Cladding Panel Roll Forming Machine

Cladding Roll Forming Machine can do the profile according to customer’s different requirements.

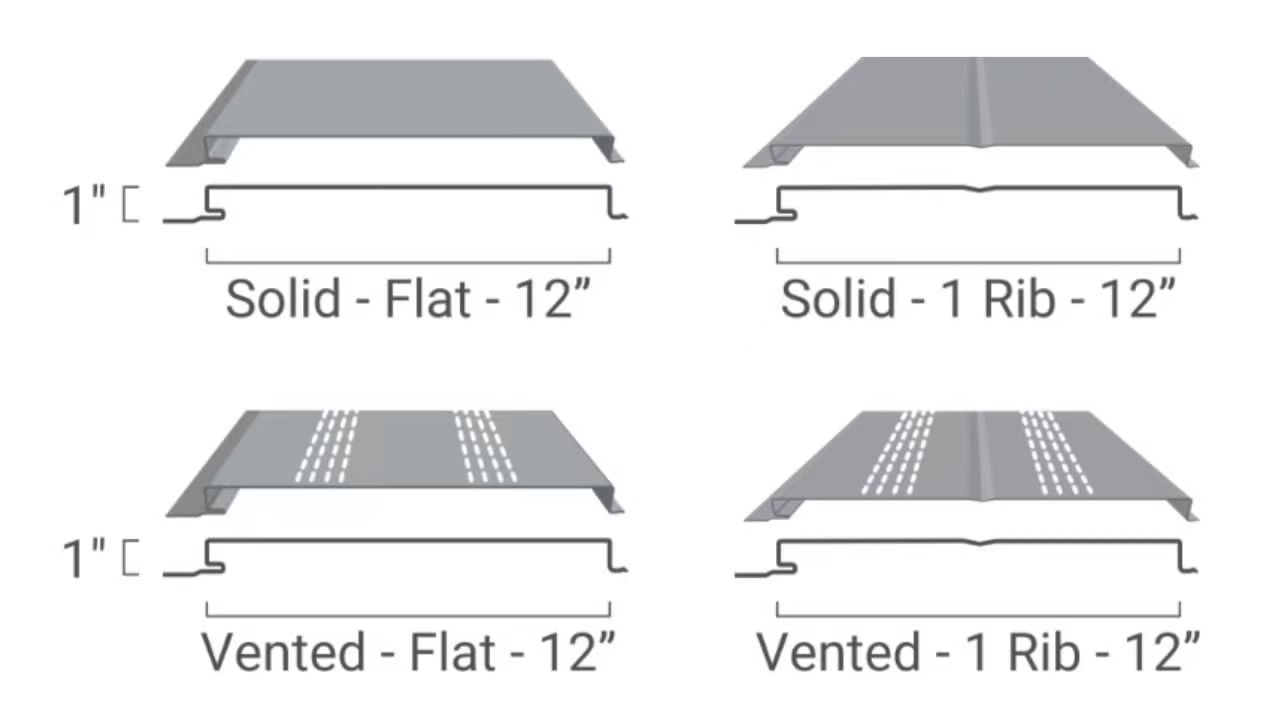

