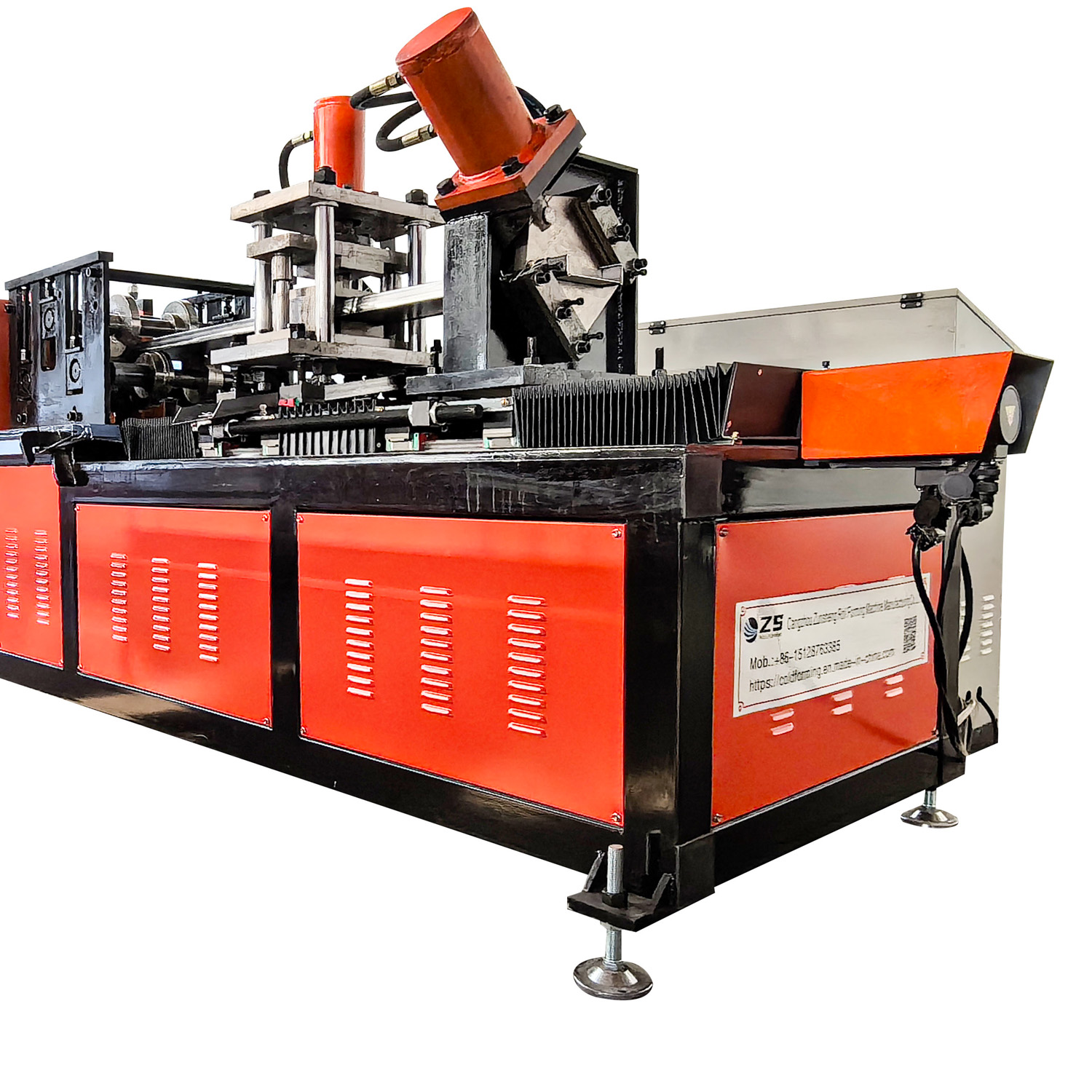

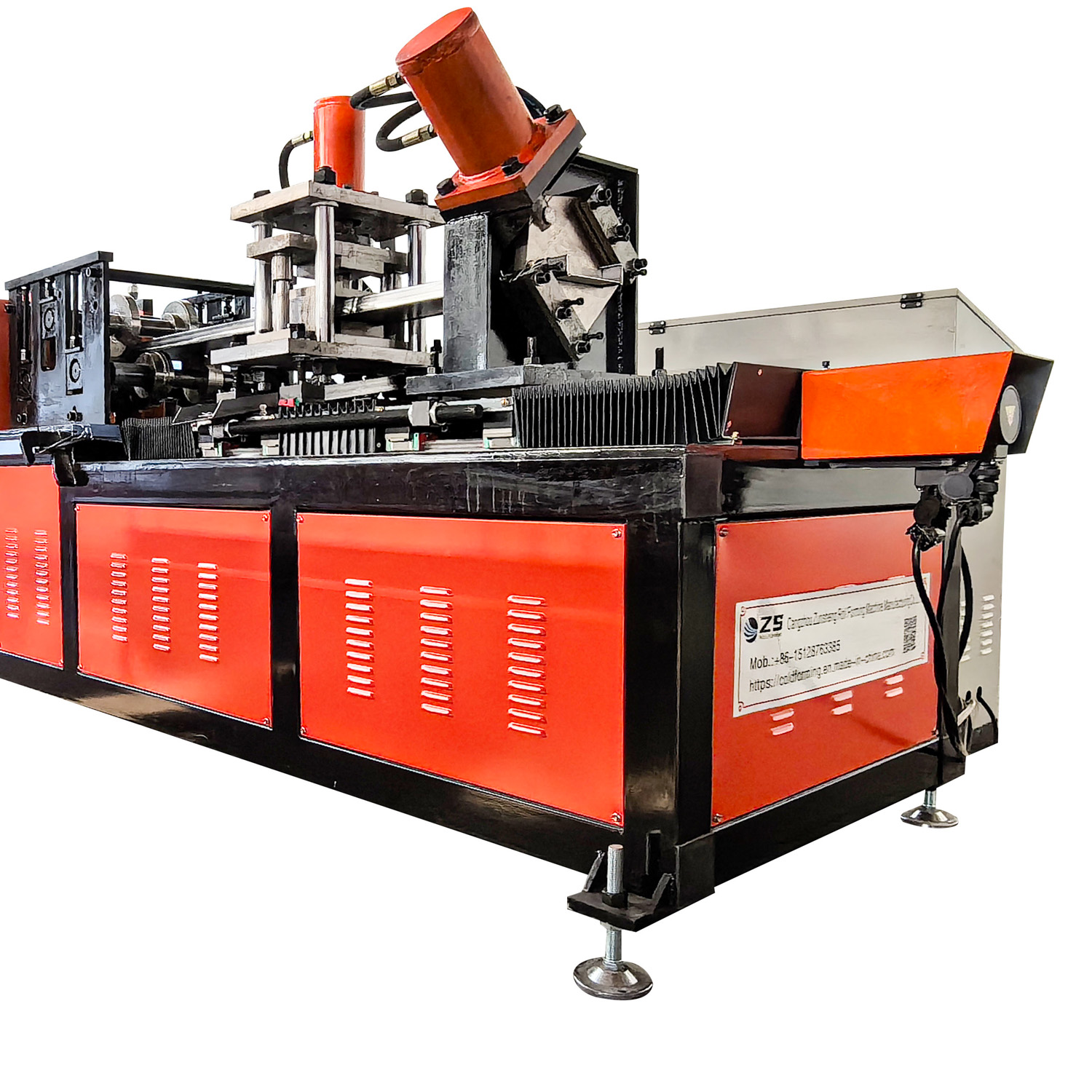

Automatic Adjustment Drywall Steel Frame Stud And Track Roll Forming Machine

Reliance stud and track roll forming machine is an automatically adjustable roll forming system that can produce the most commonly used stud and track sizes in one machine. It’s high volume and quality solutions for stud and track production. It’s also named metal stud machine, metal stud forming machine, stud roll forming machine, metal stud roll forming machine, steel stud roll forming machine, drywall stud roll forming machine, c stud roll forming machine, metal stud roll former, etc.

Motor and hydraulic system use inner sytle, so it is have nice look.

