Roller Shutter Door Guide Rail Roll Forming Machine

Zunsheng rolling shutter door track door rail roll forming machine is designed to produce the shutter door rails in batch fully automatically.

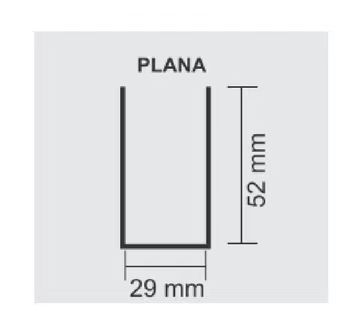

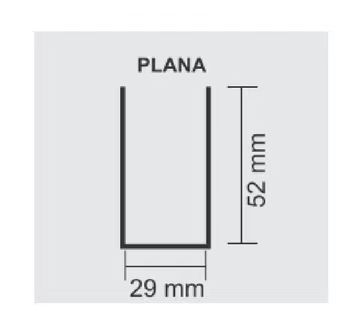

For the door track and door rails, in the market, there are many types, here I will introduce one special one with the anti-noise function.

Rolling shutter door track or guide rails are usually made out of galvanized steel or cold rolled steel strips with thickness 1.2-2mm and

whenever there is a roller shutter door or a sliding door installed, there will be the door track or guide rails.

Detail of Guide Rail Roll Forming Machine:

Specification:

No. | Item | Unit |

|

| High Speed C Channel Roll Forming Machine |

1. | Material Of Processing |

| Galvanized Steel |

2. | Feed coil Thickness | mm | 1.5-2.0 |

3. | Y.S | M pa | 300 - 650 |

4. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

5. | Shaft Diameter | mm | 60 |

6. | Roll Station | No. | 10 |

7. | Rolling material |

| Cr12 |

8. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

9. | Line Speed | m/min | 10-30 |

10. | Drive Type of Roll Forming Machine |

| Chain |

11. | Power of Main Motor | kw | 7.5+2.3 |

Cutting Machine |

12. | Type |

| PLC controlled Hydraulic Cutting |

13. | Thickness capacity | mm | 1.5-2.0 |

14. | Width capacity | mm | As drawing |

15. | Cutting blade steel grade |

| Cr12, quenching |

16. | Hardness |

| 58-62 HRC |

17. | Cutting tolerance | mm | +/- 1 |

18. | Cutting blade number | Pieces | 2 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Xinjie |

21. | Hydraulic system power | kw | 5.5 |

22. | Dimension Of Machine |

| About 5.5m*0.8m*1.4m |

23. | Weight | kgs | 3200 |

24. | Working area | m | 12-3 |

25. | Voltage |

| 220V,60HZ,3Phase |

Features and Advantages of Garage Door Guide Rail Roll Forming Machine

Garage Door Roll Forming Machine, specially designed for forming rolling shutter door panel, under mass-production.

Production speed: 20/30/40 m/min optional.

Working with non-stop flying cut and full automatically stacking system, Max speed of the line can reach 40 m/min.

Cassette type platform quick change Machine base for multi-profile purposes is available for choice.

Most of hot & popular profiles models, we have ready machines in stock for prompt delivery.