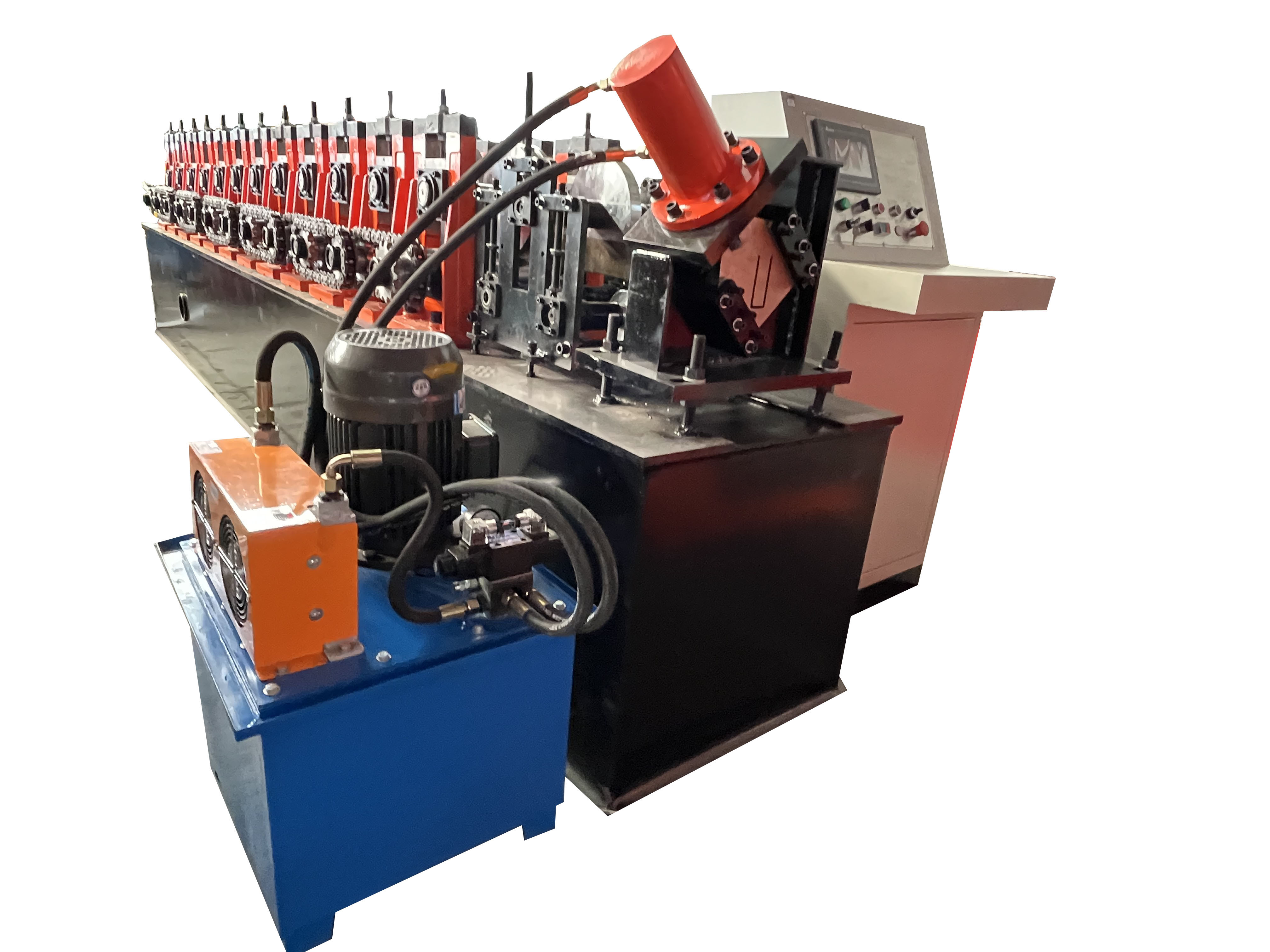

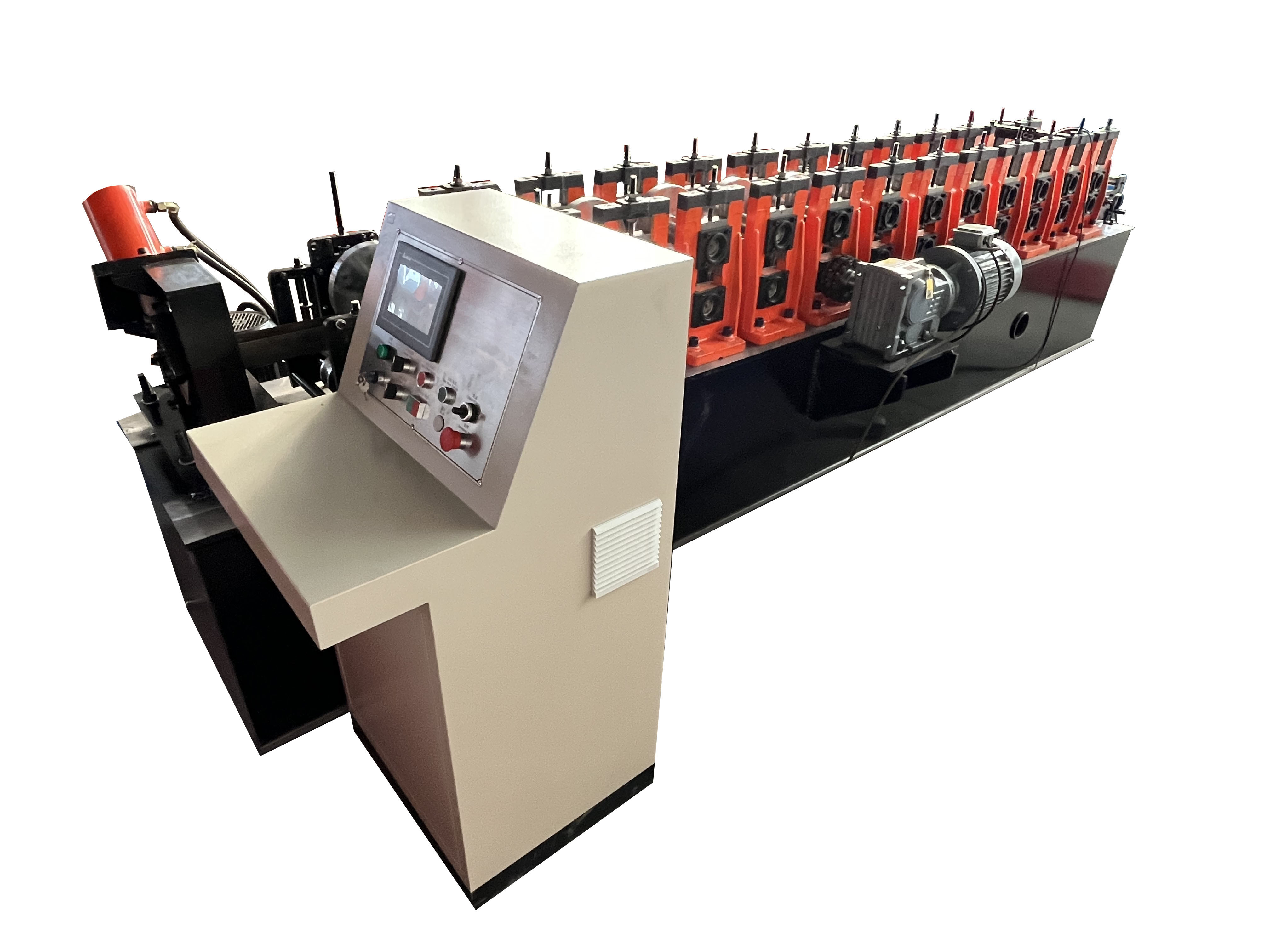

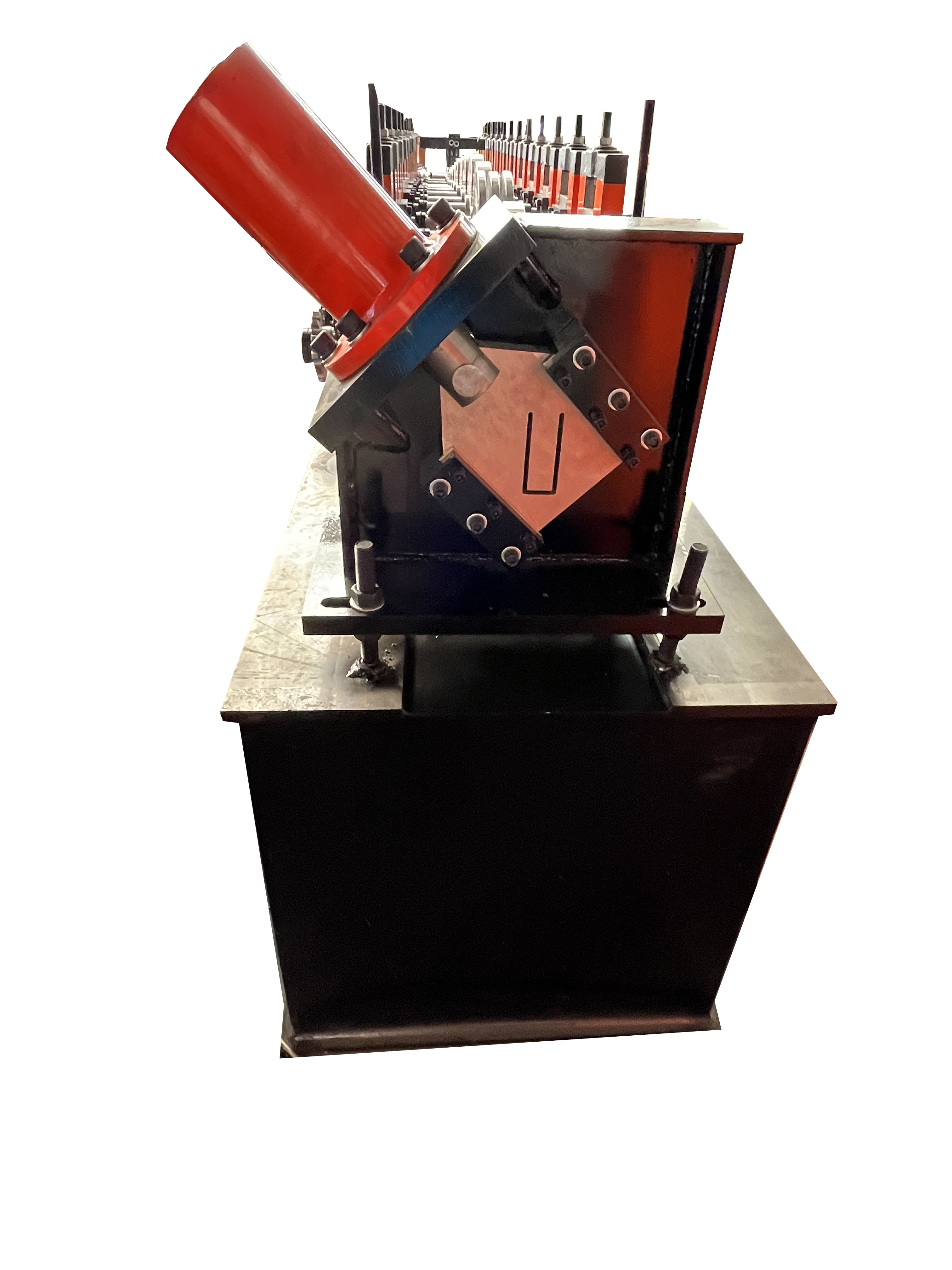

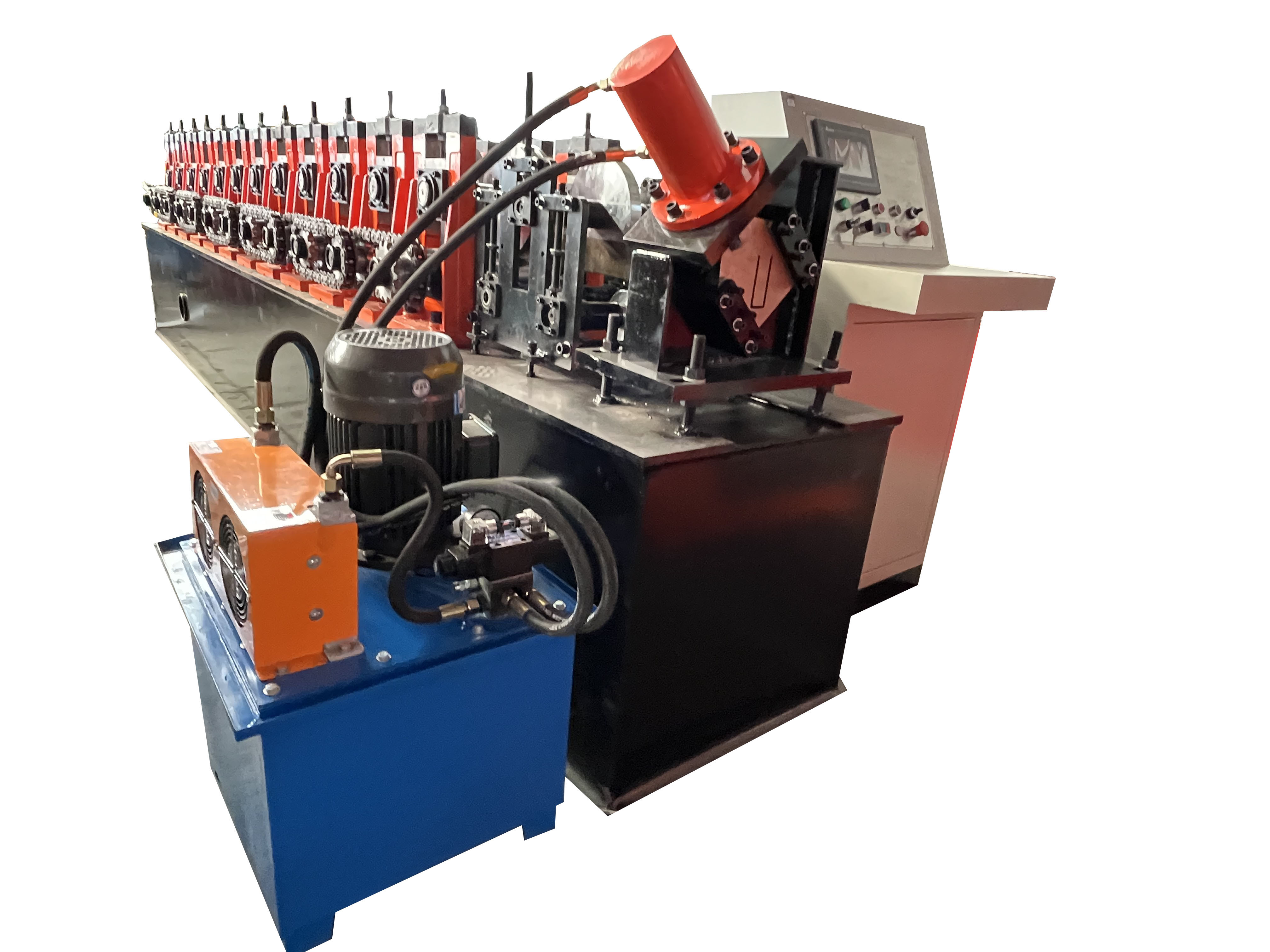

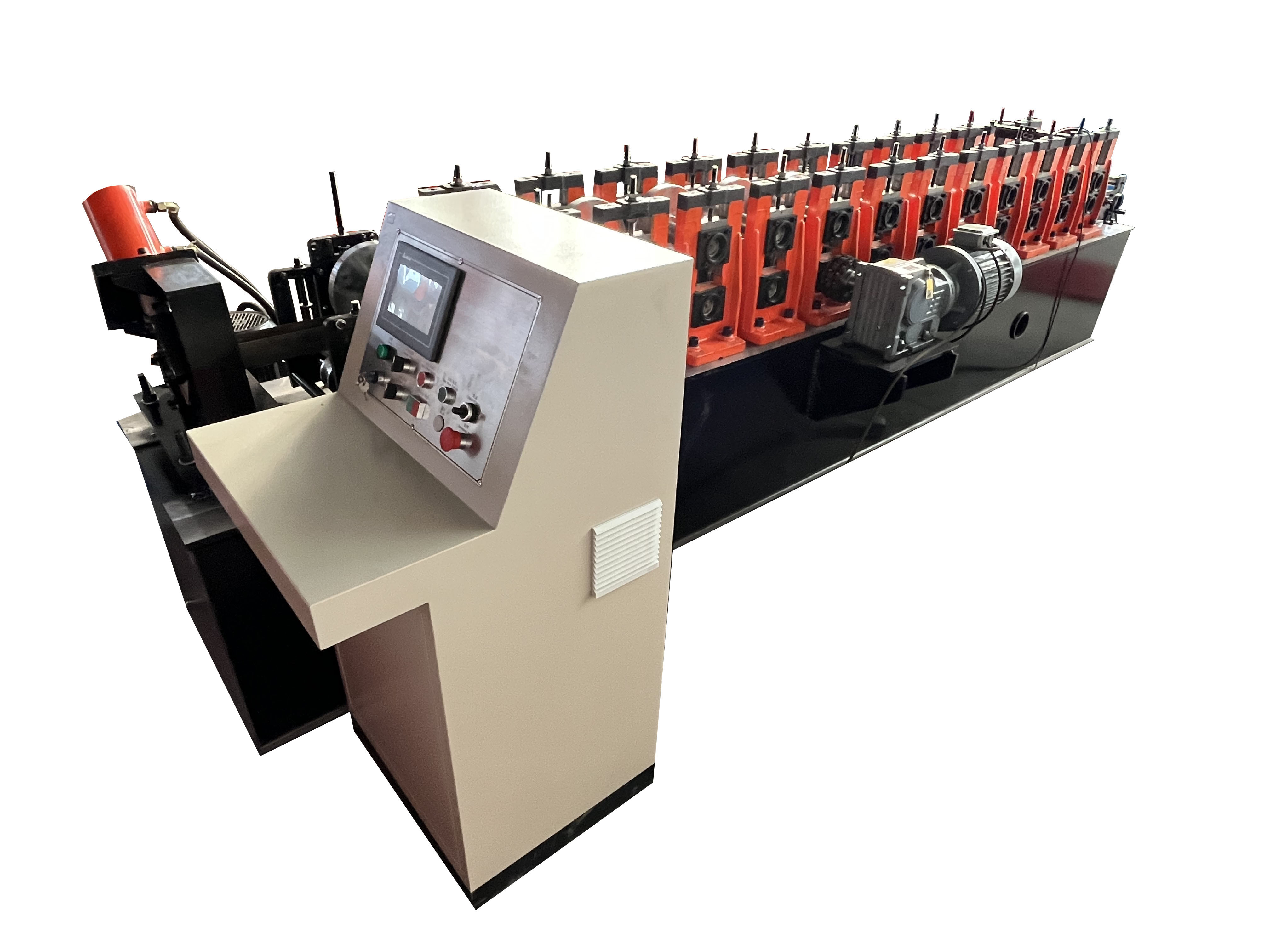

U Channel Sliding Garage Gate Guide Rail Cold Roll Forming Machine

Steel side guide rail shutter door roll forming machine with hydraulic cutting system

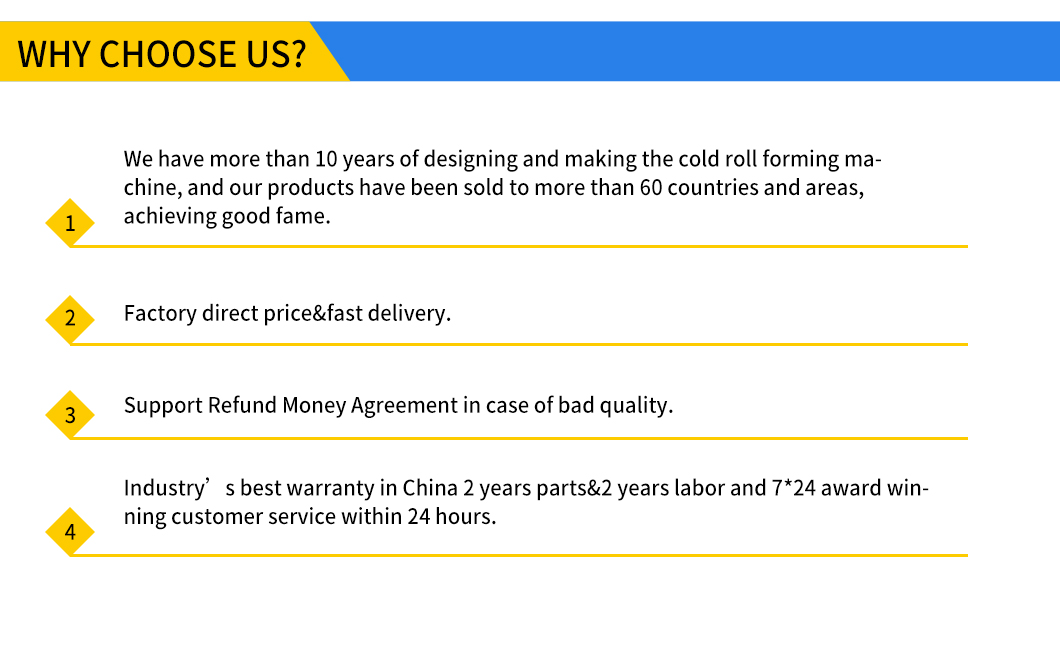

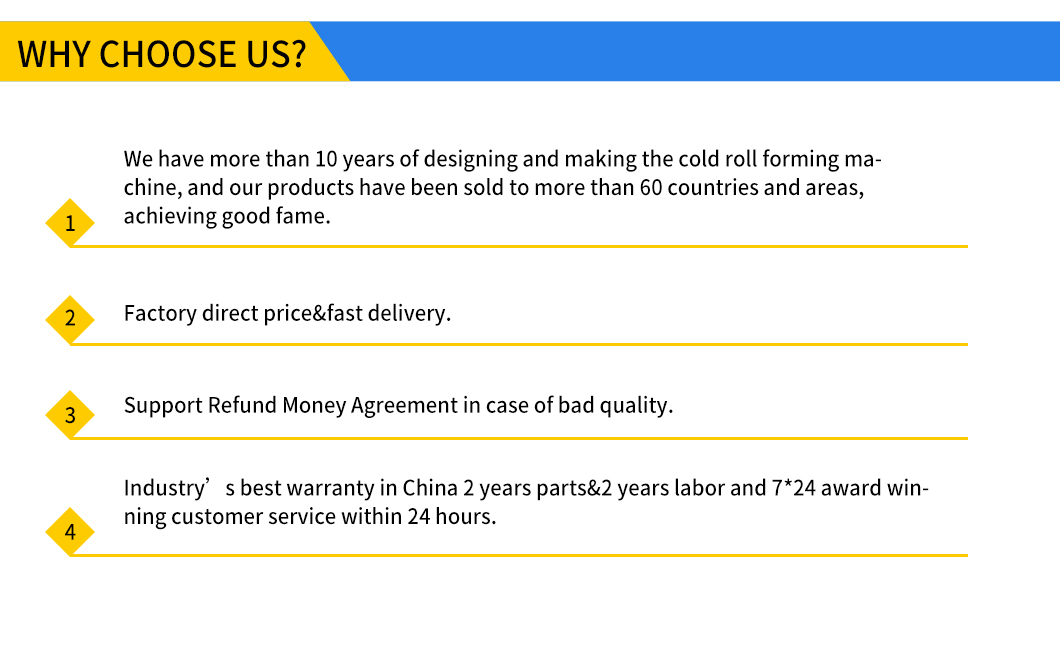

---- Good quality: We have a professional designer and experienced engineer team.And the raw material and accessories we use are good.

---- Good service: we provide the technical support for whole life of our machines.

---- Elegant apperance:Protect the machine from rust and the painted colour can be customized

---- Reasonable price:We offer the best price in our industry.

The Specification of Guide Rail Roll Forming Machine:

No. | Item | Unit |

|

| U Guide Roll Forming Machine |

1. | Material Of Processing |

| Galvanized Steel |

2. | Profile Type | mm | 50 and 40 |

3. | Feed coil Thickness | mm | 1-2 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 70 |

