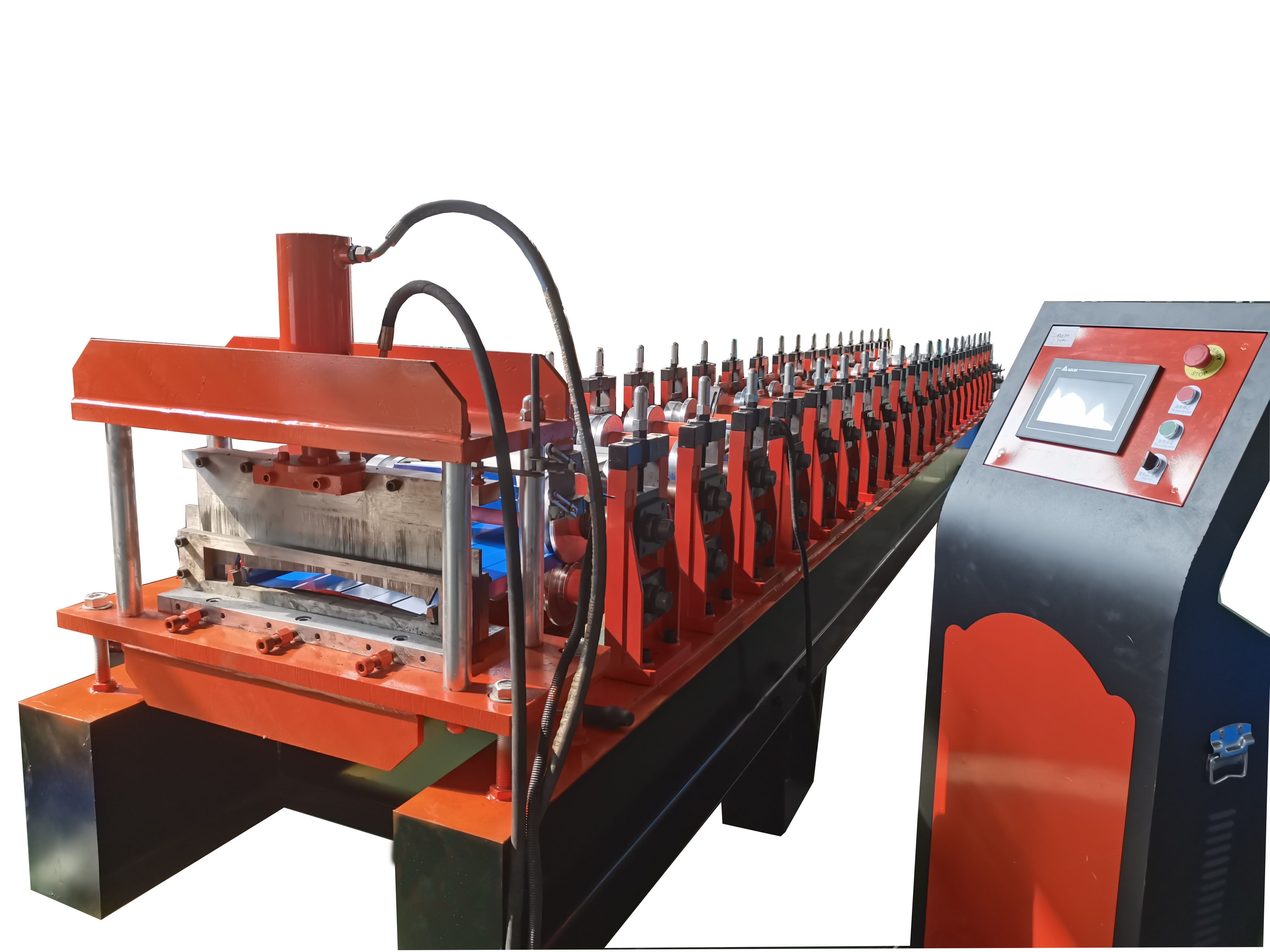

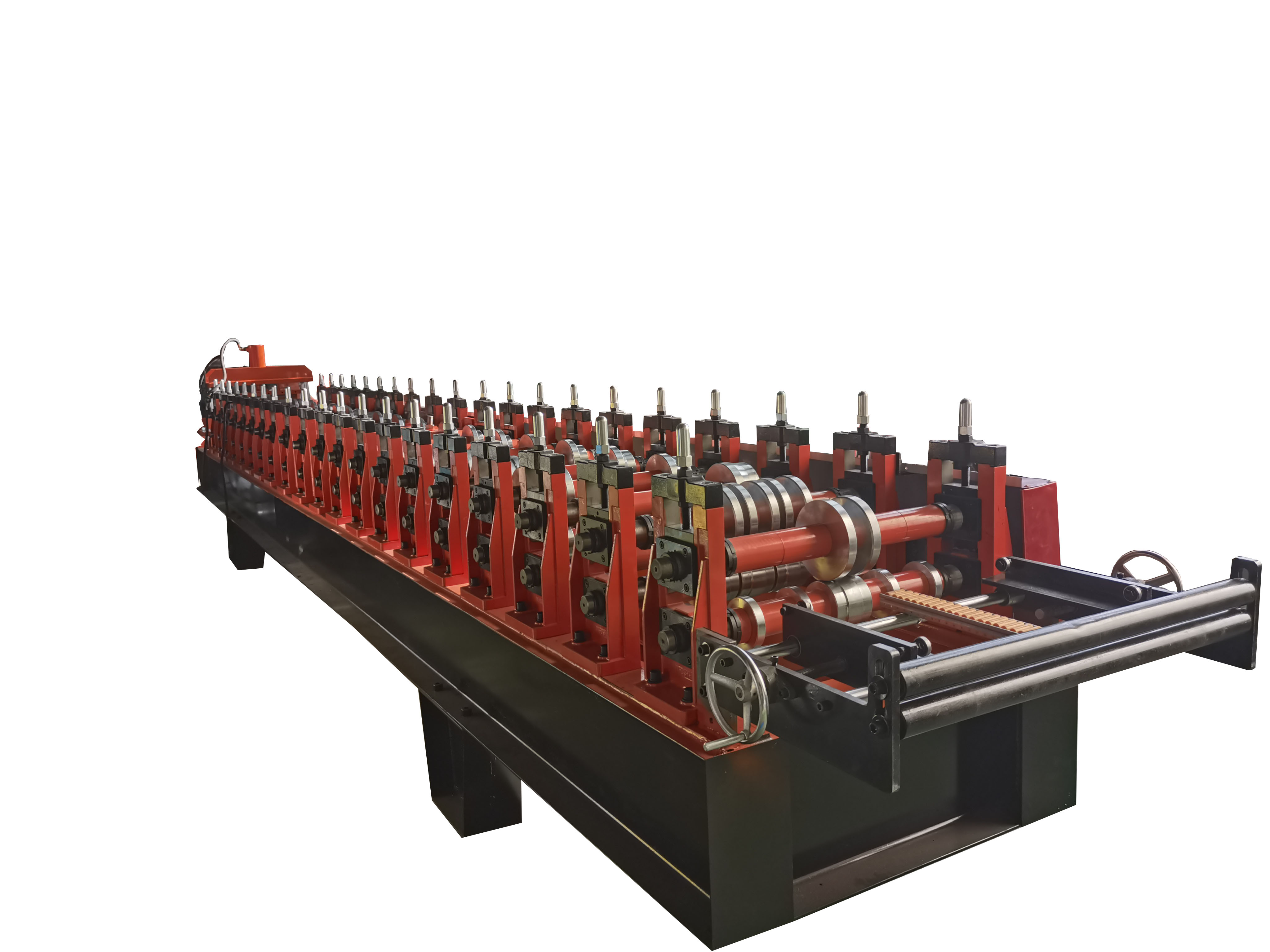

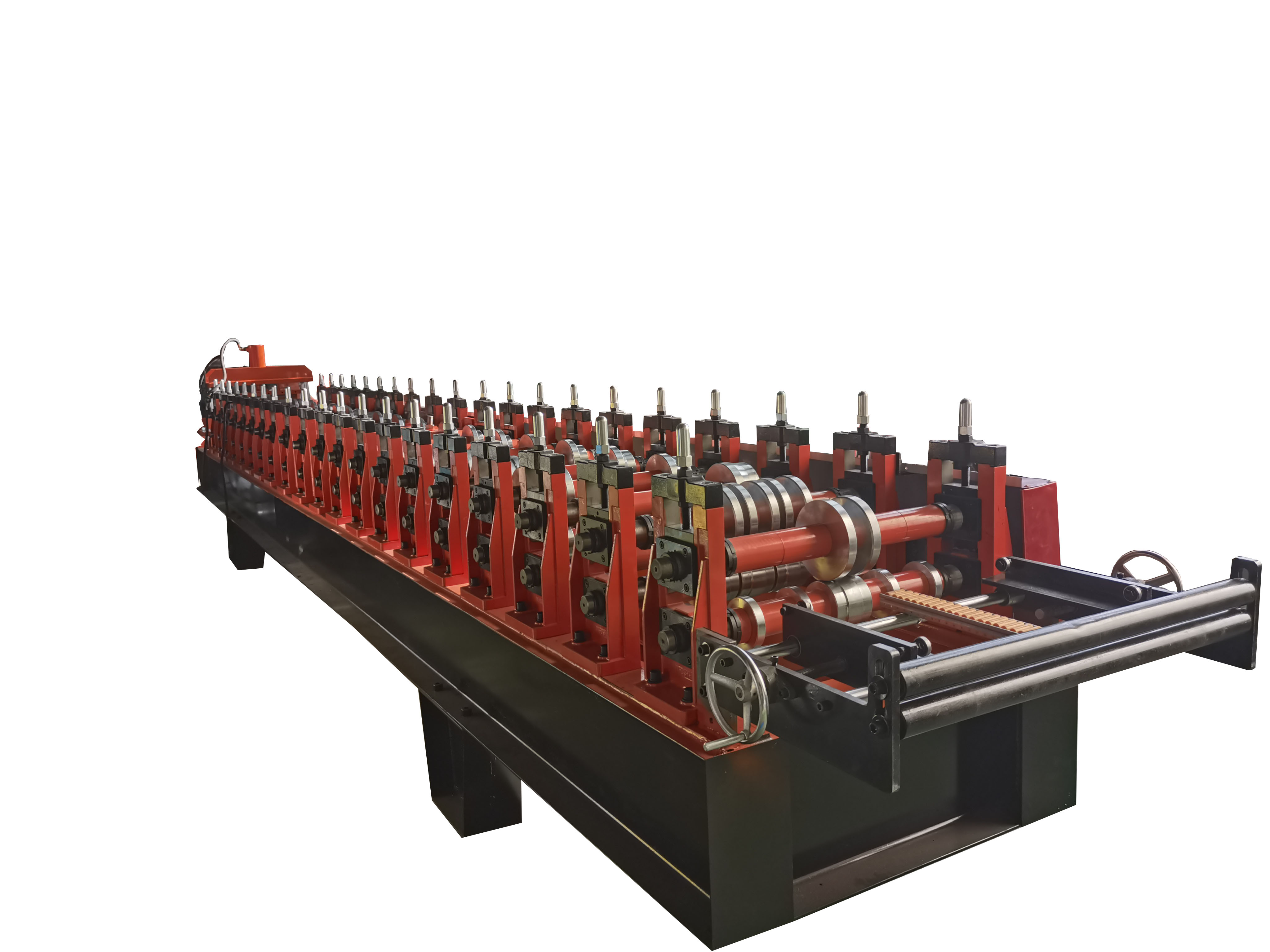

