Imagine transforming flat metal sheets into complex profiles with precision and efficiency. That's the magic of roll forming! Customized roll forming solutions offer tailored machines for diverse profiles, enhancing production quality and versatility. In this post, you'll learn about roll forming, the significance of customization, and explore various profile solutions like Z Purlin Roll Forming Machines, C Purlin, and Roof Panel Roll Forming Machines.

Understanding Roll Forming Machines

Components of Roll Forming Machines

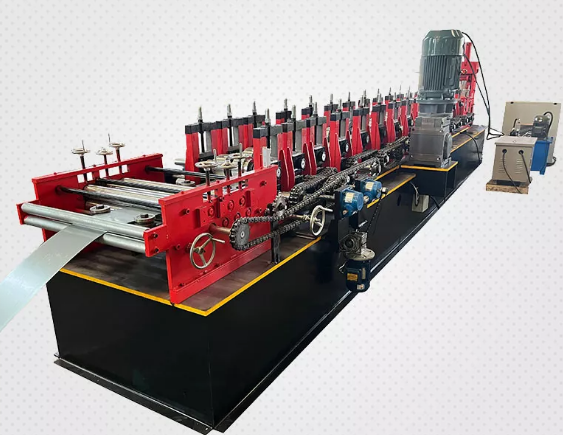

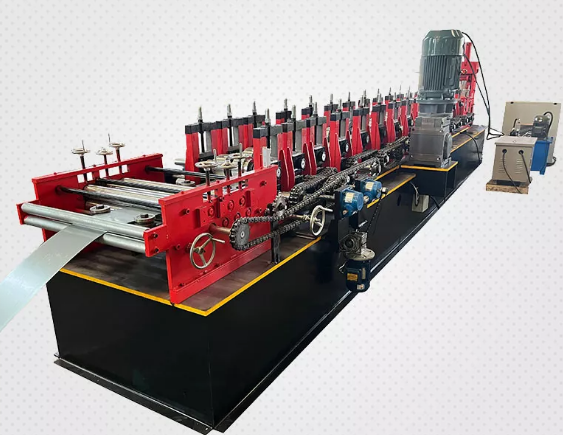

Roll forming machines consist of several key parts working together to shape metal strips into profiles. The main components include:

● Decoiler: Holds and unwinds the metal coil.

● Feeding Guide: Aligns the strip before it enters the rollers.

● Roll Stations: Multiple pairs of precisely machined rollers that gradually bend the metal strip into the desired shape.

● Drive System: Powers the rollers, typically using electric motors with variable speed control.

● Cutting Unit: Cuts the formed profile to specific lengths after shaping.

● Control System: PLC or computer-based system that manages speed, length, and machine parameters.

Each component is designed to ensure smooth, continuous operation and maintain high precision throughout the forming process.

How Roll Forming Machines Work

The process starts with a metal strip unwound from the decoiler. The strip passes through the feeding guide, ensuring proper alignment. It then moves through a series of roll stations. Each station bends the metal slightly more, shaping it step-by-step into the final profile.

Because the metal is formed at room temperature, the process is called cold roll forming. This preserves the metal’s strength and other properties. The number of roll stations depends on the complexity of the profile; more complex shapes need more stations.

After shaping, the profile reaches the cutting unit, where it's cut to length. Some machines include additional units for punching holes or embossing features during the forming process.

Types of Roll Forming Machines

Several types of roll forming machines exist to suit different production needs:

● Single-Stand Machines: One set of rollers forming the profile in one pass, suitable for simple shapes and thin materials.

● Multi-Stand Machines: Multiple roll stands arranged in a line for complex profiles needing gradual forming.

● Vertical Roll Formers: Rollers arranged vertically, often used for long profiles or specific shapes.

● Combination Machines: Integrate roll forming with additional processes like punching, notching, or welding.

Machine selection depends on the profile’s complexity, material type, thickness, and production volume.

