Decoration Suspended Furring Channel Ceiling Light Steel Keel Roll Forming Machine

Hat Furring Channels, Galvanized lightweight steel sections use as furring channel for drywall ceiling.. Drywall furring channel

commonly clips with metal furring channel clips to the underside of the U-Channel.

Zunsheng Company sells any type Hat Furring Channels roll forming machine and wants to make sure your job is done right the

first time; that’s why it’s so important that we talk before you purchase anything. These consultations are part of our service and

are offered at no cost to you.

Features Of Furring Channel Ceiling Light Steel Keel Roll Forming Machine:

1. The machine is stable,no noise,no shake.

2. Computer controlled continuous production, PLC display, operation is easy, running is steady and reliable,endurable.

3. Cutting machine is characterized by stable driving, easy operation.

4. Hydraulic system use the hydraulic pump, long operating life,no noise.

5. Zunsheng light steel keel forming machine produces very good flat ness products, with good bending pressure performance, can realize automatic fixed length cutting, automatic punching, high degree of automation. And the machine installation is quick and convenient. It greatly facilitates the operation and use of customers.

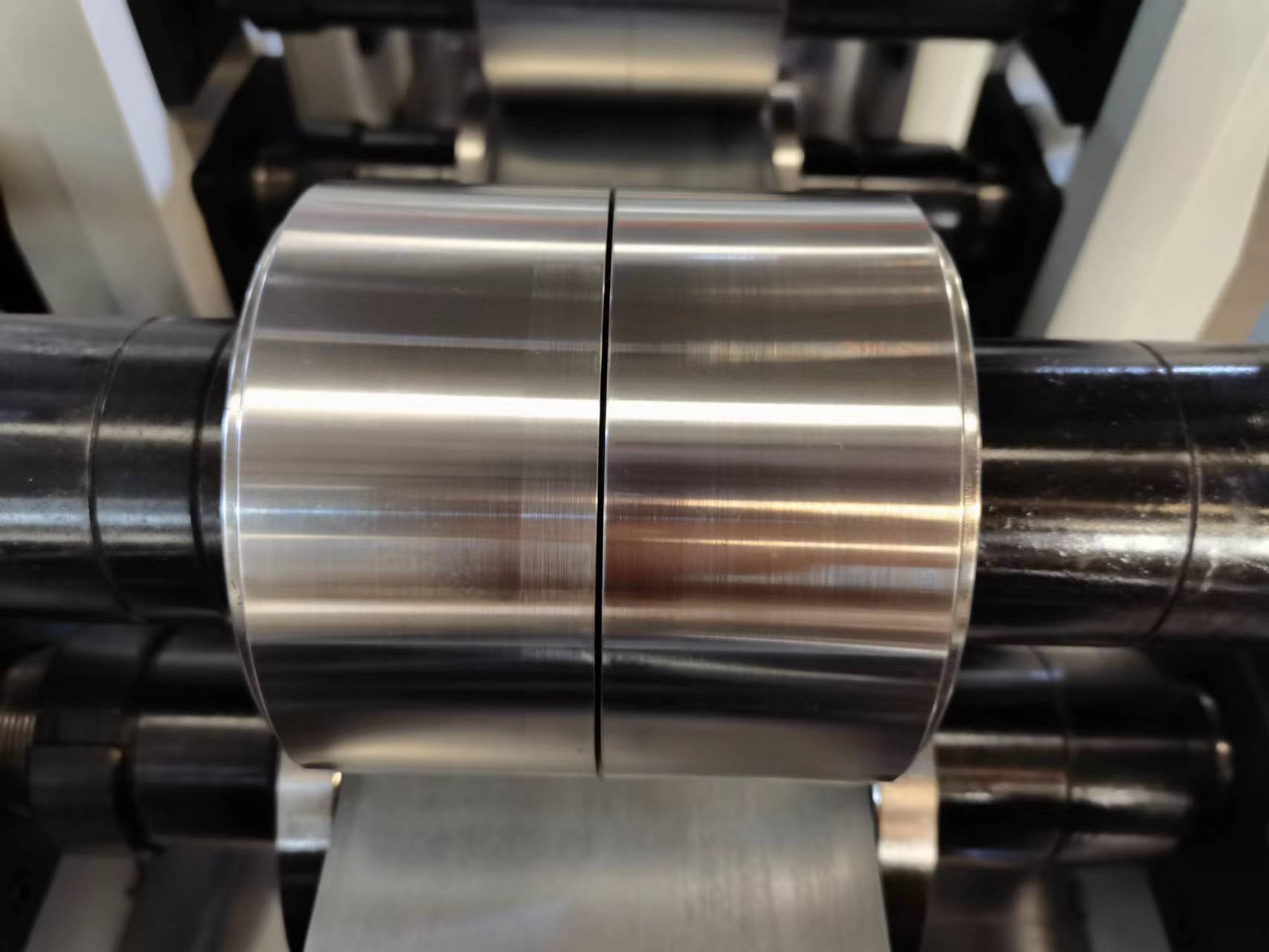

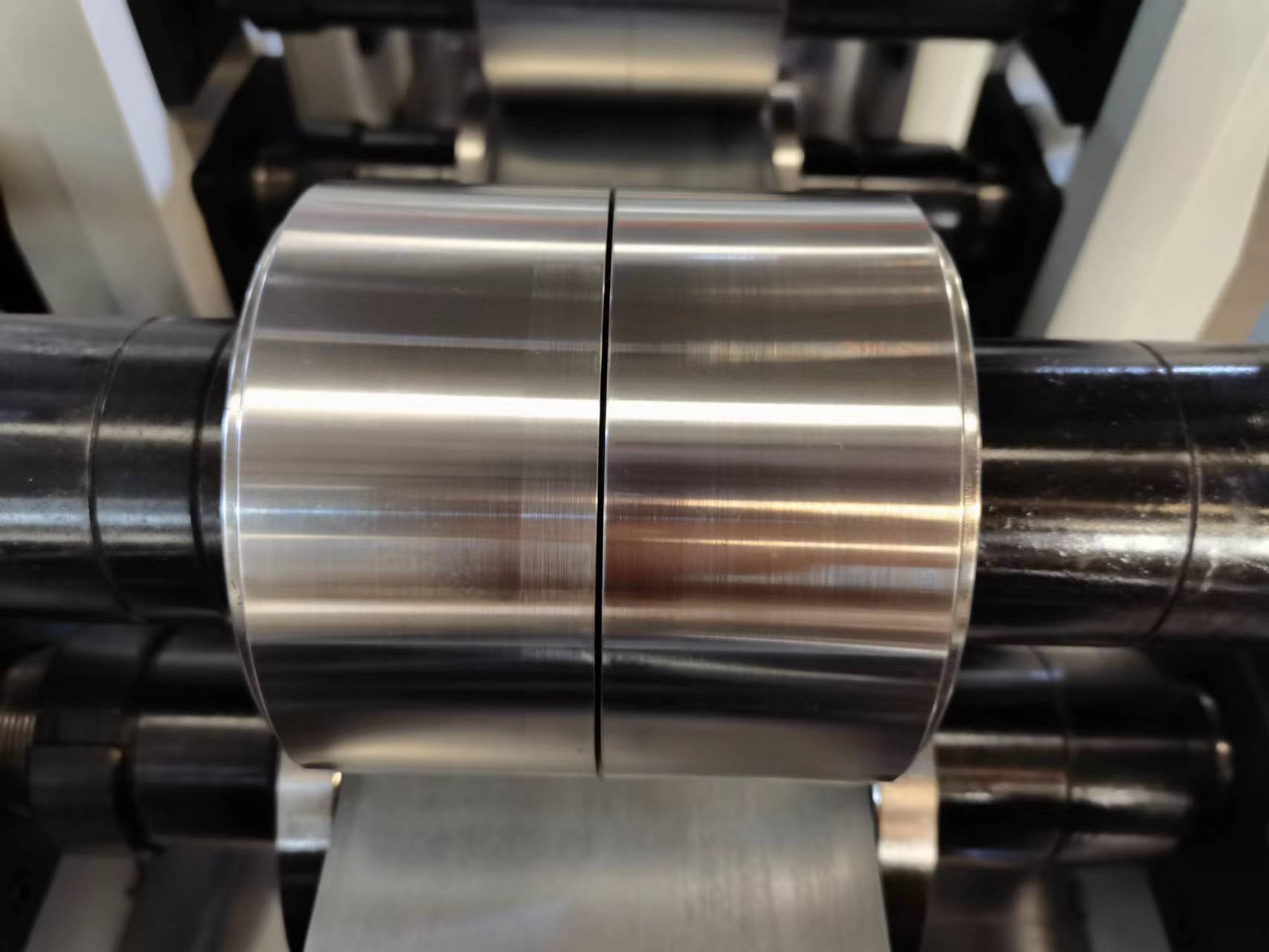

After all the rollers and shafts are finished by CNC lathes, they are hardened and tempered, then CNC lathes are finished again, and then they are precision processed with grinders, and finally they are chrome plated.Rollers and shafts processed by these processes can be more precisely roll former gauge steel.

We can provide you with a complete set of electric decoiler, inkjet printers and packing machine in one stop,and we can delivery all by one container.