Steel Tile Aluminum Wall Panel Cladding Cold Roll Forming Machine

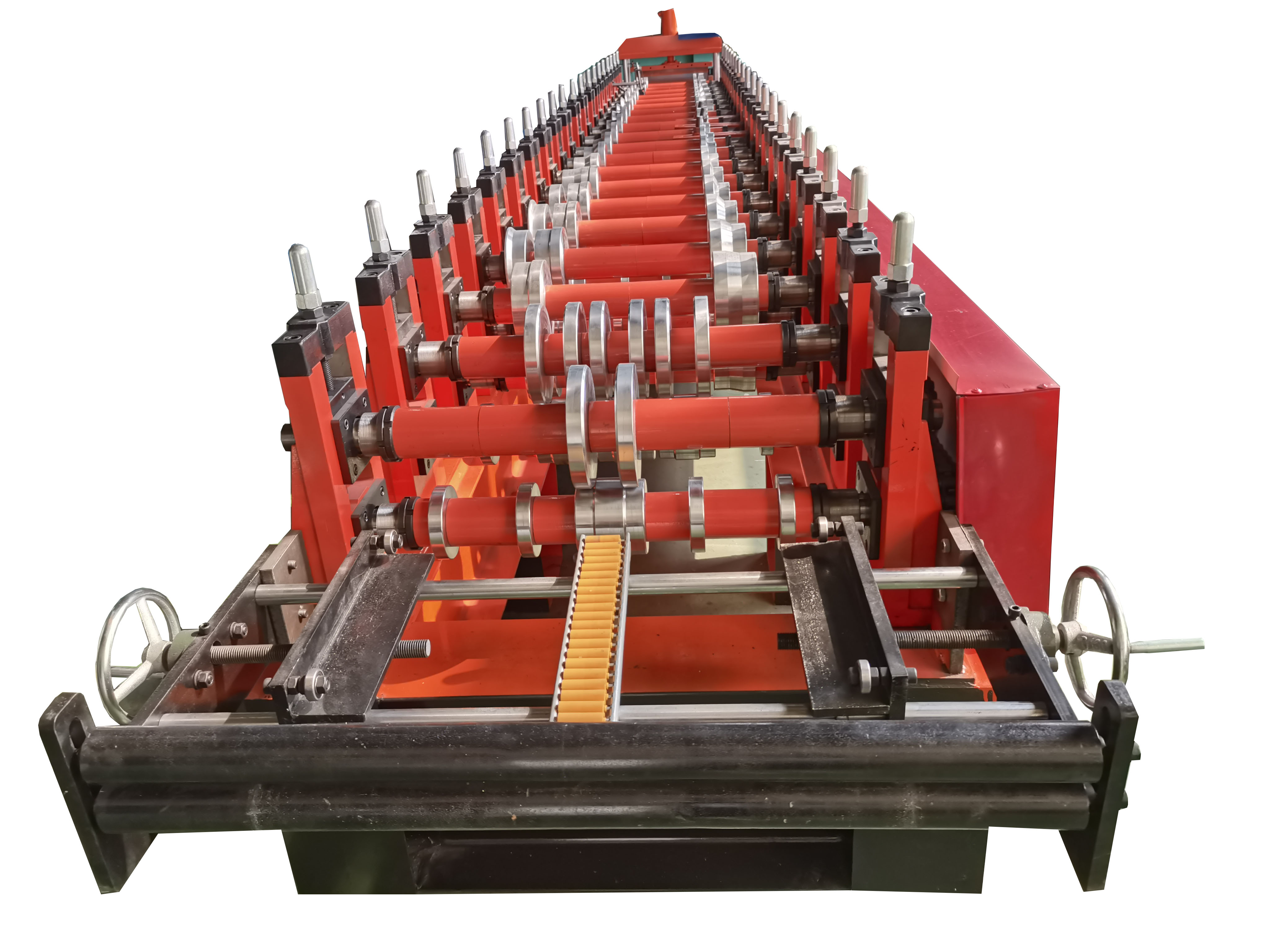

Our intention of designing the wall panel cladding cold