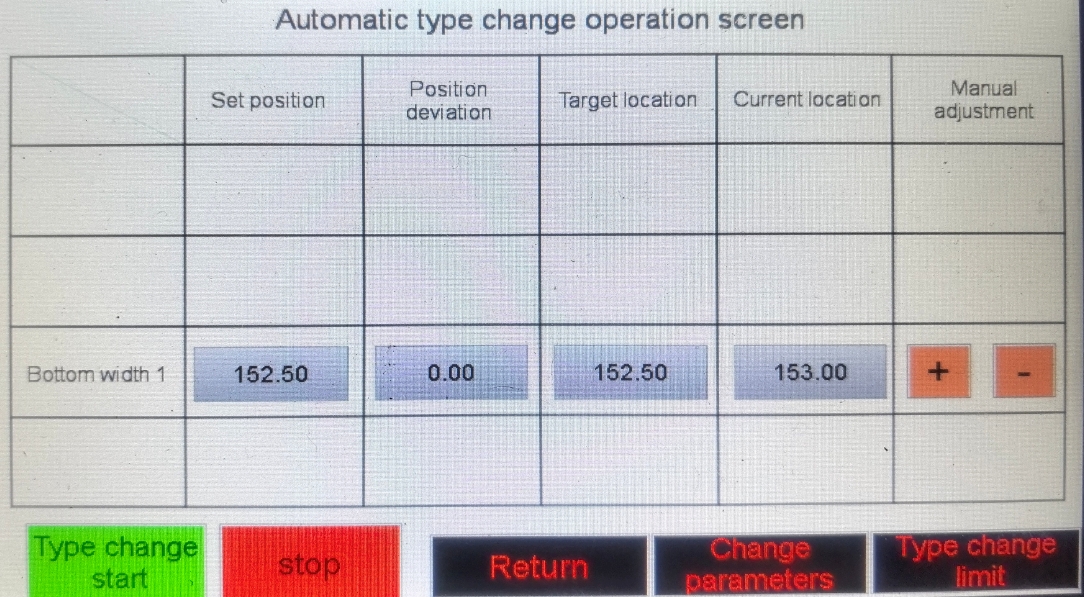

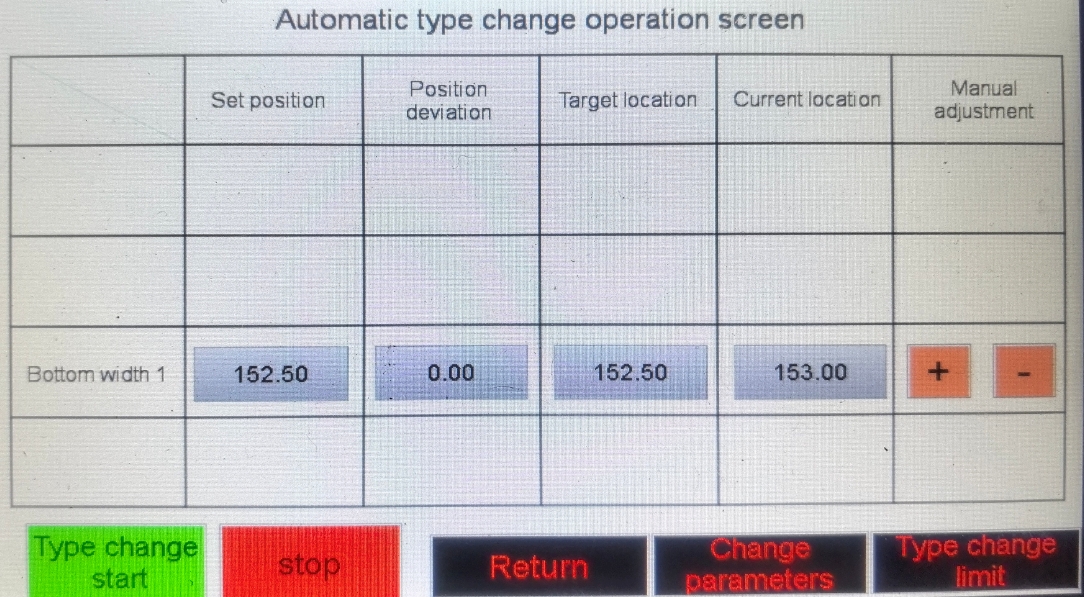

Adjusting size by PLC, it is very fast and high precision,no need worker manual adjust again.

Punching hole and cutting driven by servo motor, they are non-stop working, then it is can improve working speed to meet our customer's high production.