Z Purlin Roll Forming Machines

Features of Z Purlin Machines

Z purlin roll forming machines are designed specifically to produce Z-shaped steel profiles used mainly in construction. These machines feature:

● Precision Rollers: Multiple sets of rollers shaped to form the Z profile accurately.

● High-Speed Operation: Capable of continuous production to meet large volume demands.

● Adjustable Settings: Allow changes in profile dimensions such as flange width, lip size, and thickness.

● Integrated Cutting Units: Cut profiles to exact lengths without stopping the line.

● Automatic Control Systems: PLC-based controls manage speed, length, and profile consistency.

● Durability: Robust frame and components ensure long machine life even under heavy use.

These features ensure Z purlins are produced with consistent quality, tight tolerances, and high efficiency.

Applications in Construction

Z purlins are widely used in the construction industry due to their strength and versatility. Common applications include:

● Roof and Wall Support: Acting as horizontal beams supporting roofing sheets or wall panels.

● Steel Frame Buildings: Providing structural support for warehouses, factories, and commercial buildings.

● Bridging Elements: Connecting other structural components to improve stability.

● Modular Construction: Used in prefabricated buildings for lightweight yet strong framing.

Their Z shape allows for easy overlapping and interlocking during assembly, making installation faster and more secure.

Customization Options

Customization is a key advantage of Z purlin roll forming machines. Options include:

● Profile Dimensions: Tailoring flange widths, heights, and lip sizes to specific structural requirements.

● Material Thickness: Adjusting to accommodate different steel gauges for strength or weight considerations.

● Hole Punching: Integrating punching units to add holes or slots for fasteners during forming.

● Surface Treatments: Applying coatings or finishes inline after forming for corrosion resistance.

● Batch Flexibility: Programming machines to switch between different Z purlin designs quickly.

These customization features allow manufacturers to produce Z purlins optimized for their clients’ building codes, load requirements, and installation preferences.

C Purlin Roll Forming Machines

Characteristics of C Purlin Machines

C purlin roll forming machines produce C-shaped steel profiles commonly used in construction and industrial applications. These machines feature:

● Precision Rollers: Designed to shape metal strips into consistent C profiles with exact dimensions.

● Adjustable Forming Stations: Allow variation in flange width, height, and lip size to meet specific structural needs.

● Robust Frame: Ensures stability and accuracy during high-speed production.

● Integrated Cutting Systems: Automatically cut profiles to required lengths without interrupting the forming process.

● Control Systems: PLC-based controls manage speed, length, and profile consistency for repeatable quality.

● Versatile Material Handling: Capable of processing various steel grades and thicknesses.

These characteristics enable manufacturers to produce high-quality C purlins efficiently and with tight tolerances.

Structural Benefits

C purlins are valued for their structural advantages, including:

● High Strength-to-Weight Ratio: Their shape offers excellent load-bearing capacity while minimizing material usage.

● Ease of Installation: Open-back design allows for quick fastening and connection to other structural elements.

● Flexibility: Suitable for spanning moderate distances in roofing, wall framing, and mezzanine floors.

● Compatibility: Easily integrates with other metal framing components, enabling modular construction.

● Corrosion Resistance: Can be coated or galvanized to withstand harsh environments.

● Cost Efficiency: Their design reduces material and labor costs compared to traditional beams.

These benefits make C purlins a preferred choice in many building projects requiring durable yet lightweight framing solutions.

Industry Applications

C purlin roll forming machines serve various industries, such as:

● Construction: Used extensively for roof and wall support in warehouses, commercial buildings, and residential structures.

● Agriculture: Framework for barns, storage sheds, and greenhouses.

● Manufacturing: Structural support for industrial racks, conveyor systems, and equipment housings.

● Transportation: Components in vehicle trailers and container frames.

● Renewable Energy: Support structures for solar panels and wind turbine foundations.

Their versatility and strength make C purlins indispensable across sectors needing reliable structural profiles.