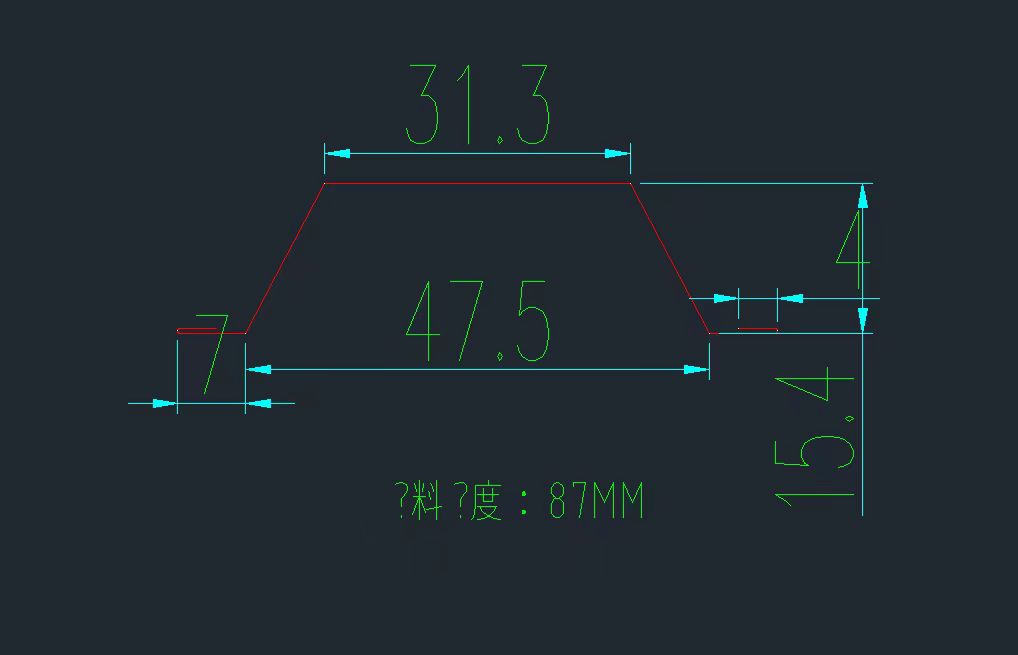

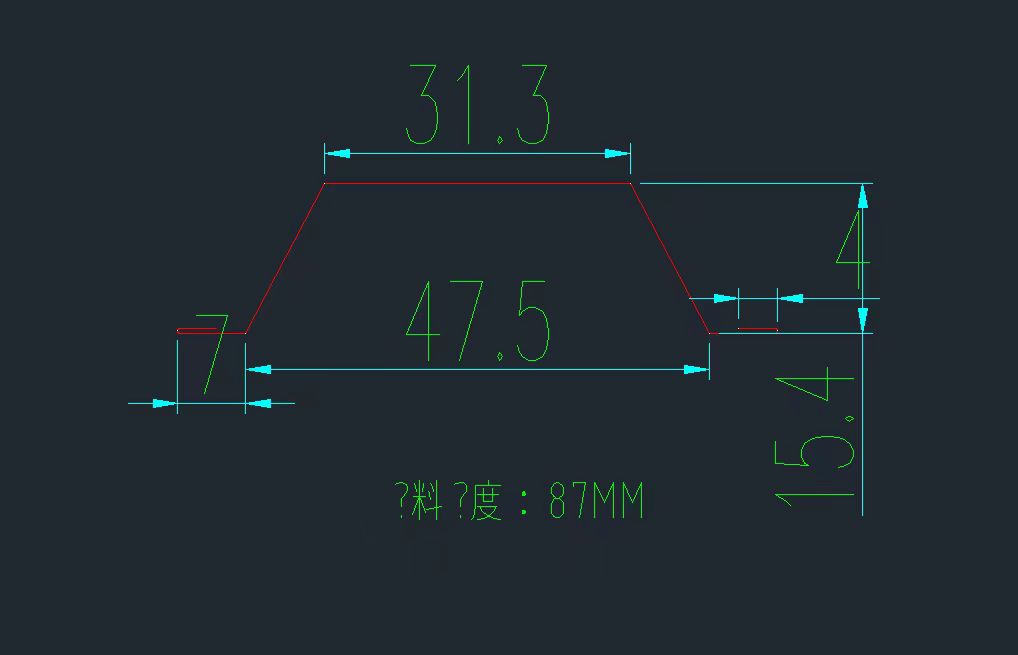

Specification

| Items | Furring Channel Roll Forming Machine |

| Total power | 5.5kw(3 phase,50 hz /60ha,380v/220v/230v/440v |

| Speed | 0-35m/min |

| Dimension(L*W*H) | 5.5m*1.2m*1.6m |

| Weight | 3.0 tons |

| Roller station | 12 pairs |

| Frame | Cast frame+tube/steel box |

| Material thickness | 0.4-0.8mm |

| Material width | Follow with design |

| Transmission system | Chain |

| Cutting system | Hydraulic cylinder(profile cutting system) Material SKD11 Japan |

| Control system | PLC,Xinjie |

| Runout table | Manual 3m,100kg load |

| Decoiler | Manual / Electrical,1.5 tons |

| Equipment |

| PLC | XINJIE(China) |

| Touch panel | XINJIE(China) |

| Electric motor | BOJIANG(China) |

| Encoder,relay | OMRON(Japan) |

| Hydraulic components | GUOWEI(China) |

| Cutting blades | SKD11(Japan) |

| Rollers | Cr12/GCr15 |

Product Uses

The furring system is a suspended steel framing gladdened with gypsum board sheets. The furring system is mostly uses for areas that need to be smooth ceiling without joints and where services to be concealed. The system is easy ,fast and flexible for installation and suitable for any interior design.

FAQ

1.How to match the inkjet printer and machine to work together?

We use the counter to connect the machine and the inkjet printer, then they can work together.

2.If we want to punch different sizes holes,how to do?

We will make different sizes hole dies,and you can change it when you need.

After Sell Service:

1. Engineer will give free training lessons to labors in buyer's factory.

2. The Buyer need buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD150 per day for engineer.

3. During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by incorrect operations, we will provide the buyer spare parts at cost price.

4. We will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide