Stud And Track Roll Forming Machine

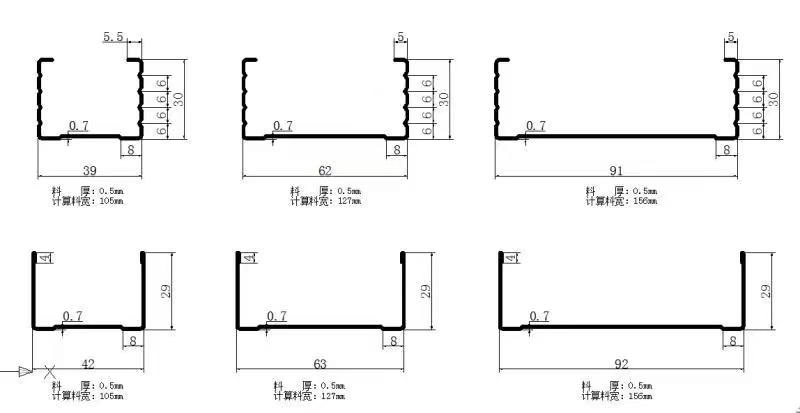

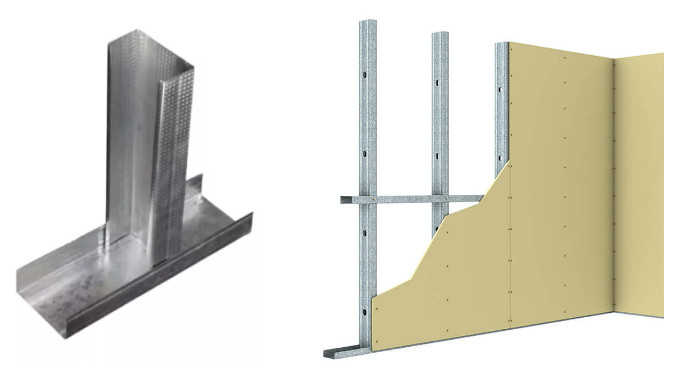

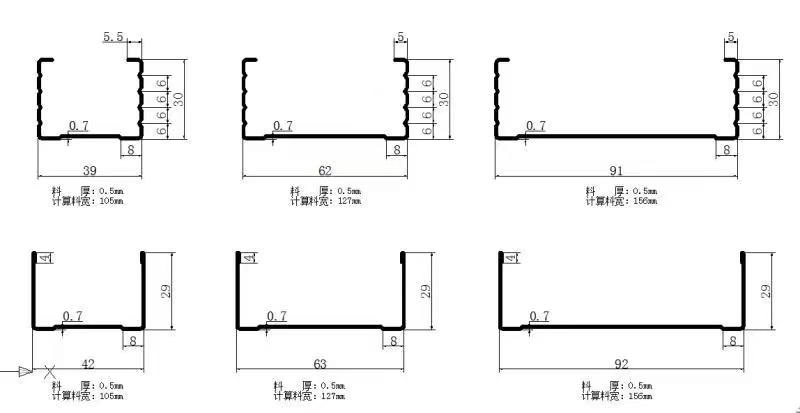

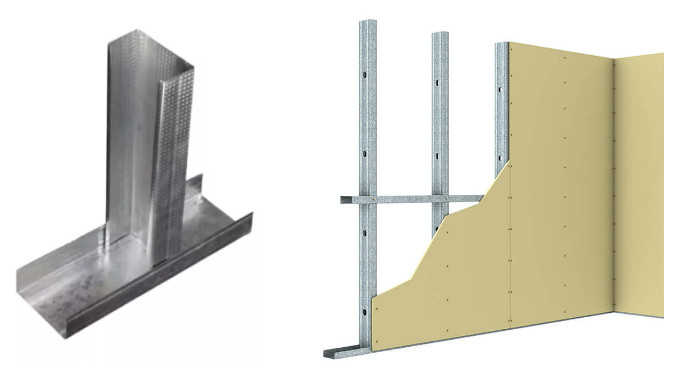

Stud and Track Roll Forming Machine is designed to produce the metal profiles in batch fully automatically. Metal profiles are precision-engineered, high-quality steel sections that are used to form the metal substructure of the Drywall or ceiling Systems. All metal sections produced from high-grade hot dip galvanized steel coils with the cold rolled forming process by the rolling forming machine.

Product Advantage

1.Stud and Track Framing Roll Forming Machine is produce different sizes drywall frames. We are use openable spaces,so it is easy to adjusting sizes.

2.We use a bady casting frame for machine structure, it is does not require shearing and welding,which ensures the metal studs and channels precision when machine is working.

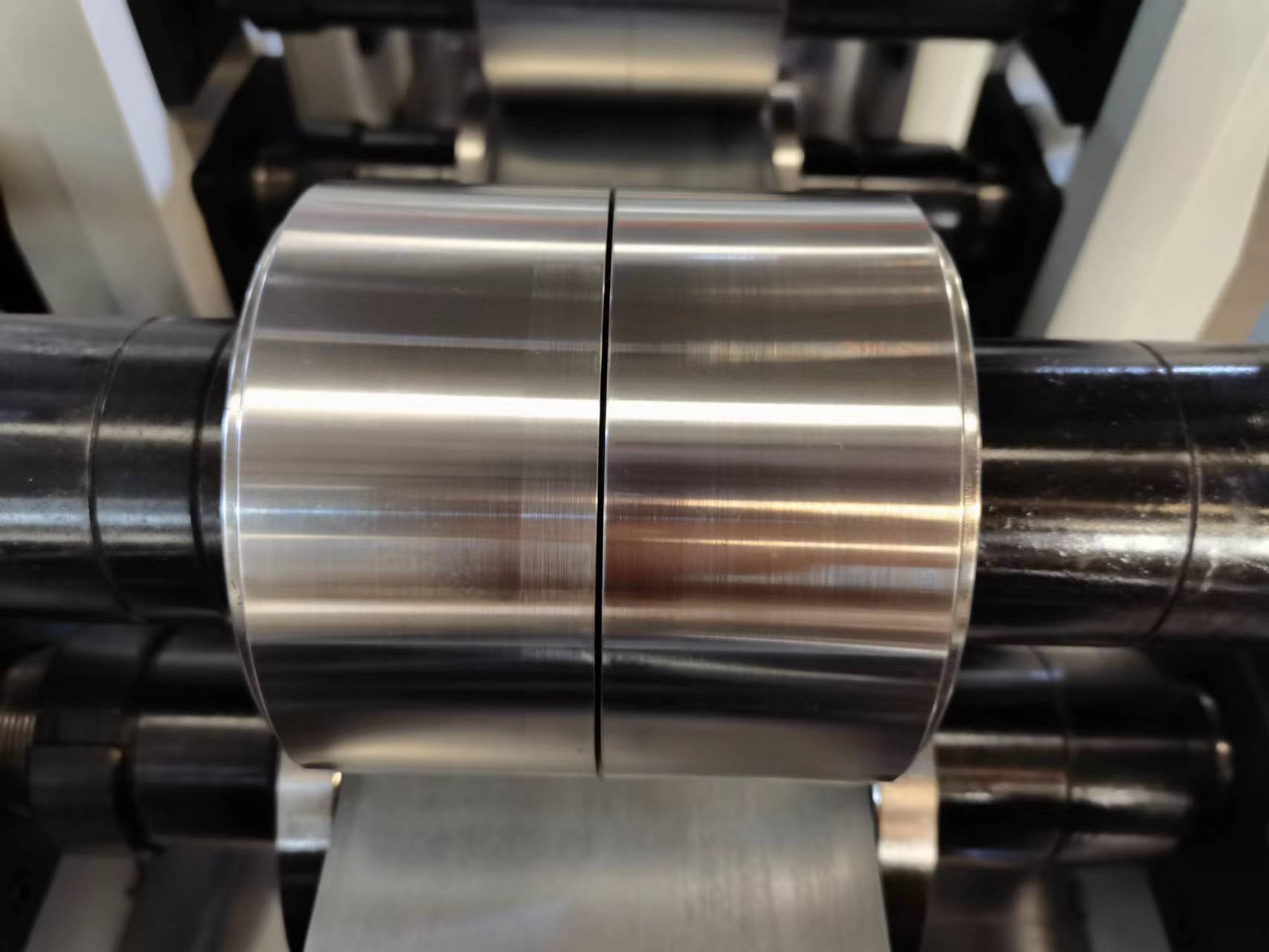

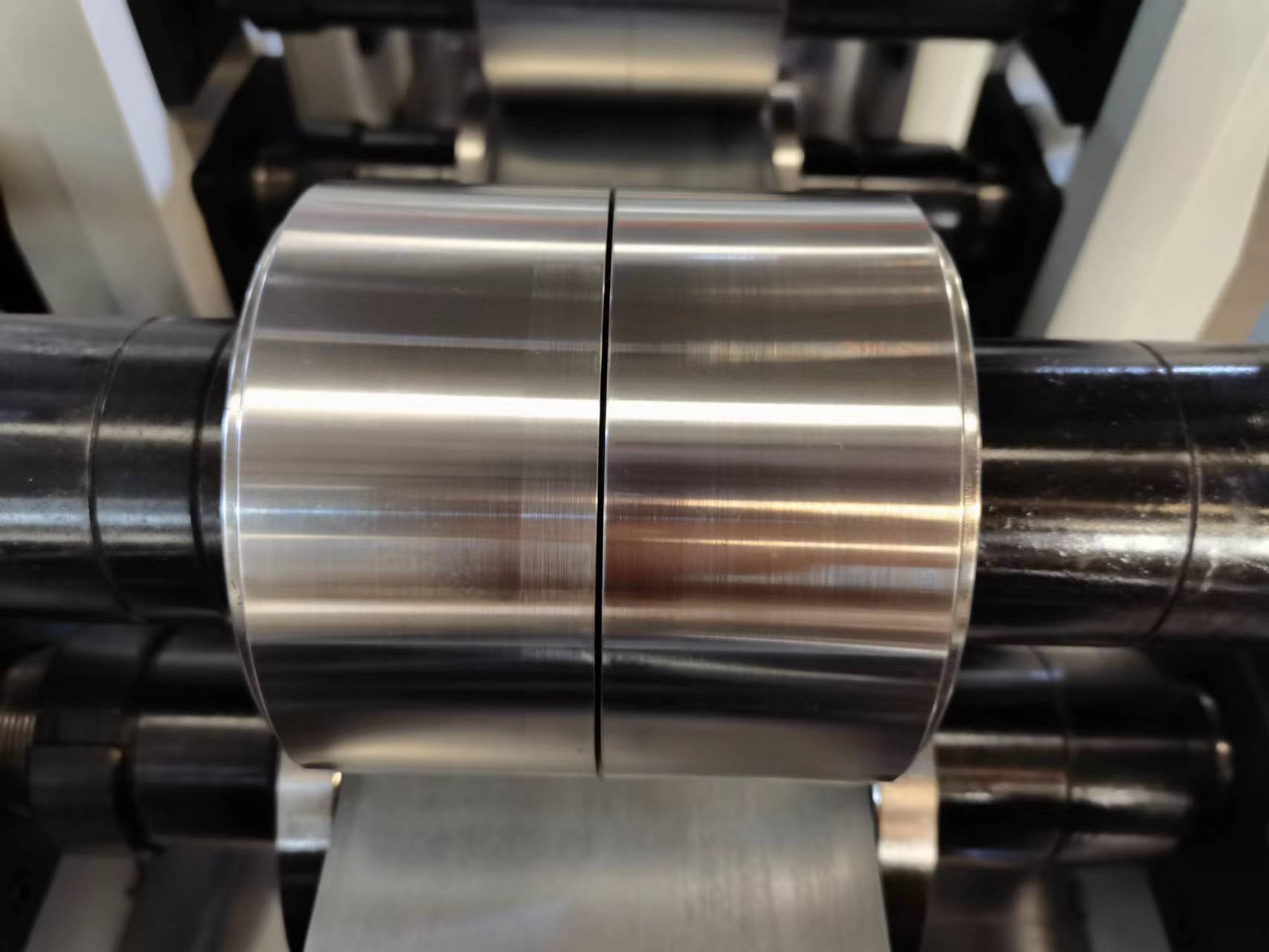

3.After all the rollers and shafts are finished by CNC lathes, they are hardened and tempered, then CNC lathes are finished again, and then they are precision processed with grinders, and finally they are chrome plated.Rollers and shafts processed by these processes can be more precisely roll former gauge steel.

4.We are free to choose the machine style. If your factory space is limited, you can choose our built-in machine, PLC, oil pump, motor, all built into the machine frame, saving space and beautiful.

5.The making machine is equipped with servo tracking for punching and cutting, which not only meets the customer's customization needs, but also meets the customer's high efficiency needs.

6.We can provide you with a complete set of electric decoiler, inkjet printers and packing machine in one stop,and we can delivery all by one container.

Specification

| Items | Stud and Track Roll Forming Machine |

| Total power | 5.5kw(3 phase,50 hz /60ha,380v/220v/230v/440v |

| Speed | 0-35m/min |

| Dimension(L*W*H) | 5.5m*1.2m*1.6m |

| Weight | 3.0 tons |

| Roller station | 12 pairs |

| Frame | Cast frame+tube/steel box |

| Material thickness | 0.4-0.8mm |

| Material width | Follow with design |

| Transmission system | Chain |

| Cutting system | Hydraulic cylinder(profile cutting system) Material SKD11 Japan |

| Control system | PLC,Xinjie |

| Runout table | Manual 3m,100kg load |

| Decoiler | Manual / Electrical,1.5 tons |

| Equipment |

| PLC | XINJIE(China) |

| Touch panel | XINJIE(China) |

| Electric motor | BOJIANG(China) |

| Encoder,relay | OMRON(Japan) |

| Hydraulic components | GUOWEI(China) |

| Cutting blades | SKD11(Japan) |

| Rollers | Cr12/GCr15 |

Product Uses

1. Light steel keel metal framing is a new type of building material. It is used in hotels, terminals, train stations, stations, playgrounds, shopping malls, and factories. , office buildings, old building renovation, interior decoration settings, ceilings and other places.

2. Light steel keel metal framing has the functions of light weight, high strength, adaptability to waterproof, shockproof, dustproof, sound insulation, sound absorption, constant temperature, etc.

3. It also has the advantages of short construction period and simple construction.

FAQ

1.How to match the inkjet printer and machine to work together?

We use the counter to connect the machine and the inkjet printer, then they can work together.

2.If we want to punch different sizes holes,how to do?

We will make different sizes hole dies,and you can change it when you need.