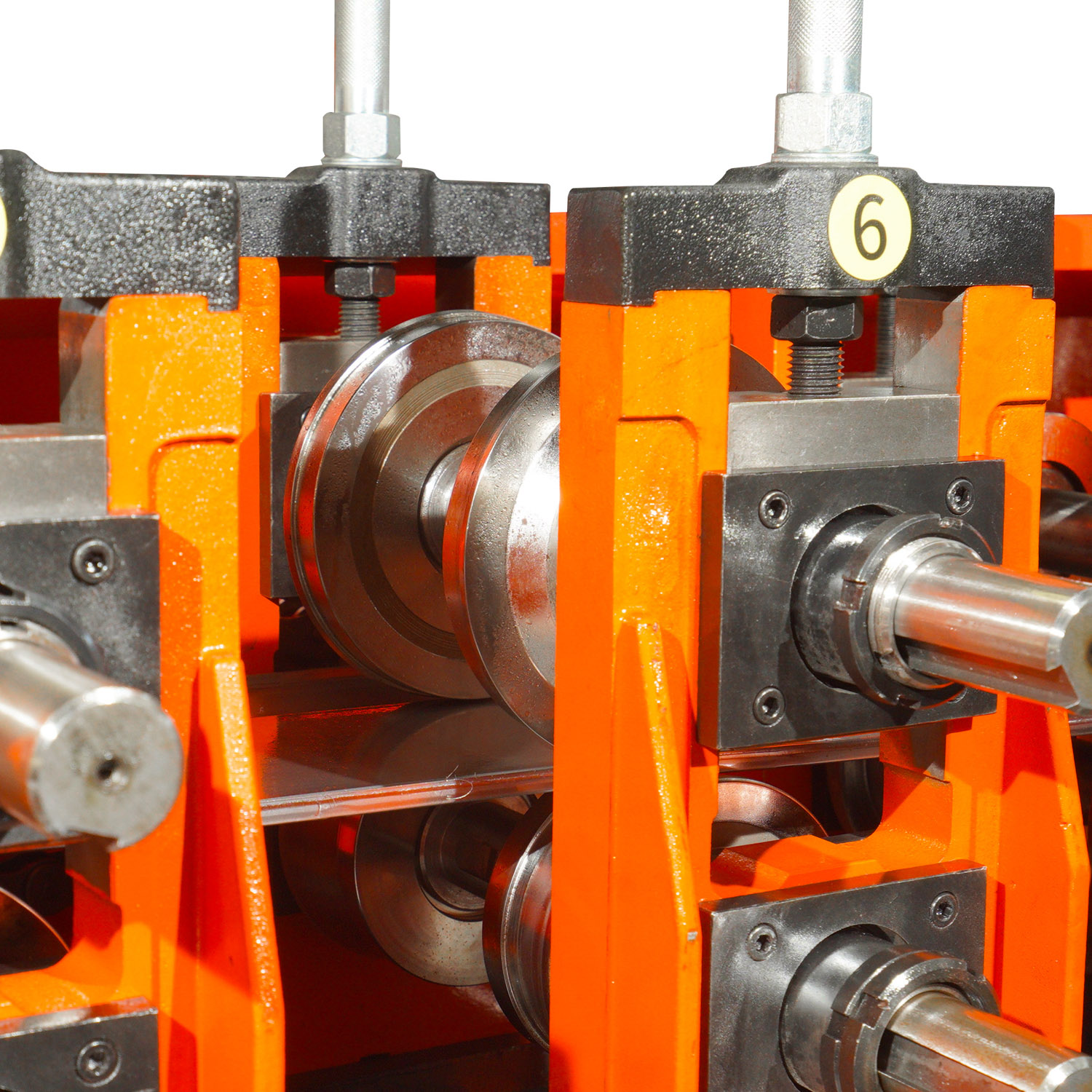

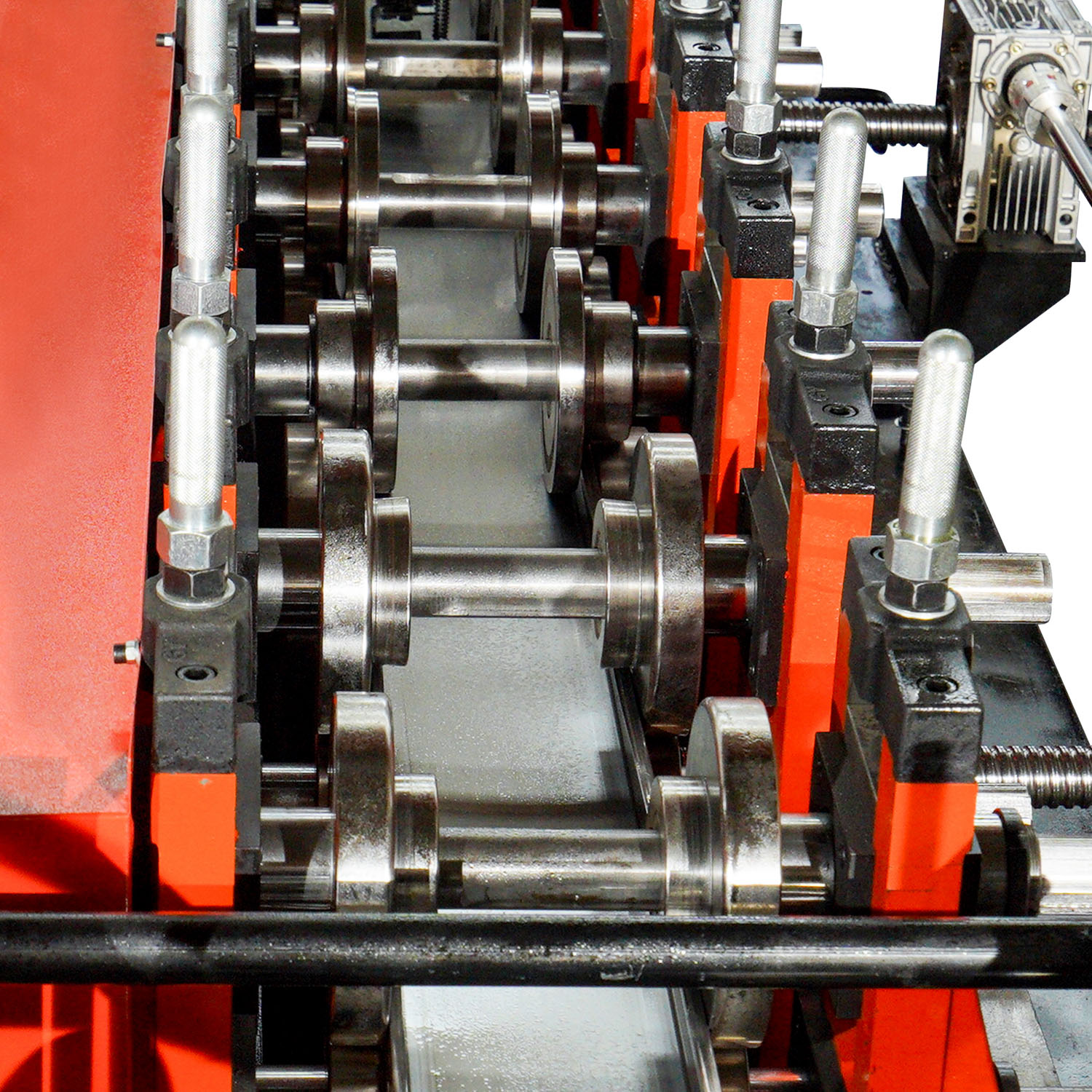

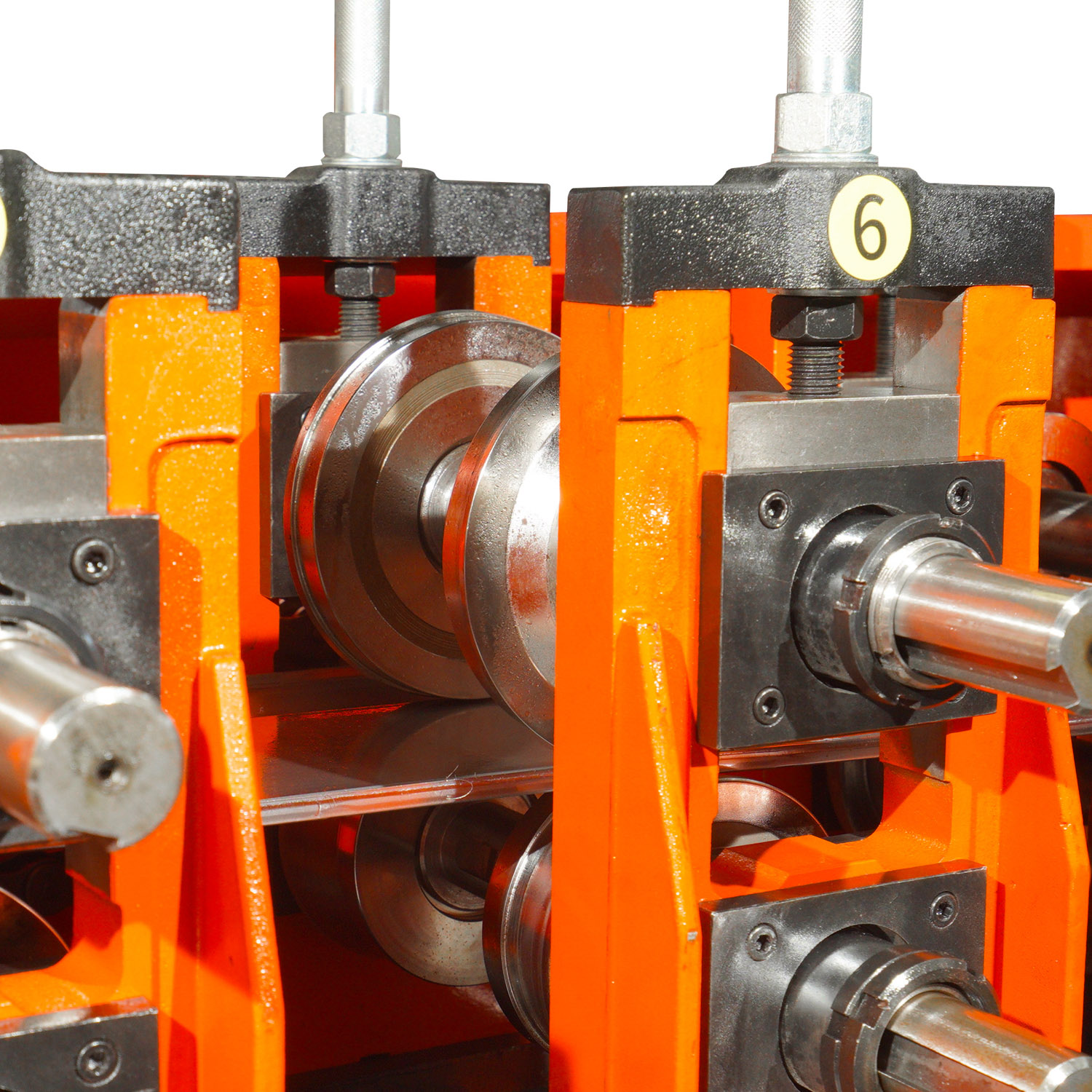

All stations use casting frame, it is without cutting and welding, so will be in high precision forming profiles. And we mark numbers for all stations to make they are clear when we help customer to solve after sell service.

