Servo Motor Gypsum Ceiling Profile Hat Channel Steel Furring Frame Roll Forming Machine

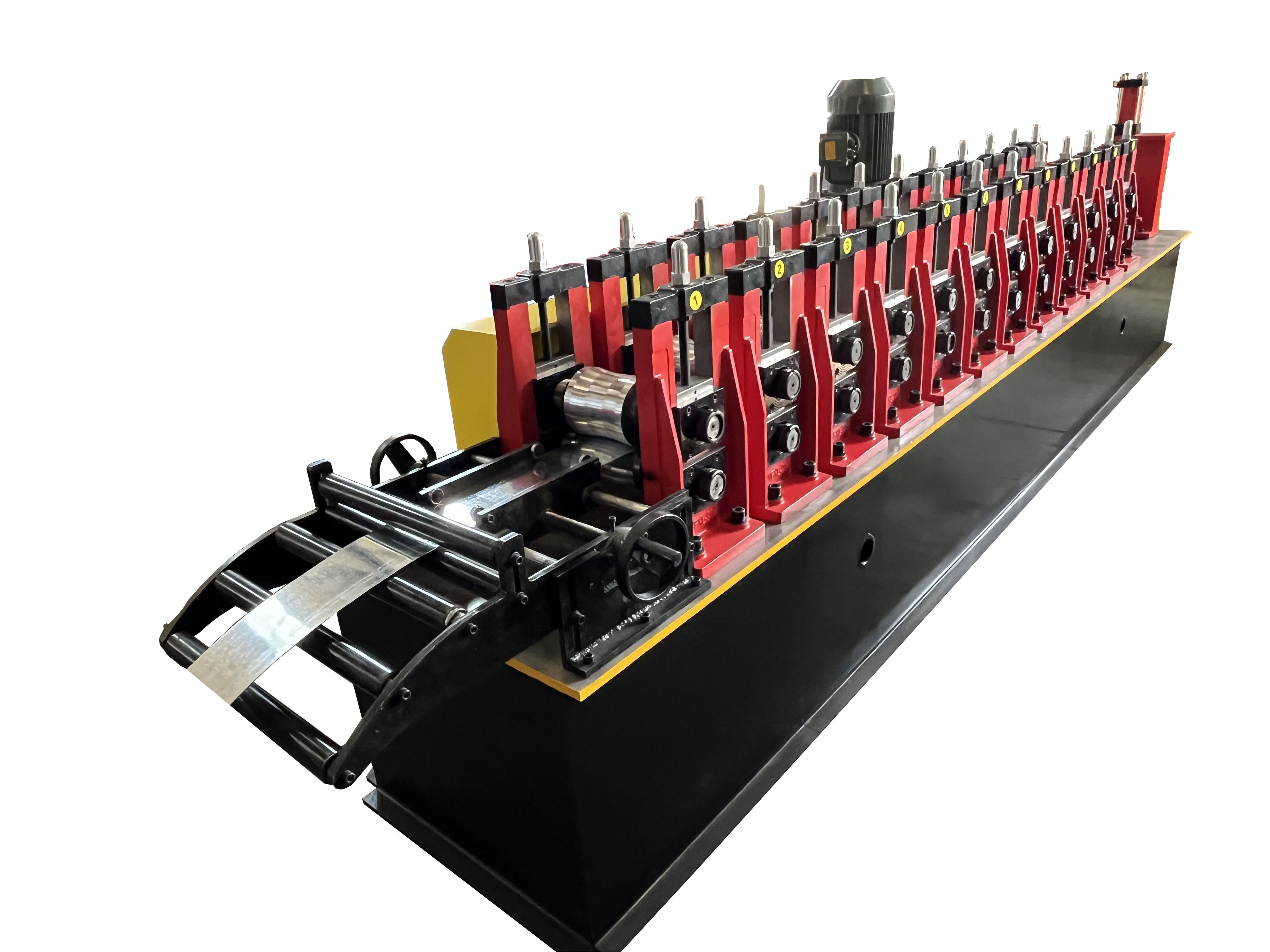