Tip: When selecting a C purlin roll forming machine, prioritize models offering adjustable forming stations and integrated cutting units to ensure flexibility for different profile sizes and efficient production workflows.

Roof Panel Roll Forming Machines

Design and Functionality

Roof panel roll forming machines are designed to produce metal roofing panels efficiently and accurately. These machines shape flat metal sheets into profiles that provide strength, durability, and weather resistance for roofing systems. The design of these machines includes:

● Multiple Roll Stations: Each station gradually bends the metal sheet into the desired roof panel shape, such as trapezoidal, corrugated, or standing seam profiles.

● Precision Rollers: Crafted to match specific panel designs, ensuring consistent profile dimensions and smooth surfaces.

● Decoiler and Feeding System: Feeds metal coils steadily into the machine for continuous production.

● Cutting Unit: Automatically cuts panels to set lengths without interrupting the forming process.

● Control System: Often PLC-based, it manages speed, length, and panel profile parameters for consistent output.

● Optional Features: Some machines include punching units to create holes for fasteners or accessories during forming.

These components work together to produce roof panels that meet architectural and structural standards while optimizing production speed.

Advantages for Roofing Solutions

Using roof panel roll forming machines offers numerous benefits for roofing manufacturers and builders:

● High Production Efficiency: Continuous forming process enables large volumes of panels to be produced quickly.

● Consistent Quality: Precision rollers and automated controls ensure panels have uniform dimensions and fit perfectly during installation.

● Material Optimization: Roll forming at room temperature preserves the metal’s strength and reduces waste.

● Customization Capability: Machines can be adjusted to produce various panel profiles and thicknesses to suit different roofing needs.

● Improved Weather Resistance: Profiles are designed to channel water effectively and withstand wind loads.

● Reduced Installation Time: Panels are cut to exact lengths and often include features like pre-punched holes, speeding up onsite assembly.

These advantages help roofing companies deliver durable, cost-effective, and aesthetically pleasing roofing systems.

Customization and Efficiency

Customization is key for roof panel roll forming machines, allowing manufacturers to meet diverse project requirements:

● Profile Variations: Machines can be tailored to form different panel shapes, such as ribbed, snap-lock, or tile-effect designs.

● Material Thickness Range: Adjustable settings accommodate metals from thin gauges for residential roofs to thicker sheets for industrial applications.

● Integrated Punching and Notching: Adding holes, slots, or cutouts inline reduces secondary processing and labor costs.

● Variable Panel Lengths: Programmable cutting units enable production of panels in various lengths based on project specifications.

● Surface Treatment Compatibility: Machines can handle coated or pre-painted metals without damaging finishes.

Efficiency gains come from quick changeovers between profiles and automated control systems that minimize downtime and errors.

Advantages of Customized Roll Forming Solutions

Cost-Effectiveness

Customized roll forming solutions can significantly reduce production costs. By designing machines tailored to specific profiles, manufacturers avoid unnecessary steps and material waste. The process integrates multiple functions—such as forming, cutting, and punching—into one seamless operation. This reduces labor, handling, and secondary processing expenses. Additionally, producing profiles in continuous lengths minimizes scrap and optimizes raw material usage. Over large production runs, these efficiencies translate into substantial savings. Custom tooling ensures the profile is made right the first time, avoiding costly rework or modifications.

Precision and Quality

Tailored roll forming machines deliver exceptional precision and consistent quality. Custom rollers and forming stations are engineered to exact profile dimensions, maintaining tight tolerances throughout production. Automated control systems monitor parameters like speed and length, ensuring uniform output. This precision is critical for profiles used in structural or load-bearing applications, where accuracy affects safety and performance. Furthermore, inline features like hole punching or embossing are integrated during forming, eliminating errors from separate processes. The cold roll forming process preserves material properties, resulting in strong, durable profiles with excellent surface finishes.

