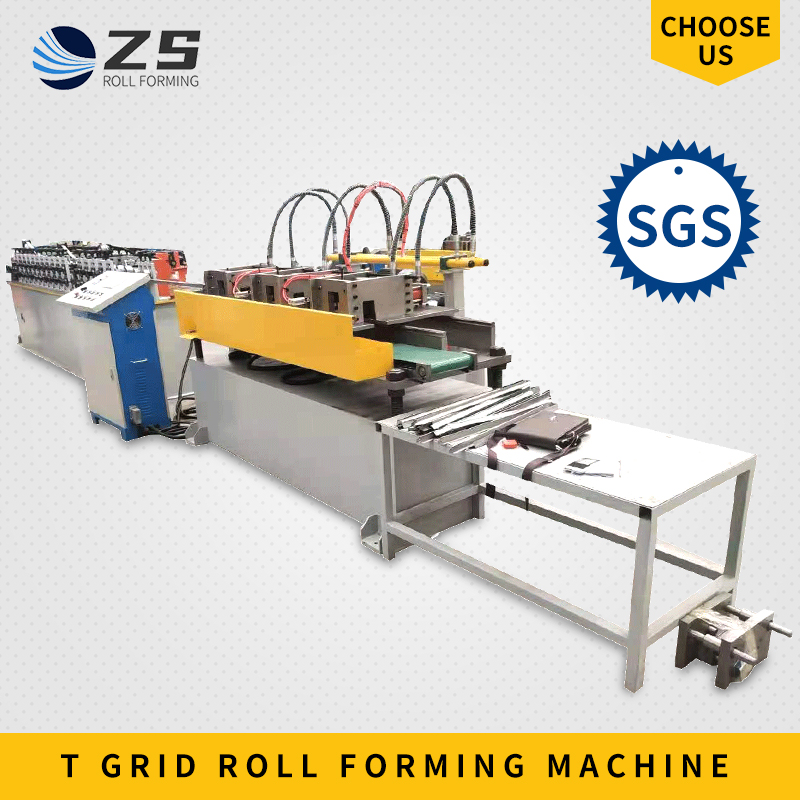

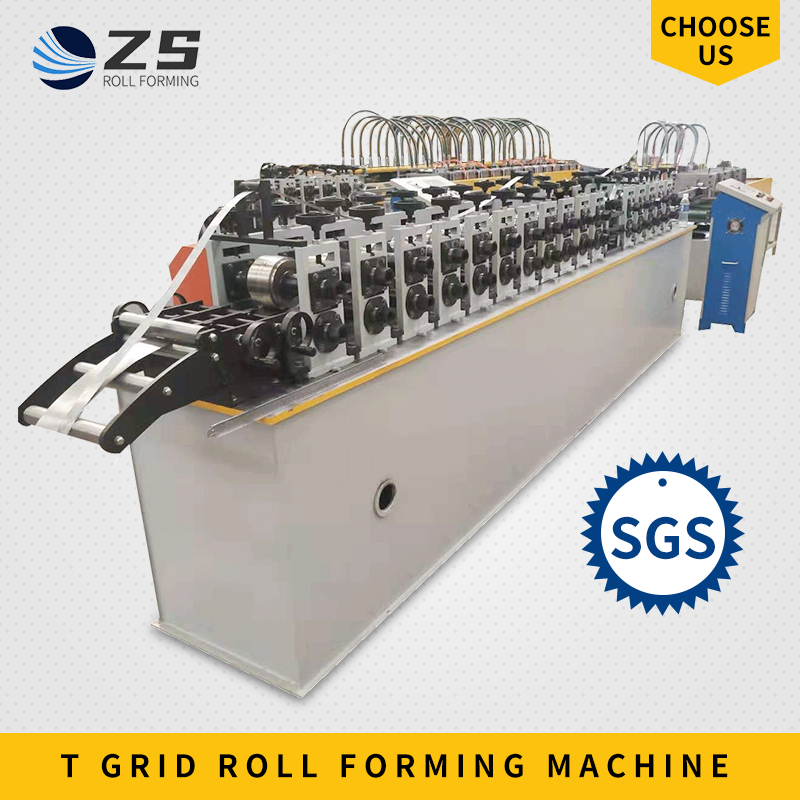

Components of T Grid Roll Forming Machine,it is full complete line,save labors,only need one worker to operating this machine:

Roll Forming Machine | 1 Set |

Dies Of Punching Hole | 1 Set |

Hydraulic Station | 1 Set |

PLC | 1 Set |

Servo Motor Following Cutting | 1 Set |

Decoiler | 2 Sets |

TECHNICAL DETAILS Of T Grid Roll Forming Machine:

1. Decoiler

Capacity:2 Tons Max width:≤700mm Inner Range:φ480-520mm

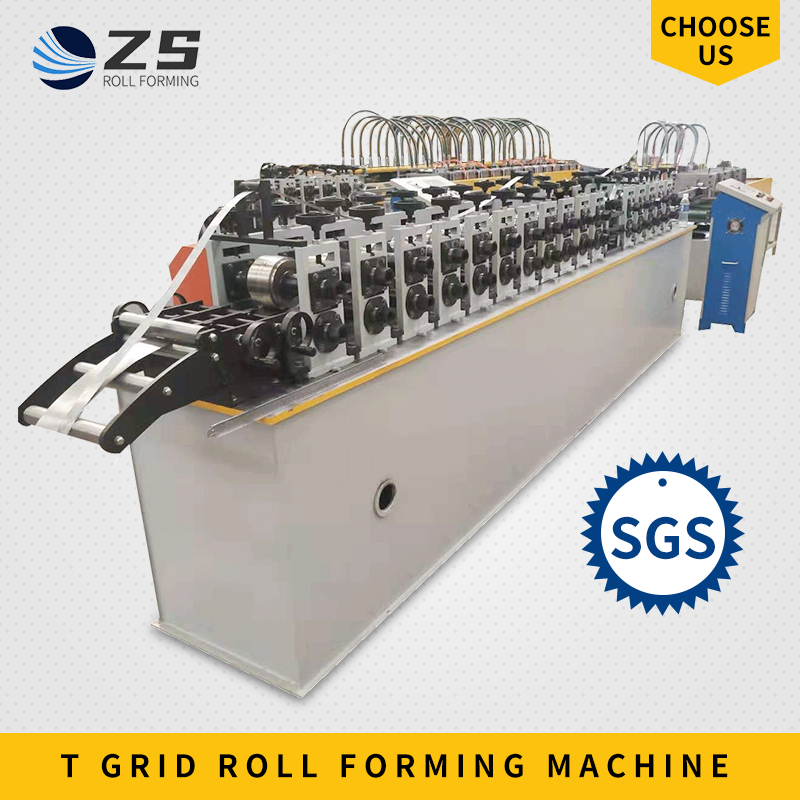

2. Roll Forming Machine of Gypsum Ceiling T Grid

Material Of Roller:Cr12,with hard treatment.

Stations Of Roller:18

Diameter Of Shaft:40mm

Material of Shaft:#45 steel,with hard treatment.

Power:5.5kw

Working Speed:0-30m/min

Dimension:26m*3m

3. Servo Motor Driven Cutting And Punching

Driven:Hydraulic oil pump and servo motor

Power of Servo Motor:10kw

Power of Hydraulic Station:15kw

Material Of Blade:SKD11,with hard treatment,HRC58-62°

Advantages Of Full Automatic Punching And Cutting Office Roof Gypsum Ceiling Shilloutte T Grid Profile 3600mm Making Roll Forming Machine:

1.This complete production line is controlled by PLC,touch screen.Operator set up the task through the set program and monitor the control process.So it is very easy to operating this line.

2.Machine is produce T Grid in high speed to meet the large requirement of Market.