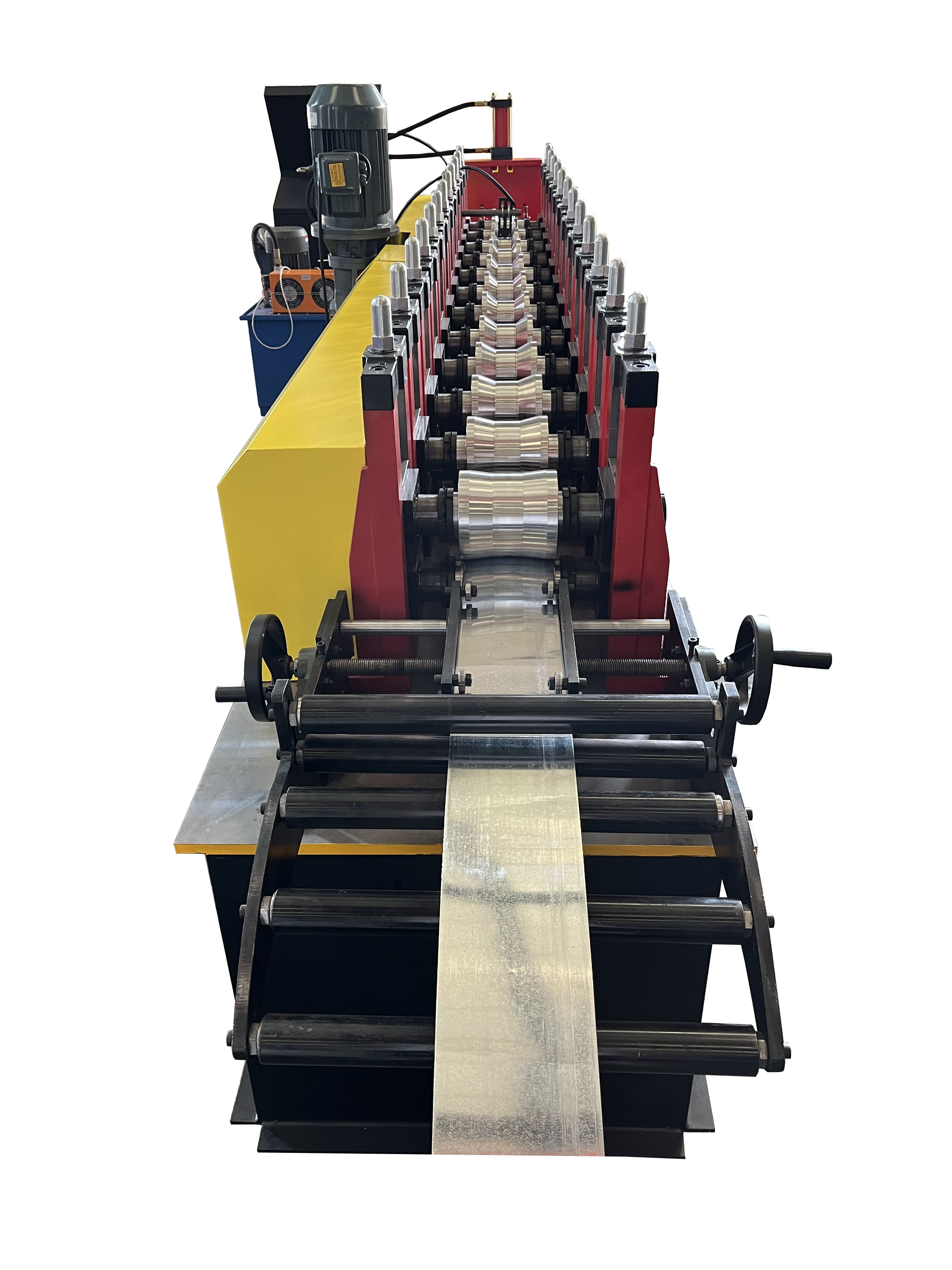

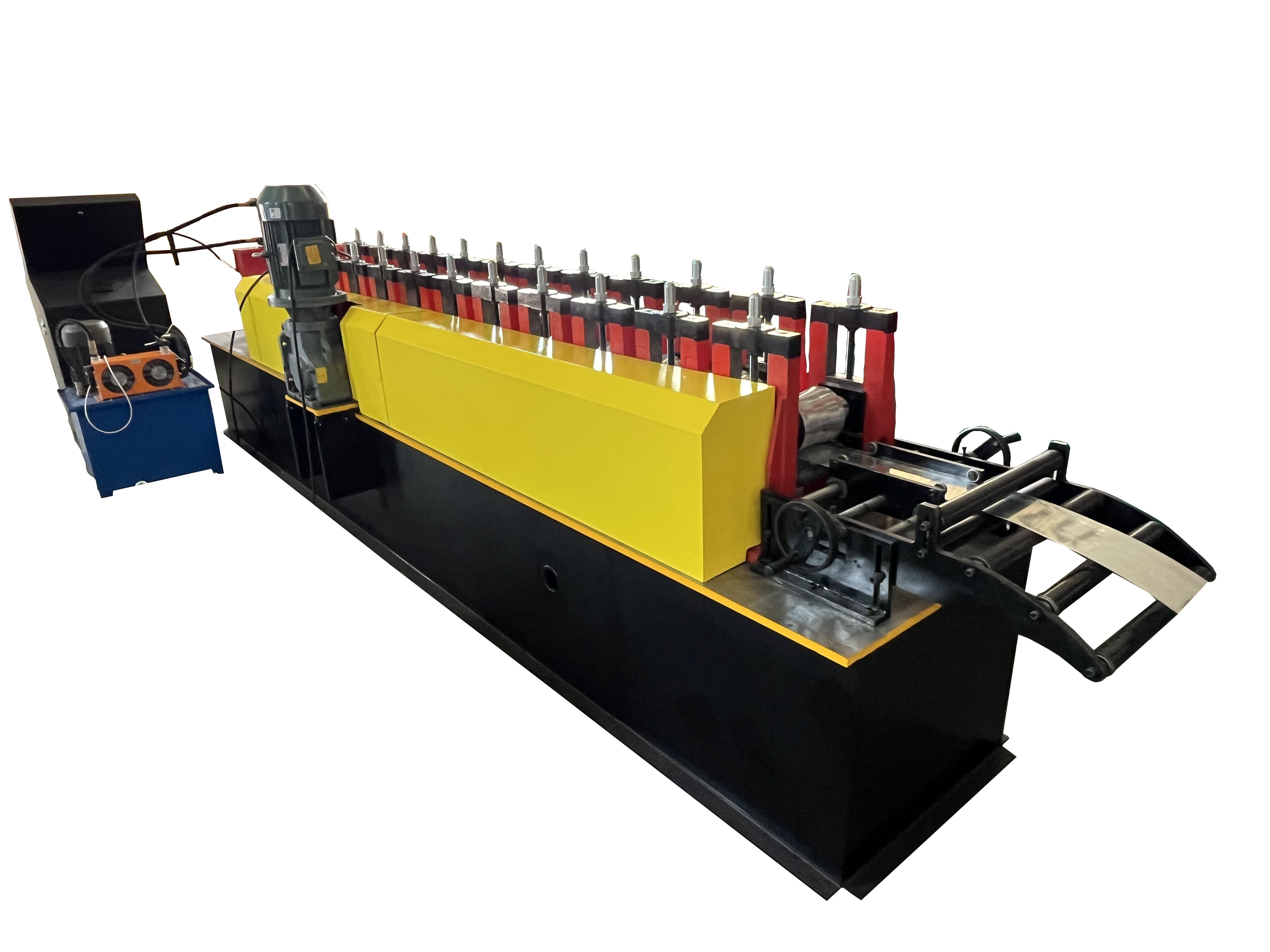

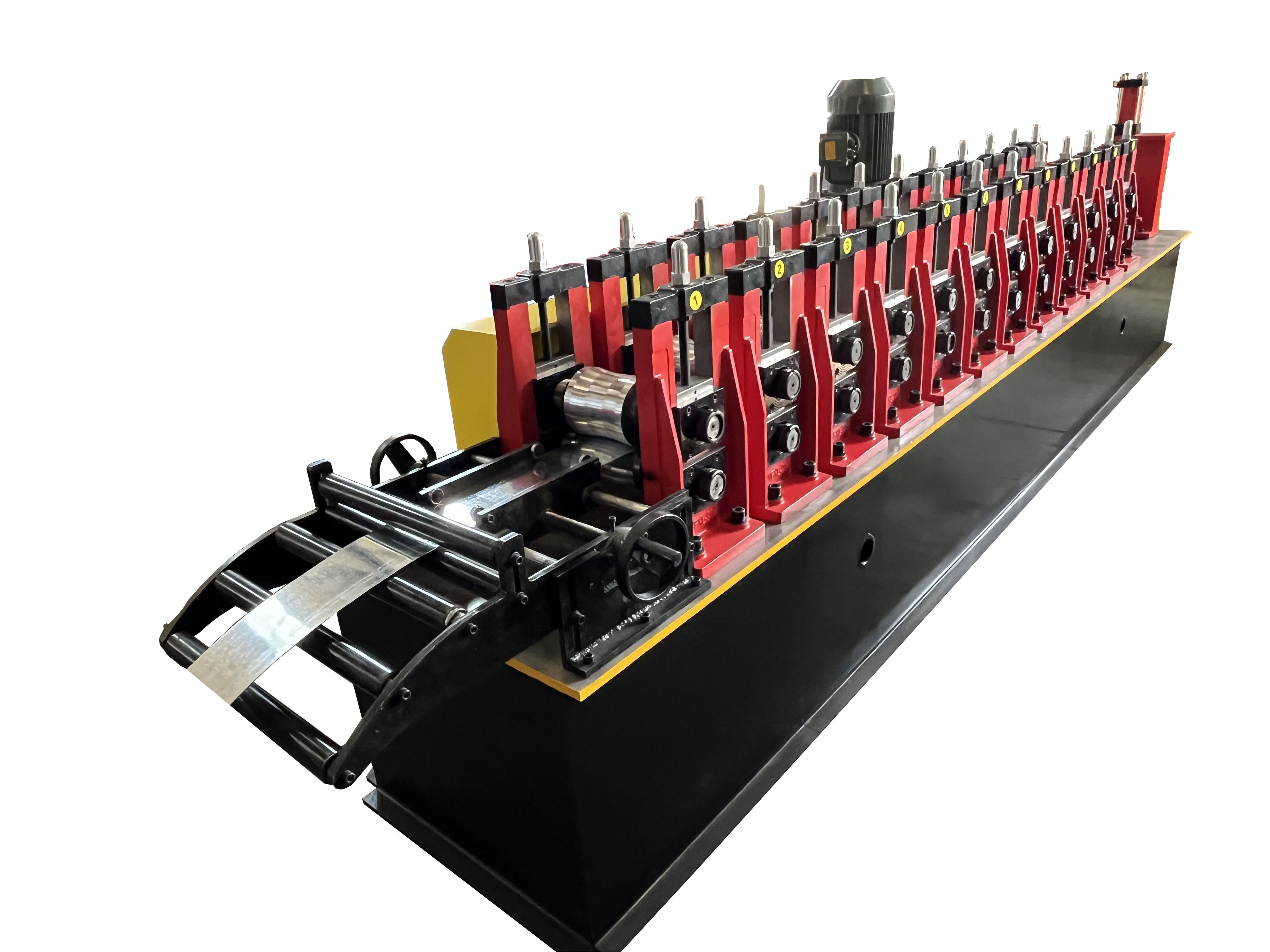