7. | Roll Station | No. | 10 |

8. | Rolling material |

| Gr15 |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed |

| 10-15m/min |

11. | Drive Type of Roll Forming Machine |

| Chain |

12. | Power of Main Motor | kw | 7.5 |

Cutting Machine |

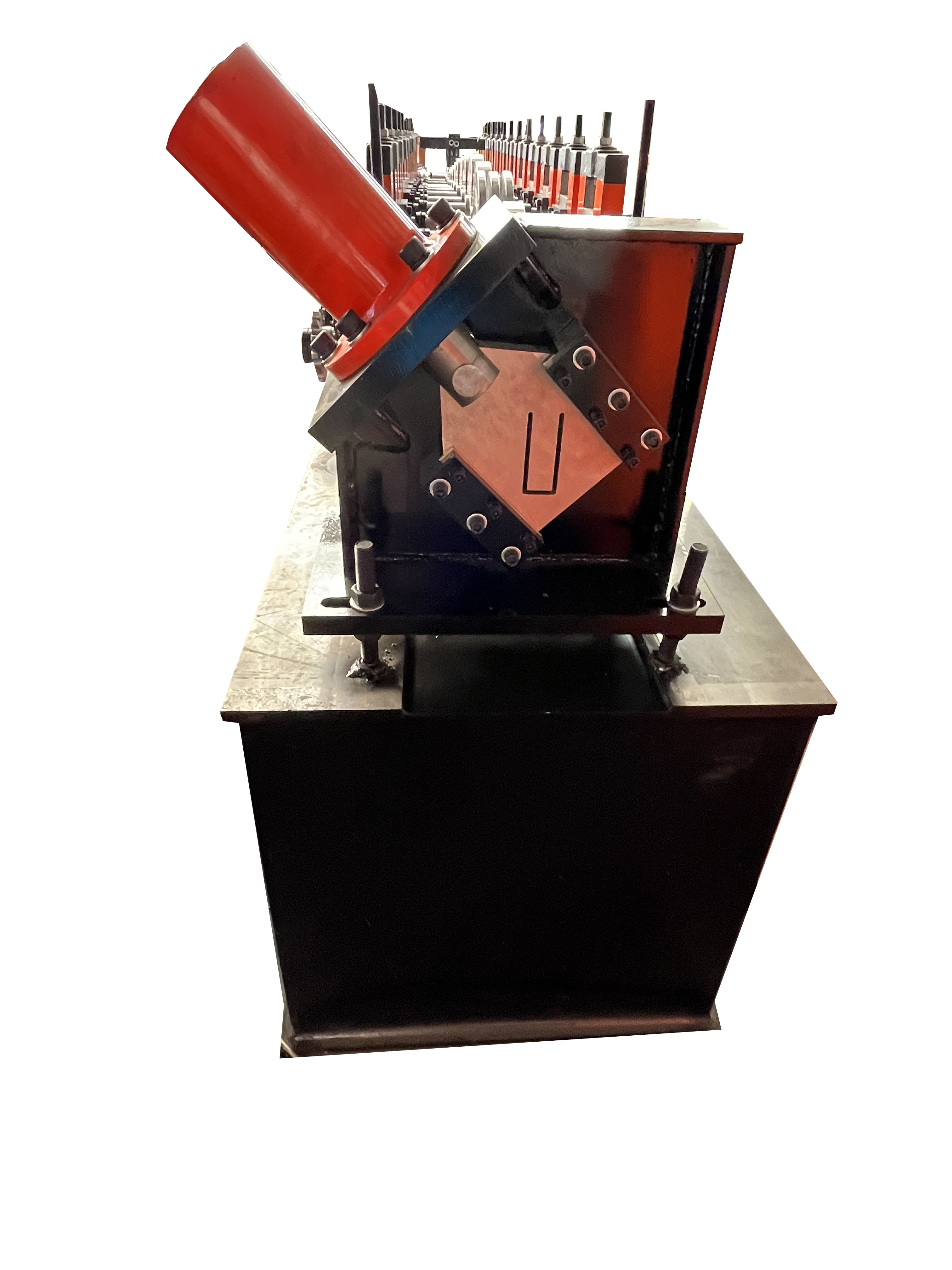

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 1-2 |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Delta |

21. | Frequency converter power | kw | 4 |

22. | Dimension Of Machine |

| About 5m*1.2m*1.4m |

23. | Weight | kgs | 3000 |