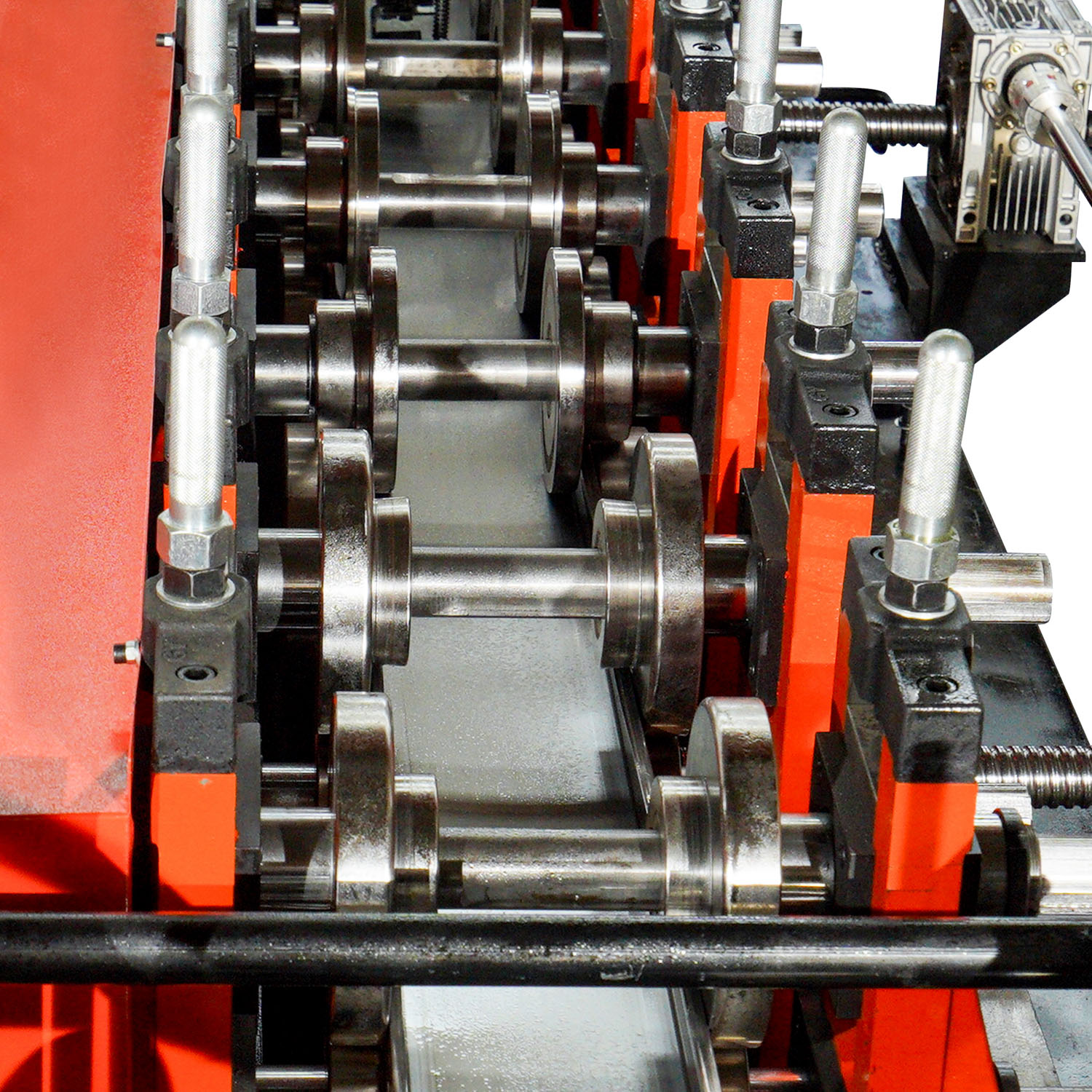

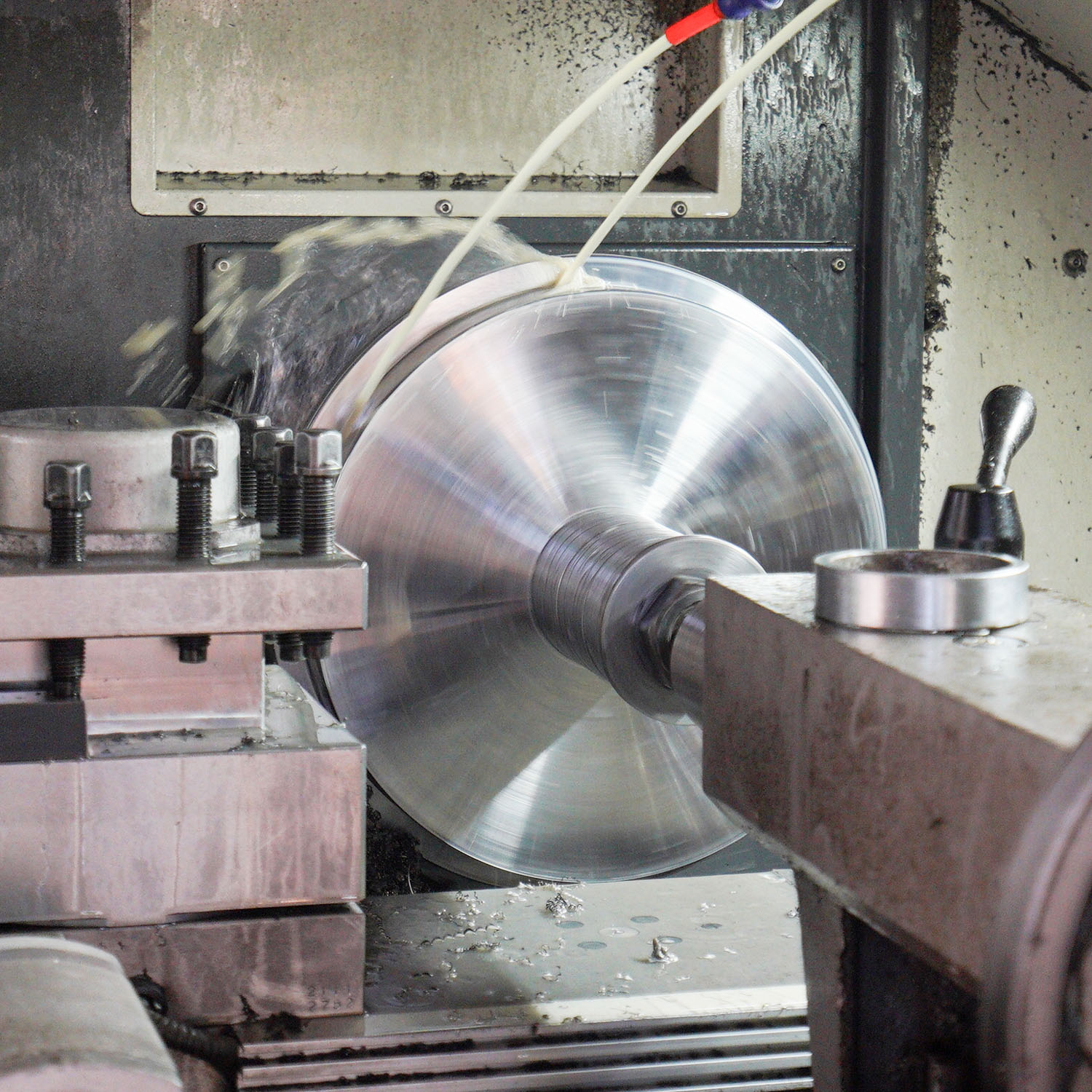

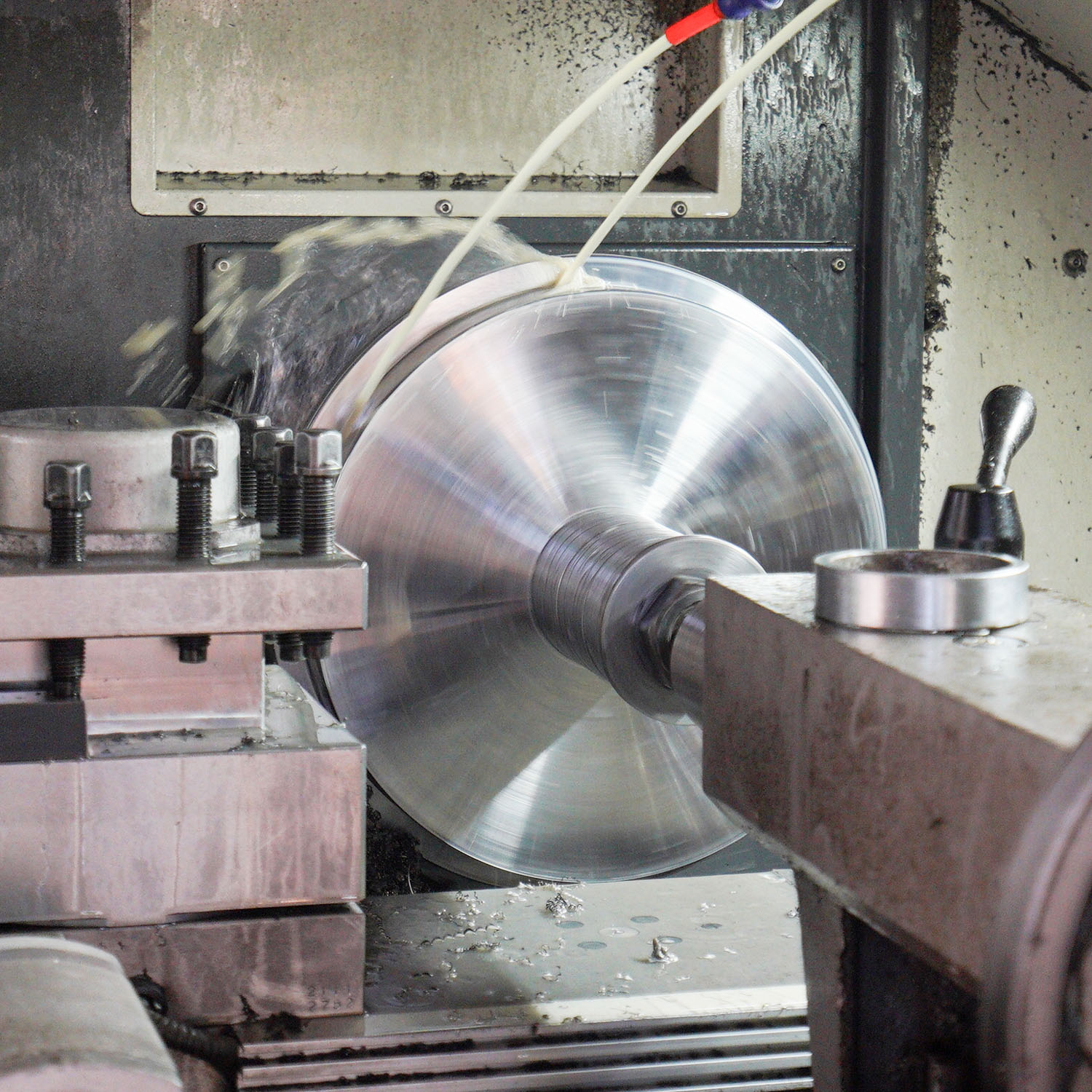

All rollers designed by rich experience engineer and processed by CNC Milling Machine.

We can match printer and packing machine with roll forming machine if you need it.

Specification:

No. | Item | Unit |

|

| High Speed Stud And Runner Roll Forming Machine |

1. | Material Of Processing |

| Galvanized Steel |

2. | Feed coil Thickness | mm | 1.2-1.5 |

3. | Y.S | M pa | 300 - 650 |

4. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

5. | Shaft Diameter | mm | 60 |