roll forming machine is to make it easier for customers to operating and the machine working more stable.

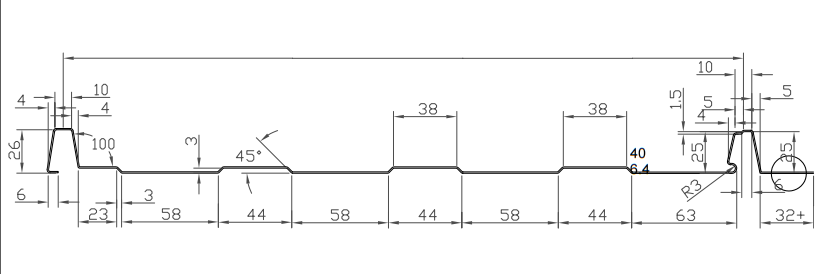

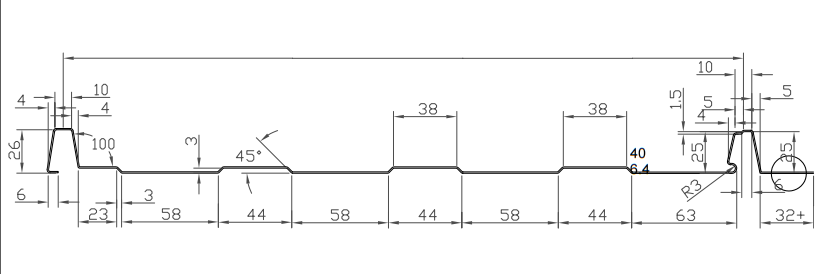

Self lock cladding panel design offered by customer, and we designed rollers follow with these sizes.