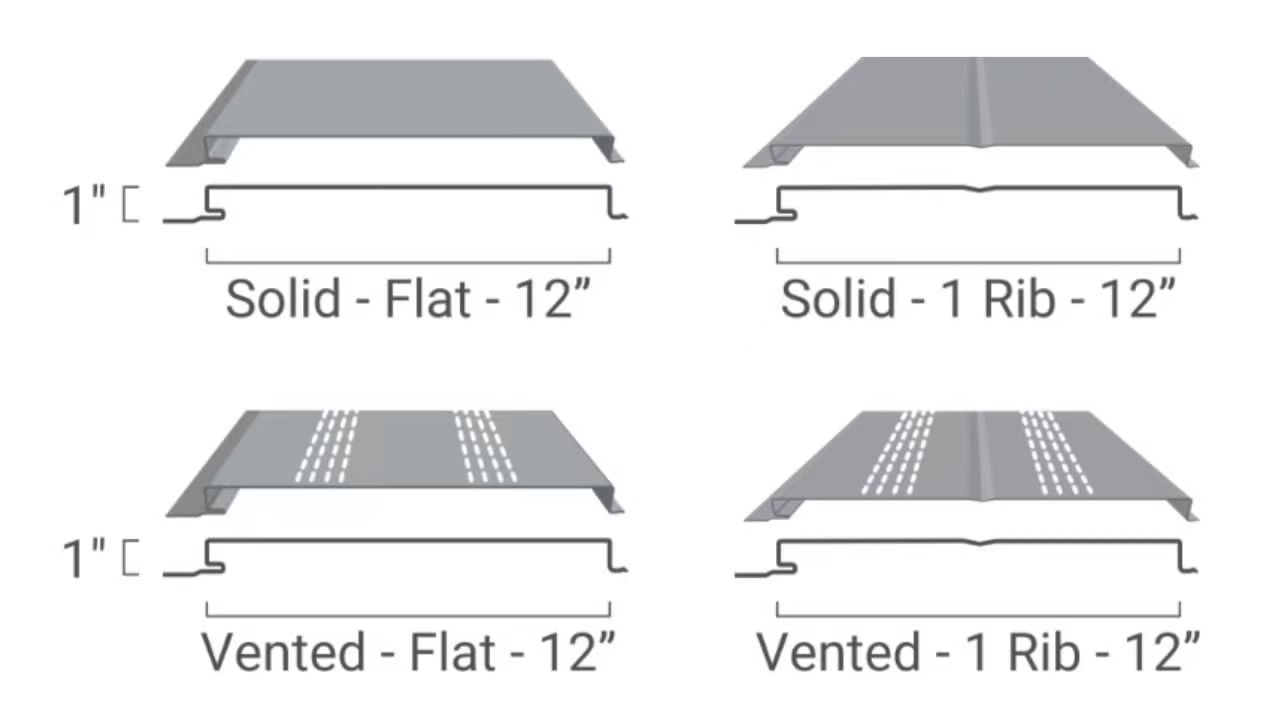

Profile drawing (can be customized)

One machine is produce different width through adjust spaces of machine:

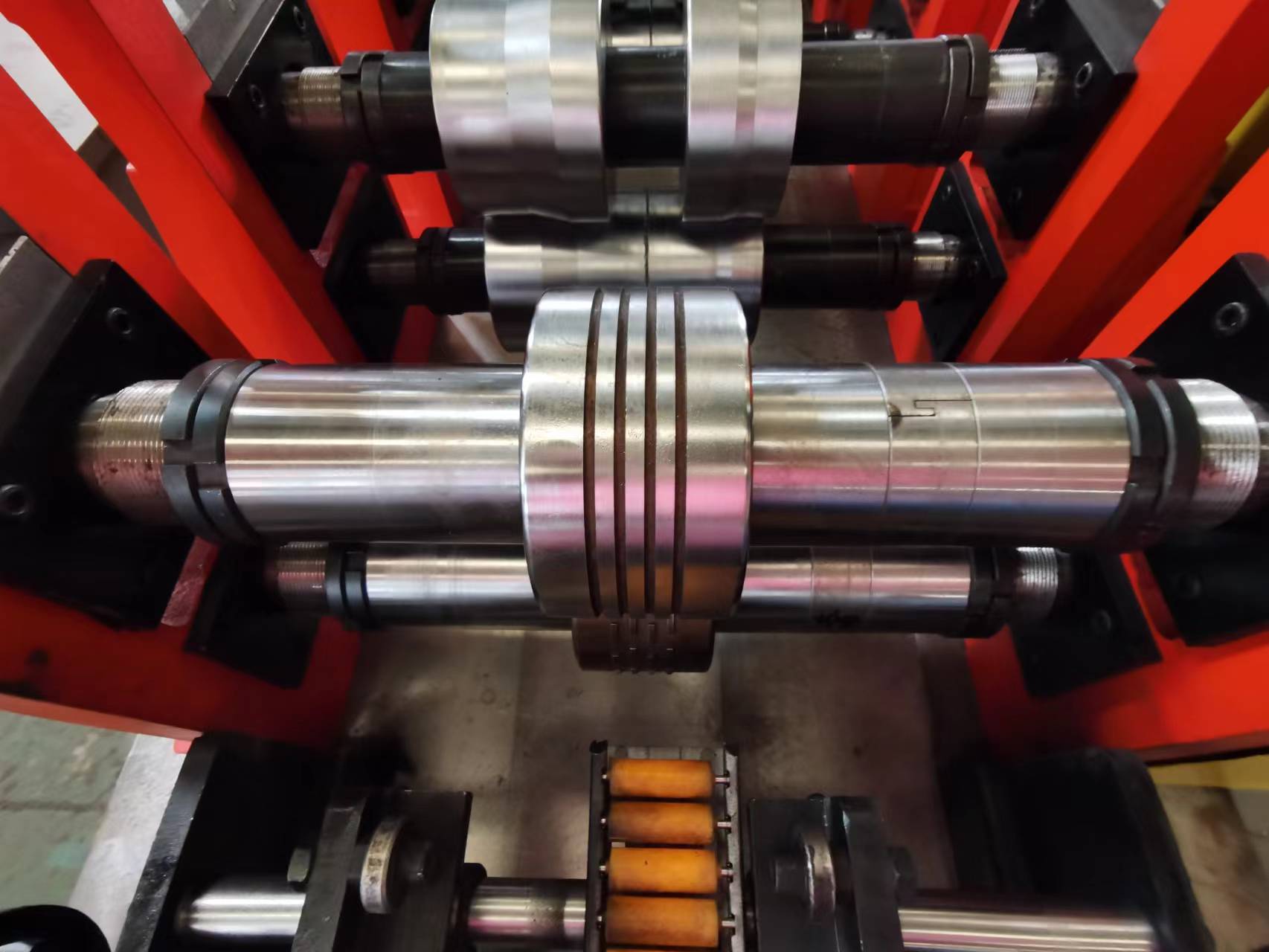

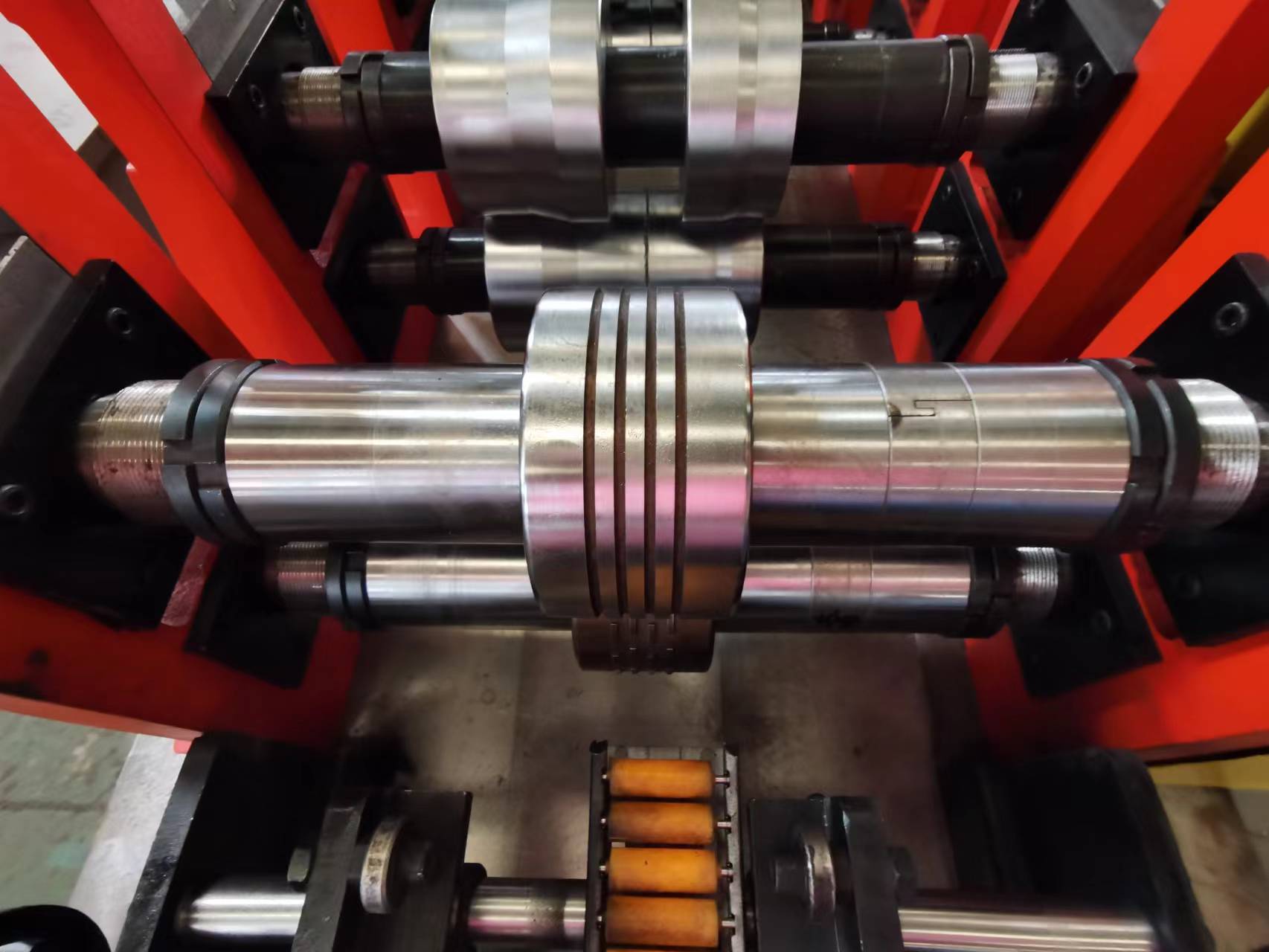

We design rolling holes on the machine:

We marked No. for each station to make after-sell service easier. When rollers need adjust, we can tell you No.5 up rollers loose and No.8 rollers tight. We have more than 12 years experience in roll forming machines, so we always pay attention to machine quality and service.

Product Advantage:

1.We use a bady casting frame for machine structure, it is does not require shearing and welding,which ensures the door panel precision when machine is working.

2.After all the rollers and shafts are finished by CNC lathes, they are hardened and tempered, then CNC lathes are finished again, and then they are precision processed with grinders, and finally they are chrome plated.Rollers and shafts processed by these processes can be more precisely roll former gauge steel.

3.We are free to choose the machine style. If your factory space is limited, you can choose our built-in machine, PLC, oil pump, motor, all built into the machine frame, saving space and beautiful.

4.The making machine is equipped with servo tracking for punching and cutting, which not only meets the customer's customization needs, but also meets the customer's high efficiency needs.

5.We can provide you with a complete set of electric decoiler, inkjet printers and packing machine in one stop,and we can delivery all by one container.

Specification:

. | Item | Unit |

|

| Cladding Roll Forming Machine |

1. | Material Of Processing |

| PPGI,Galvanized steel |

2. | Profile Type | mm | As your design |

3. | Feed coil Thickness | mm | 0.51 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 50 |

7. | Roll Station | No. | 17 |

8. | Rolling material |

| 45#steel |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed |

| 10-15m/min |

11. | Drive Type of Roll Forming Machine |

| Chain |

12. | Power of Main Motor | kw | 5.5,Siemens |

Cutting Machine |

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 0.51 |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Delta |

21. | Frequency converter power | kw | 5.5 |

22. | Dimension Of Machine |

| About 9m*1.2m*1.4m |

23. | Weight | kgs | 5000 |

24. | Working area | m | 15*3 |

25. | Voltage |

| 220V,60HZ,3Phase |

Use:

The purpose of cladding is to protect a building's structure from natural elements like wind and rain. Still, it can have other benefits, such as insulation and noise control, and it can boost the aesthetic appeal of a building.