We use casting frame for machine stucture, it is without cutting and welding, then it is can make sure U guide rail forming in high precision and machine working in stable.

Feeder system add hanel wheel, it is easy to adjust coil position to feeder.

Hydraulic cutting is high speed working,and cutting rail is well, no burr, cutting blade use SK-II material with hard treatment, it is can keep long-time working life.

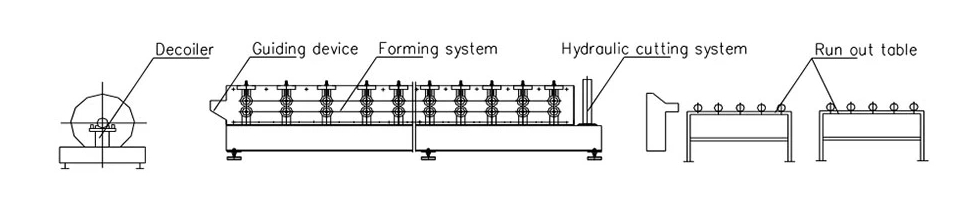

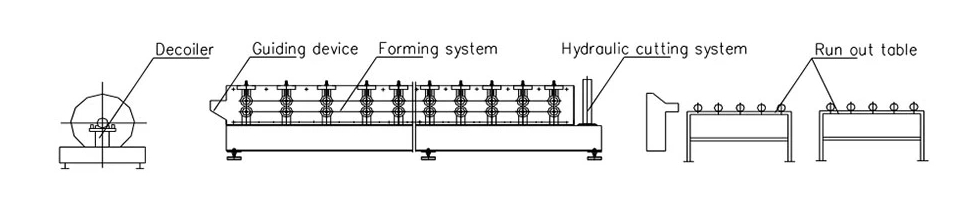

Working Flow:

Decoiler---Feeder---Roll Forming Machine---Hydraulic Cutting---Run Out Table

This is very simple machine, setting up orders in PLC,and only need one worker to operating it.