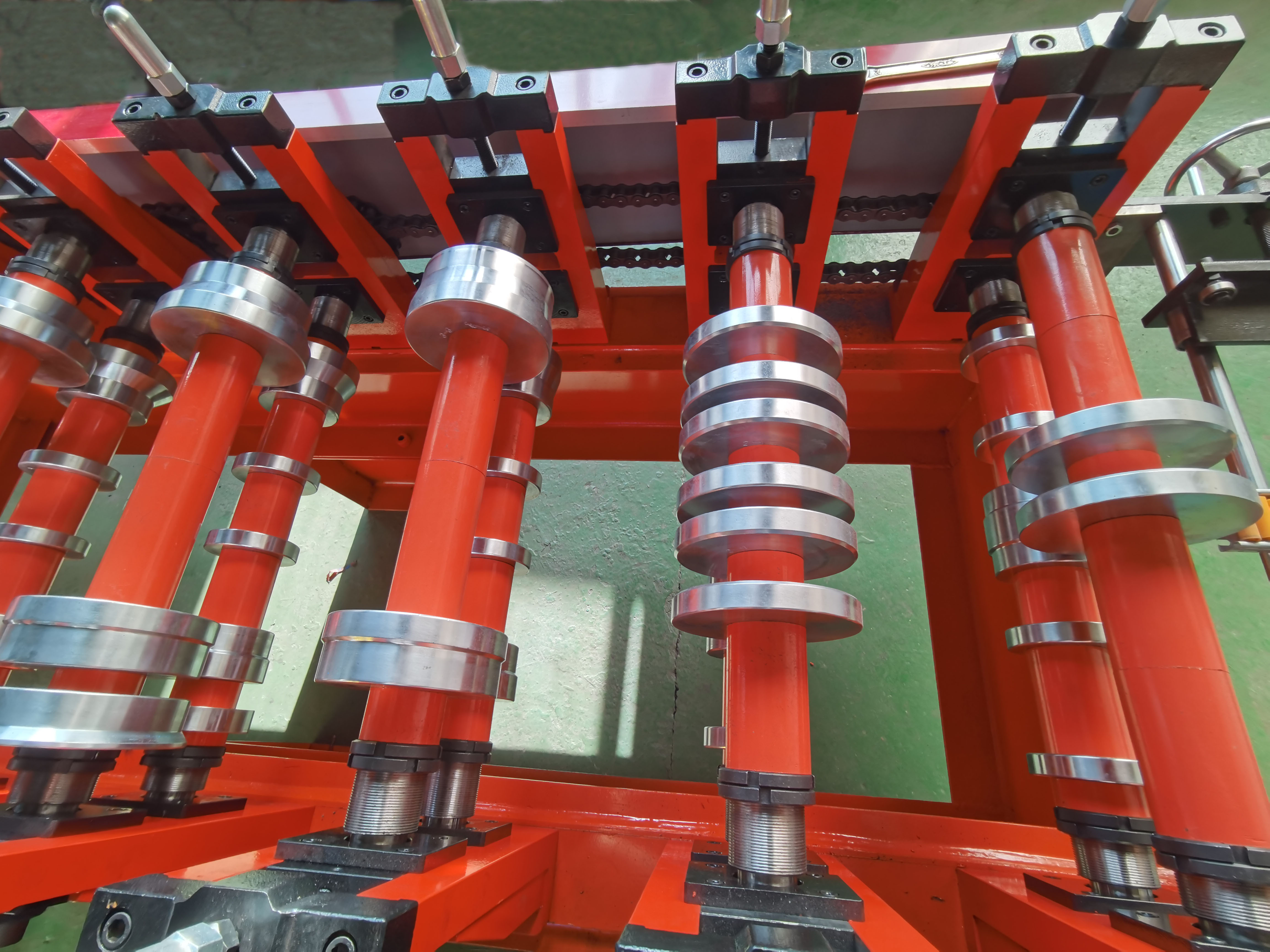

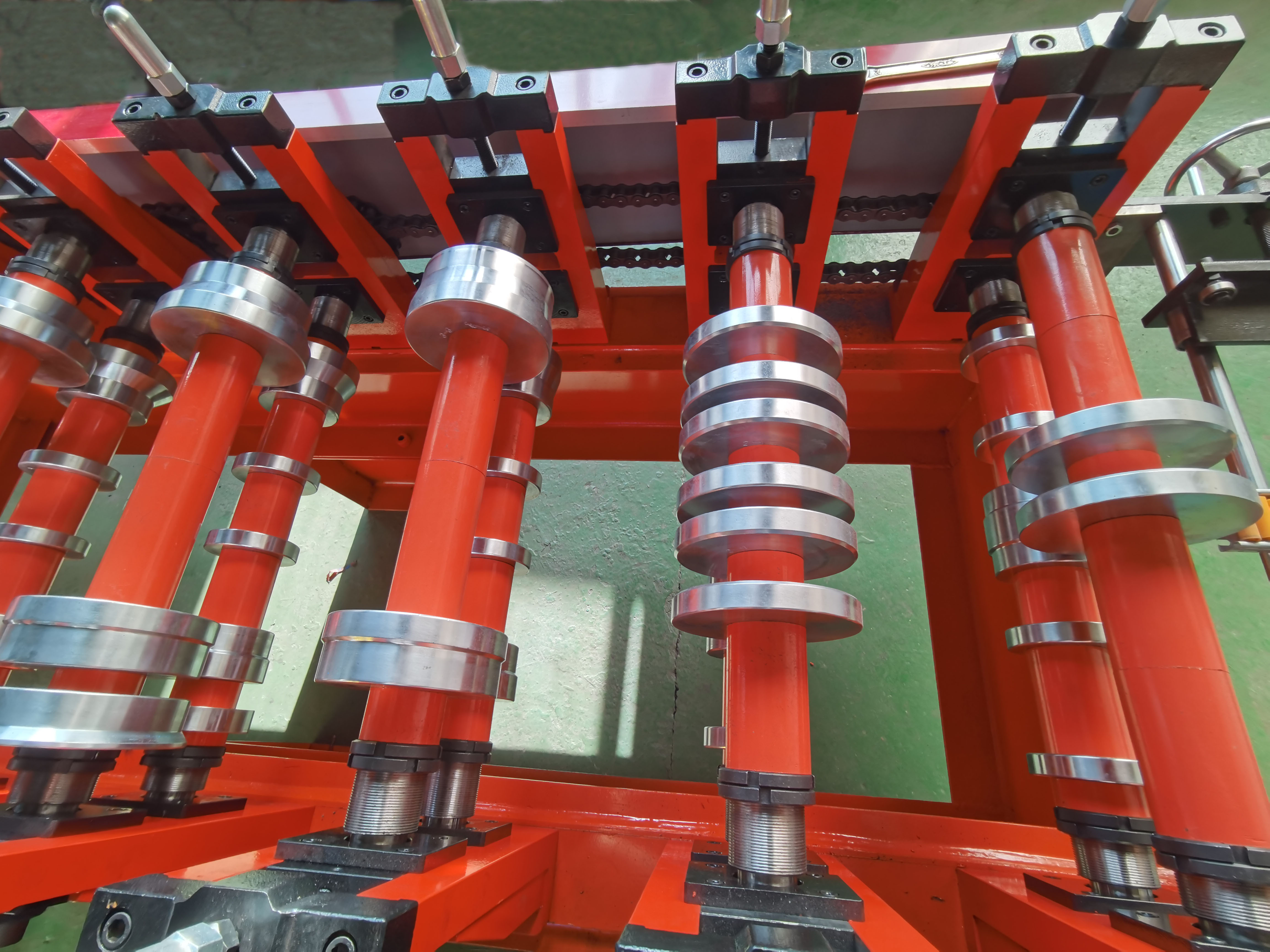

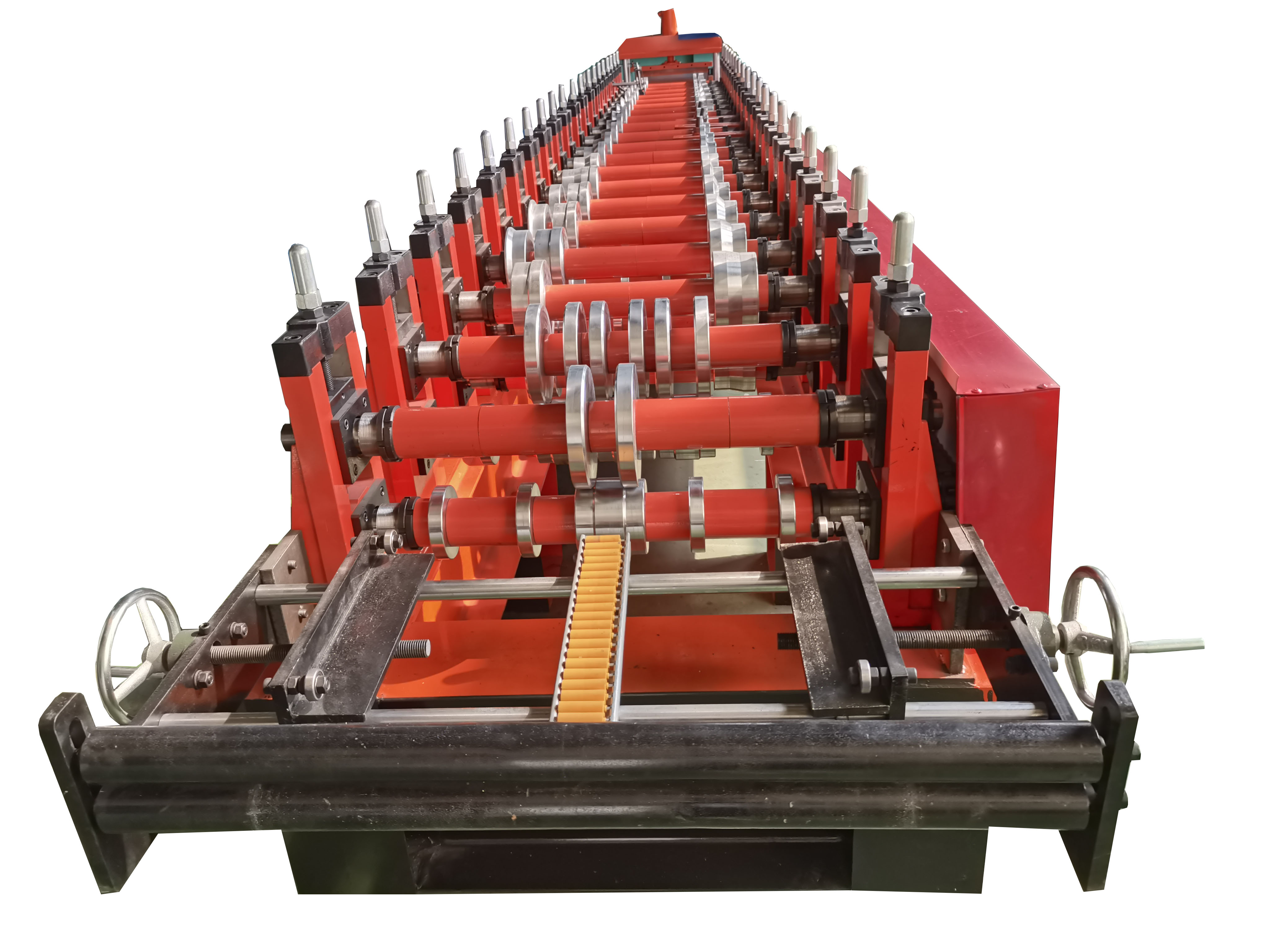

All rollers processed by CNC Milling, with hard treatment and chrome coating.

All stations use casting frame with double bearings, casting frame is the best powerful structure for roll forming machine, it is without cutting and welding,so it is can make sure roll forming precision and let machine working in stable.

Adjustable feeder and fix coil well,it is not easy to swing when coil going to roll forming machine.