Versatility Across Industries

Customized roll forming solutions adapt easily to diverse industry needs. Whether producing Z purlins for construction, C purlins for industrial framing, or specialized roof panels, custom machines handle unique profile shapes and sizes. They accommodate various materials, thicknesses, and coatings, enabling manufacturers to meet specific project requirements. This versatility supports industries such as automotive, agriculture, renewable energy, and manufacturing. Customization also allows quick changeovers between different profiles or batch sizes, enhancing responsiveness to market demands. By investing in tailored roll forming equipment, companies gain a competitive edge through flexibility and expanded product offerings.

Choosing the Right Roll Forming Machine

Factors to Consider

Selecting the right roll forming machine requires careful evaluation of several key factors:

● Profile Complexity: The shape and intricacy of the desired profile influence the machine type. Complex profiles need machines with multiple roll stations and precise tooling.

● Material Type and Thickness: Different metals and thicknesses require machines built to handle specific loads and forming forces.

● Production Volume: High-volume runs benefit from machines with automated features and high-speed capabilities to maximize efficiency.

● Flexibility: Machines with adjustable roll stations and quick changeover options allow production of various profiles on the same line.

● Space and Layout: Consider the available factory floor space and the machine’s footprint to ensure smooth integration.

● Budget: Balance upfront costs against long-term benefits like durability, maintenance, and automation features.

● Technical Support and Training: Reliable supplier support and operator training can prevent downtime and maintain product quality.

Matching Machine to Profile Needs

Aligning the machine’s capabilities with profile requirements ensures optimal performance:

● Simple Profiles: Single-stand or fewer roll station machines suffice for basic shapes and thinner materials.

● Complex Profiles: Multi-stand or combination machines with integrated punching or cutting units handle detailed profiles efficiently.

● High Precision Needs: Machines with advanced control systems and precision rollers provide consistent dimensions and tight tolerances.

● Custom Profiles: Machines designed for flexibility and tooling customization accommodate unique shapes and batch variations.

● Material Handling: Ensure the machine supports the metal type and thickness you plan to use, including coated or pre-painted sheets.

Supplier Selection Tips

Choosing the right supplier is as important as selecting the machine:

● Experience and Reputation: Look for suppliers with proven expertise in your industry and profile types.

● Customization Capability: Suppliers who design and manufacture their own tooling can better tailor machines to your needs.

● After-Sales Service: Strong technical support, maintenance, and spare parts availability reduce downtime risks.

● Quality Certifications: ISO or other quality management certifications indicate commitment to standards.

● Lead Times and Delivery: Reliable delivery schedules and flexible production timelines keep your projects on track.

● References and Case Studies: Request examples of similar projects to assess supplier performance and machine reliability.

● Training and Documentation: Ensure comprehensive operator training and clear manuals come with the machine.

Conclusion

Customized roll forming solutions offer cost-effectiveness, precision, and versatility, making them ideal for diverse industry applications. Future trends in roll forming emphasize automation and flexibility to meet evolving market demands. Zunsheng provides advanced roll forming machines that deliver exceptional value through tailored designs and robust support services. Their products ensure high-quality profiles with consistent dimensions, enhancing production efficiency and adaptability. Investing in Zunsheng's solutions enables companies to stay competitive and responsive to changing profile requirements.

FAQ

Q: What is a Roll Forming Machine?

A: A Roll Forming Machine is equipment used to shape metal strips into specific profiles through a continuous bending process, maintaining the metal's strength by forming it at room temperature.

Q: How do Z Purlin Roll Forming Machines benefit construction?

A: Z Purlin Roll Forming Machines produce Z-shaped steel profiles, offering strength and versatility for roof and wall support, enhancing structural stability in construction.

Q: Why choose C Purlin Roll Forming Machines for industrial applications?

A: C Purlin Roll Forming Machines create C-shaped profiles with high strength-to-weight ratios, ideal for industrial framing and quick installation.

Q: What are the advantages of Roof Panel Roll Forming Machines?

A: Roof Panel Roll Forming Machines offer high production efficiency, consistent quality, and customization, producing durable panels for various roofing needs.