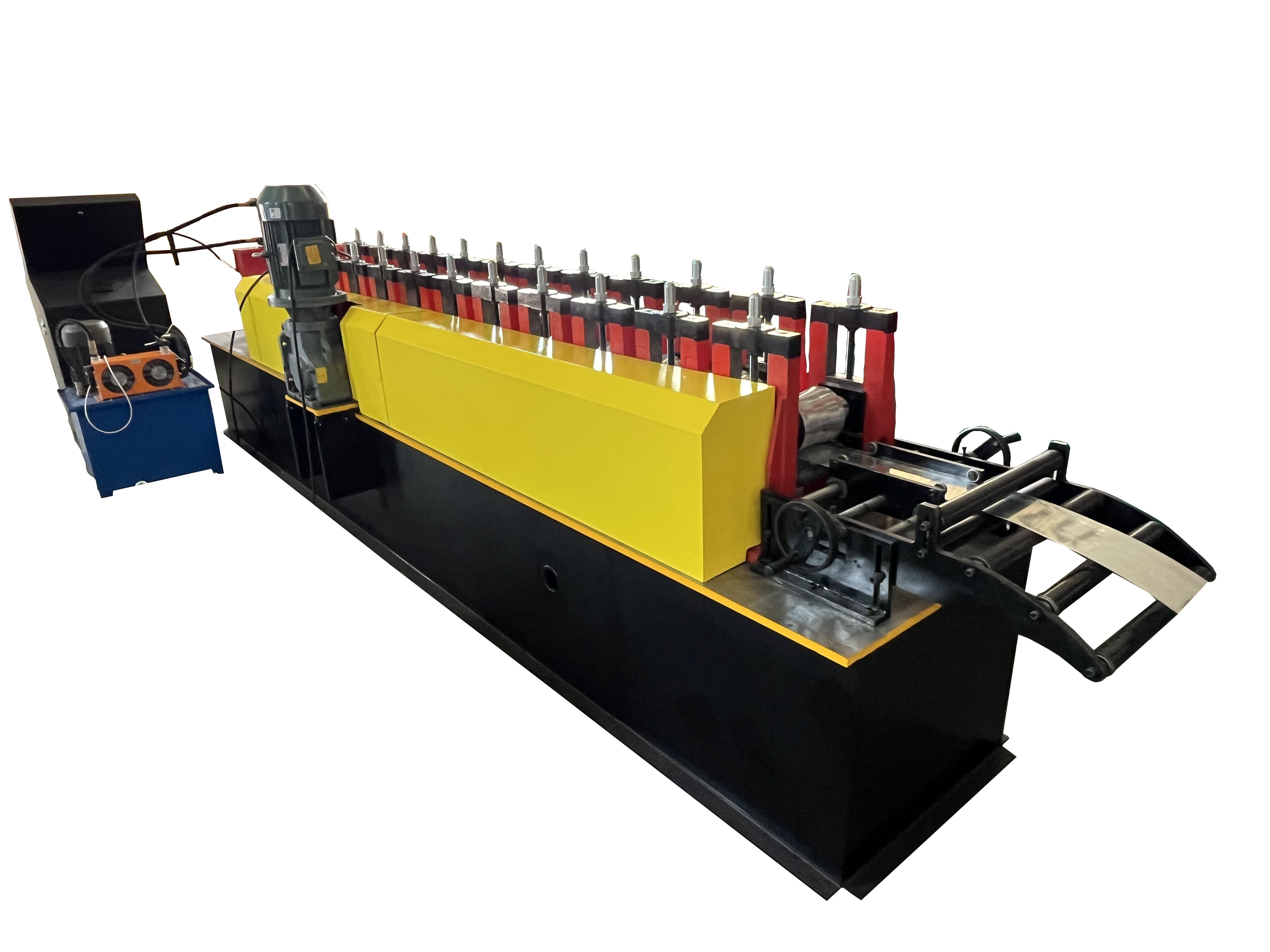

Hot Selling Good Price High Speed Servo Motor Gypsum Ceiling Profile Hat Channel Steel Furring Frame Roll Forming Machine.This machine is customize for Mexico customer, it is working for 1.0-1.5mm material. This machine is include decoiler,roll forming machine,PLC,hydraulic system and run out table.