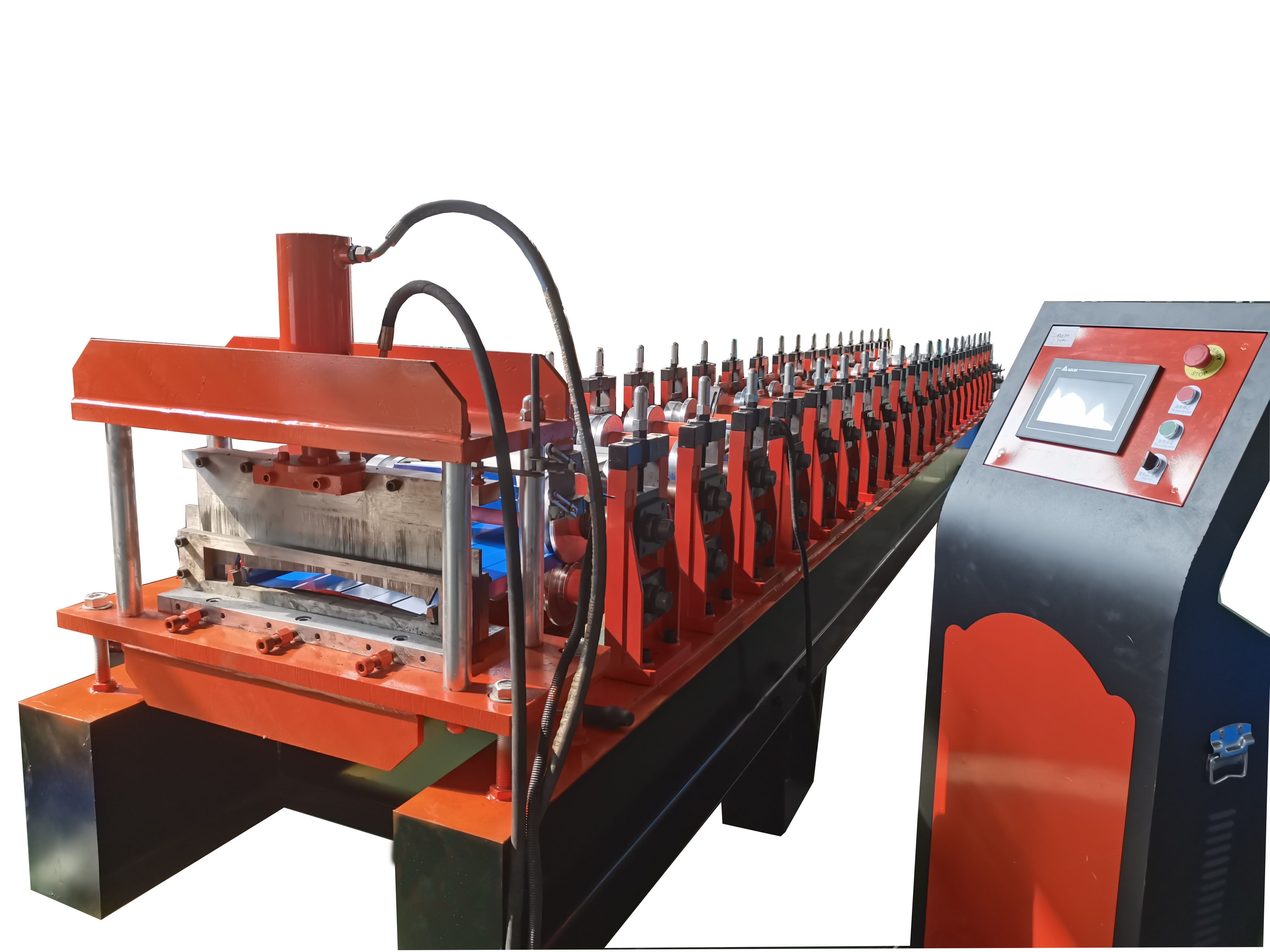

Hydraulic system to driven cutting, cutting blade use Cr12mov material with hard treatment, it is cutting cladding panel in well,no burr.

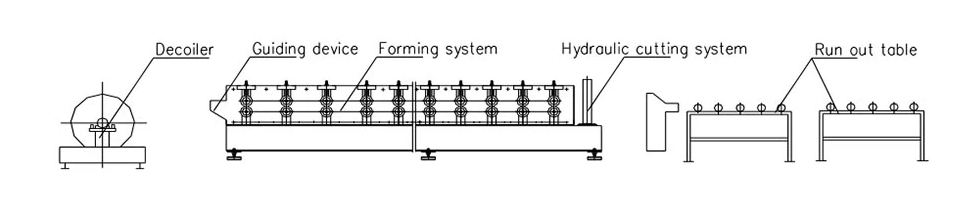

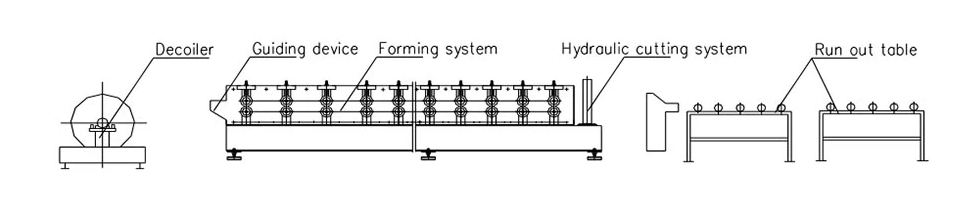

Working Flow:

Decoiler---Feeder---Roll Forming Machine---Hydraulic cutting---Run out table

Specification:

No. | Item | Unit |

|

| Color Steel Board Roll Forming Machine |

1. | Material Of Processing |

| PPGI,Galvanized steel |

2. | Profile Type | mm | As your design |

3. | Feed coil Thickness | mm | 0.46-0.75 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 50 |

7. | Roll Station | No. | 18 |

8. | Rolling material |

| 45#steel |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed |

| 8-12m/min |

11. | Drive Type of Roll Forming Machine |

| Chain |

12. | Power of Main Motor | kw | 5.5,Siemens |

Cutting Machine |

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 0.46-0.75 |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Delta |

21. | Frequency converter power | kw | 4 |

22. | Dimension Of Machine |

| About 7.5m*1.5m*1.4m |

23. | Weight | kgs | 5000 |

24. | Working area | m | 15*3 |

25. | Voltage |

| 220V,60HZ,3Phase |

Use:

Consider the construction facade as skin, so the exterior building cladding system will be the makeup and sunscreen of the facility, which the architects apply and design. Thus, the wall cladding material should be aesthetically pleasing while having functionality. It will protect the building from environmental conditions and enhance the construction’s overall appearance. The aluminum building cladding material, in particular, is arguably the most favored metal wall system which is widely used in contemporary architecture and residential buildings.

FAQ:

1. What's your warranty?

Two years, during which all parts damaged because of the quality problem will be changed for free, but not include damage caused by natural disaster or inappropriate operation or human factor.

2. What's your delivery time?

Within 60 days after receiving prepaid. Some machines are in stock, so can be delivered at any time.

3. What are your payment terms?

30% deposit is paid before production, the balance should be paid after inspection confirmation and before shipment.

4. What's your install and training?

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, a manual and video are provided to show how to install and operate.