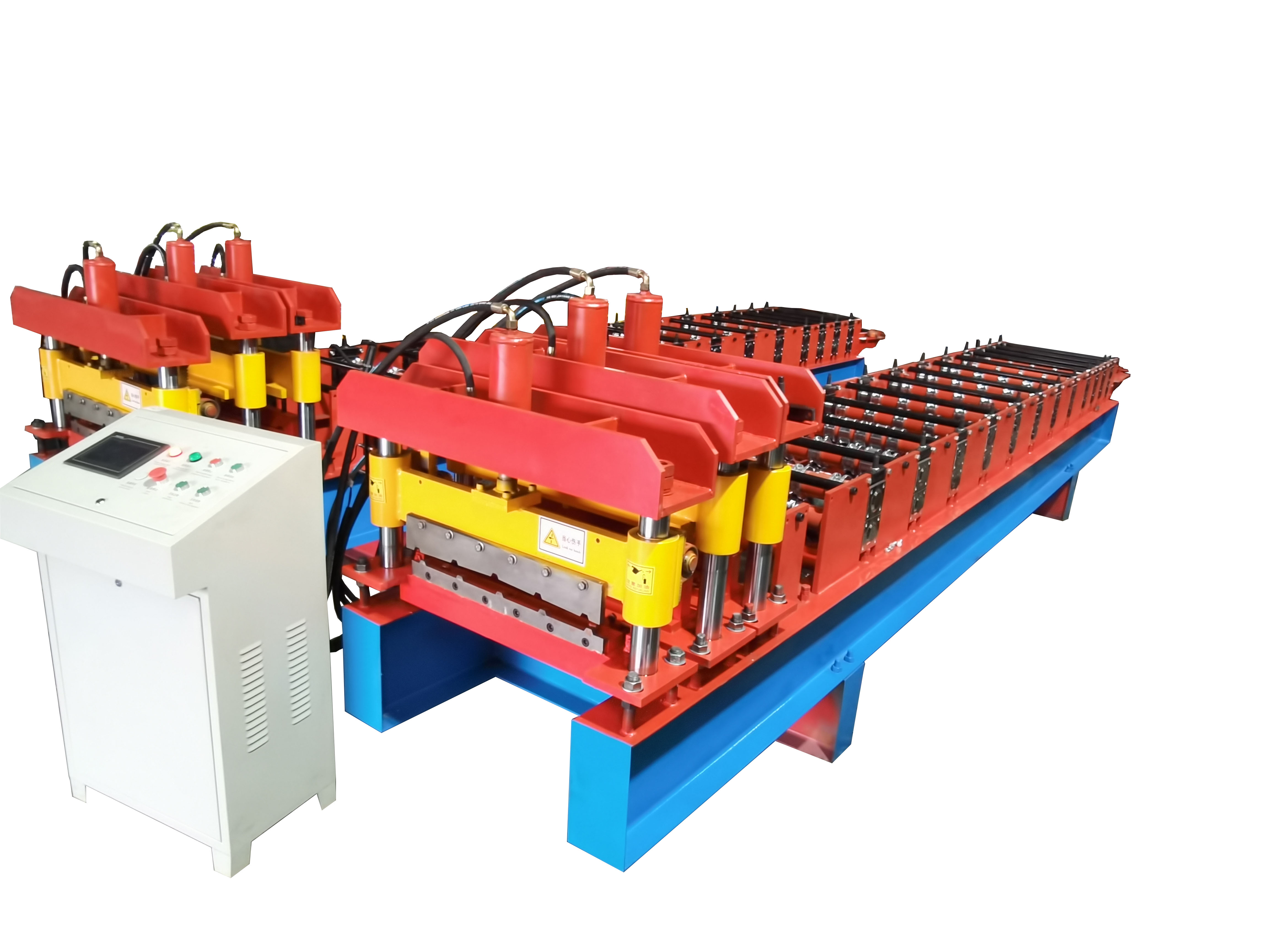

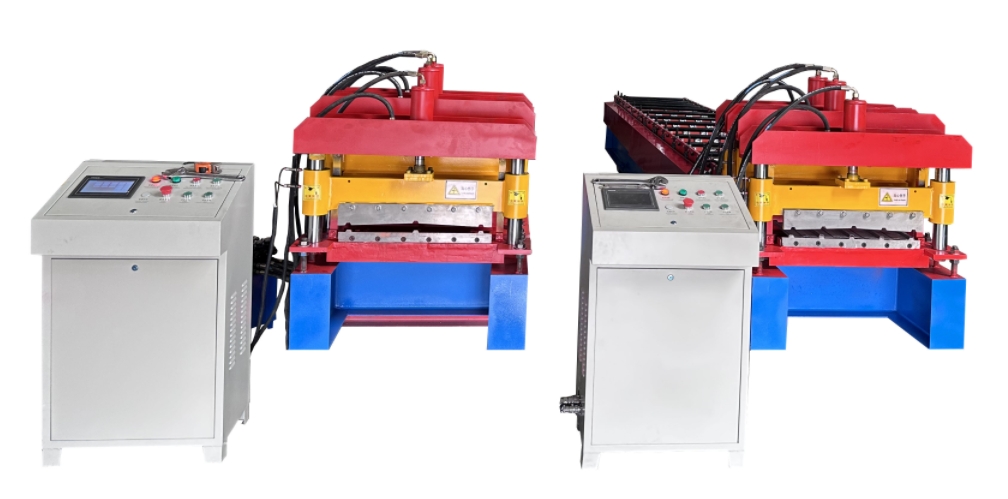

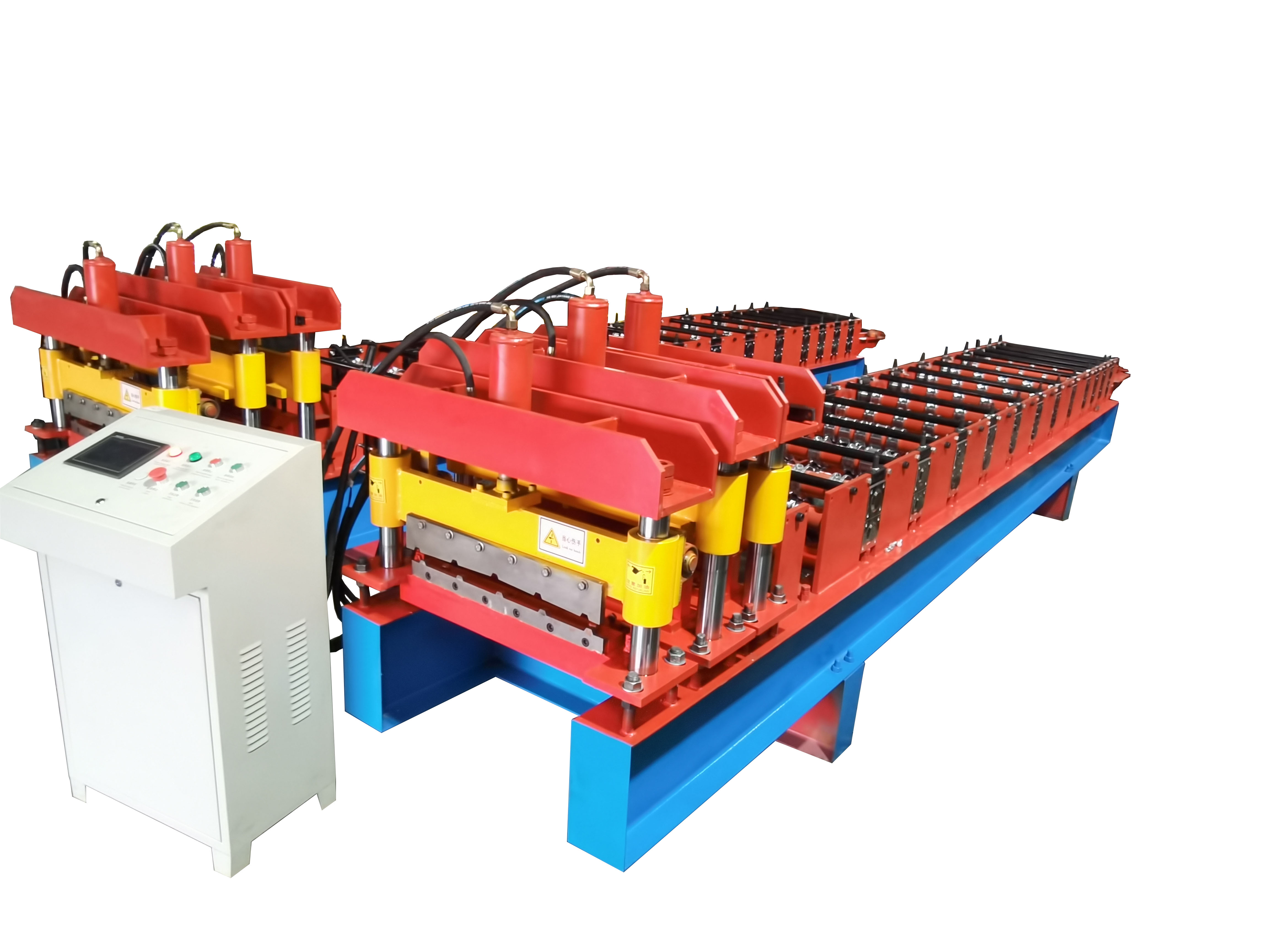

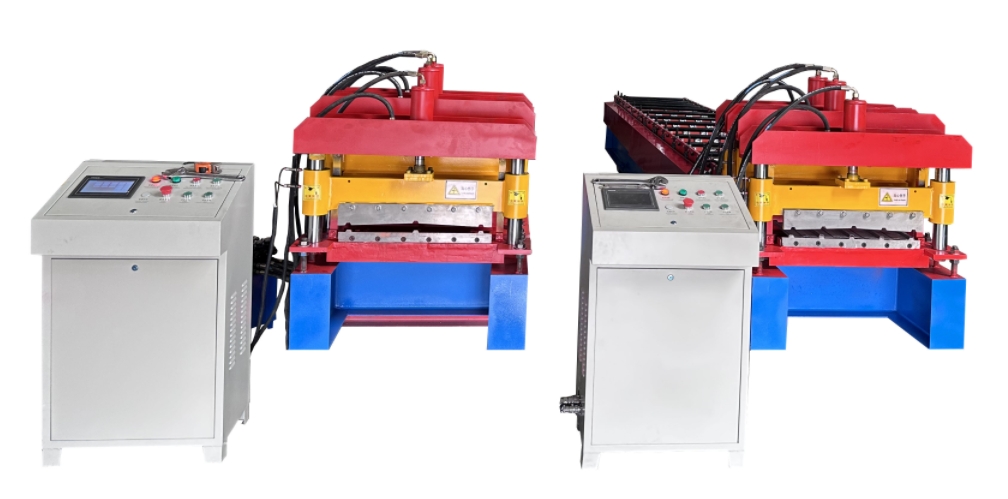

PPGI Self Lock Cladding Metal Wall Panel Roll Forming Machine

Wall Panel Roll Forming Machine can do the profile according to customer’s different requirements. This machine is include hydraulic punching hole system.

Working Flow:

Decoiler---Feeder---Roll forming Machine---Hydraulic punching holes---Hydraulic cutting system---Run out table

High Precision Roll Forming Unit:

1. Machine frame adopts welding structure with blasting treatment.

2. The roller of this line is made of No.45 steel, surface painted with hard chrome, all treated by full CNC precision machines, therefore the roller has good rigidity.

Specfication Of Wall Panel Roll Forming Machine:

No. | Item | Unit |

|

| 0.3-0.6mm Wall Panel Roll Forming Machine |

1. | Material Of Processing |

| PPGI,GI |

2. | Profile Type |

| As customer’s request |

3. | Feed coil Thickness | mm | 0.3-0.6 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 70 |

7. | Roll Station | No. | 14 |

8. | Rolling material |

| 45#steel |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed | m/min | 15-20 |

11. | Drive Type of Roll Forming Machine |

| Chain 1 inch |

12. | Power of Main Motor | kw | 5.5 |

Cutting Machine |

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 0.3-0.6 |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

19. | Power of hydraulic | kw | 4 |

Control Unit |

20. | Type |

| PLC controlled |

21. | PLC brand |

| Delta |

22. | Dimension Of Machine | mm | 7000*1350*1400 |

23. | Weight | kgs | 3500 |

24. | Working area | m | 20*3 |

25. | Voltage |

| 380V,60HZ,3Phase |

High Quality Punching and Cutting System :

Adopts post cutting, the cutting blade material is Cr12 with quenched treatment.

Advanatges:

Our company commits to providing customized coil processing solutions according to each customer's specific metalworking process. With an experienced technical team and continuous research investment, we are capable to offer coil handling solutions that meet higher international standards.

Reliable after-sell service,we always near with our customers when they need us to offer help.

Use:

In this light, Fabtech takes the best advantage of pre-painted galvanized iron (PPGI) partition walls by using it as an innovative and eco-friendly solution.