Hot Selling Good Price High Speed Servo Motor Gypsum Ceiling Profile Hat Channel Steel Furring Frame Roll Forming Machine, photo detail for your reference.

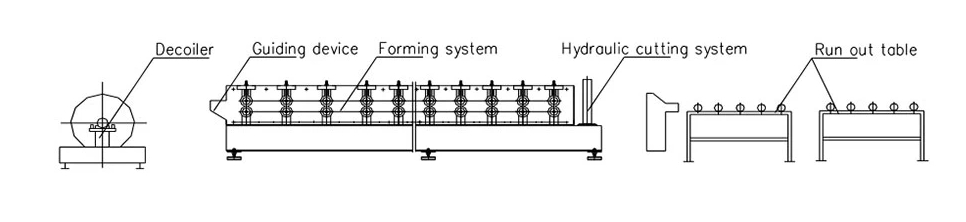

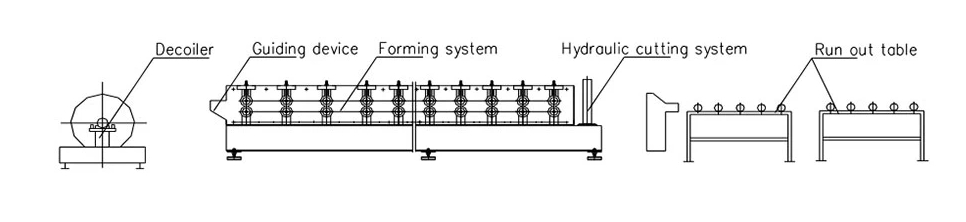

Gypsum Ceiling Profile Hat Channel Steel Furring Frame Roll Forming Machine Working Flow:

Electrical decoiler---Feeder---Roll forming machine---Hydraulic cutting system---Run out table

We use K-Series motor for this machine, it is running more stable and low noise. The latest design for feeder, it is can fix coil very well and it is not easy to swing when it is going to roll forming machine.