6. | Roll Station | No. | 12 |

7. | Rolling material |

| GCr15 |

8. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

9. | Line Speed | m/min | 25-30 |

10. | Drive Type of Roll Forming Machine |

| Chain |

11. | Power of Main Motor | kw | 7.5+2.3 |

Cutting Machine |

12. | Type |

| PLC controlled Hydraulic Cutting |

13. | Thickness capacity | mm | 1.2-1.5 |

14. | Width capacity | mm | As drawing |

15. | Cutting blade steel grade |

| Cr12, quenching |

16. | Hardness |

| 58-62 HRC |

17. | Cutting tolerance | mm | +/- 1 |

18. | Cutting blade number | Pieces | 2 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Xinjie |

21. | Hydraulic system power | kw | 5.5 |

22. | Dimension Of Machine |

| About 5.5m*0.8m*1.4m |

23. | Weight | kgs | 3500 |

24. | Working area | m | 12-3 |

25. | Voltage |

| 220V,60HZ,3Phase |

Assemble Cost:Round trip air tickets,room and board, visa cost,commission 150USD/Day.

Lead Time:30 Working days after we received advance payment.

Payment Term:30 % Advance payment by T/T,balance 70% payment after test and before delivery.

Warranty:18 Months,spare parts breakdown,please send us the old parts,we will send new parts to you for free.