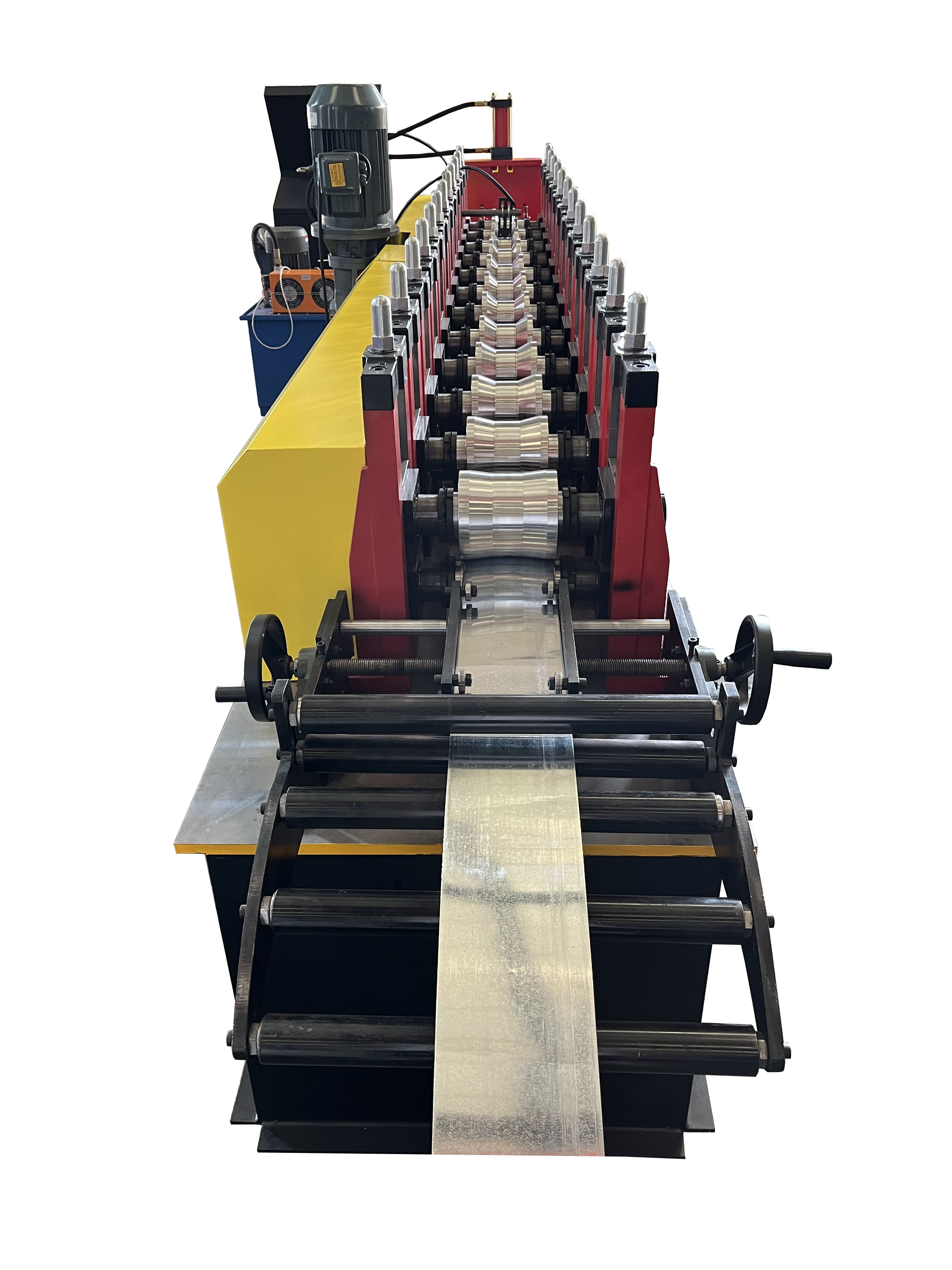

After all the rollers and shafts are finished by CNC lathes, they are hardened and tempered, then CNC lathes are finished again, and then they are precision processed with grinders, and finally they are chrome plated.Rollers and shafts processed by these processes can be more precisely roll former gauge steel.

We assembly nice cover for chain, it is safe for our workers when they are operating this machine.

Specification Of Hat Channel Roll Forming Machine:

No. | Item | Unit |

|

| Hat Channel Roll Forming Machine |

1. | Material Of Processing |

| Galvanized Steel |

2. | Feed coil Thickness | mm | 1.0-1.5 |

3. | Y.S | M pa | 300 - 650 |

4. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

5. | Shaft Diameter | mm | 70 |

6. | Roll Station | No. | 12 |

7. | Rolling material |

| Cr12 |

8. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

9. | Line Speed | m/min | 15-20 |

10. | Drive Type of Roll Forming Machine |

| Chain |

11. | Power of Main Motor | kw | 7.5 |

Cutting Machine |

12. | Type |

| PLC controlled Hydraulic Cutting |

13. | Thickness capacity | mm | 1.0-1.5 |

14. | Width capacity | mm | As drawing |

15. | Cutting blade steel grade |

| Cr12, quenching |

16. | Hardness |

| 58-62 HRC |

17. | Cutting tolerance | mm | +/- 1 |

18. | Cutting blade number | Pieces | 1 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Delta |

21. | Hydraulic system power | kw | 5.5 |

22. | Dimension Of Machine |

| About 5.5m*0.8m*1.4m |

23. | Weight | kgs | 3200 |

24. | Working area | m | 12-3 |

25. | Voltage |

| 230V,60HZ,3Phase |

Advantages of Gypsum Ceiling Profile Hat Channel Steel Furring Frame Roll Forming Machine:

1.We have new CNC milling machines and rich experience workers to process rollers for our machine, it is can sure all rollers in high precision.

2.We have rich experience workers to adjusting the machine before delivery, they will test and check machines before delivery and hope customer will be easy to start new omega channel roll forming machine.