Solar Panel Roll Forming Machine

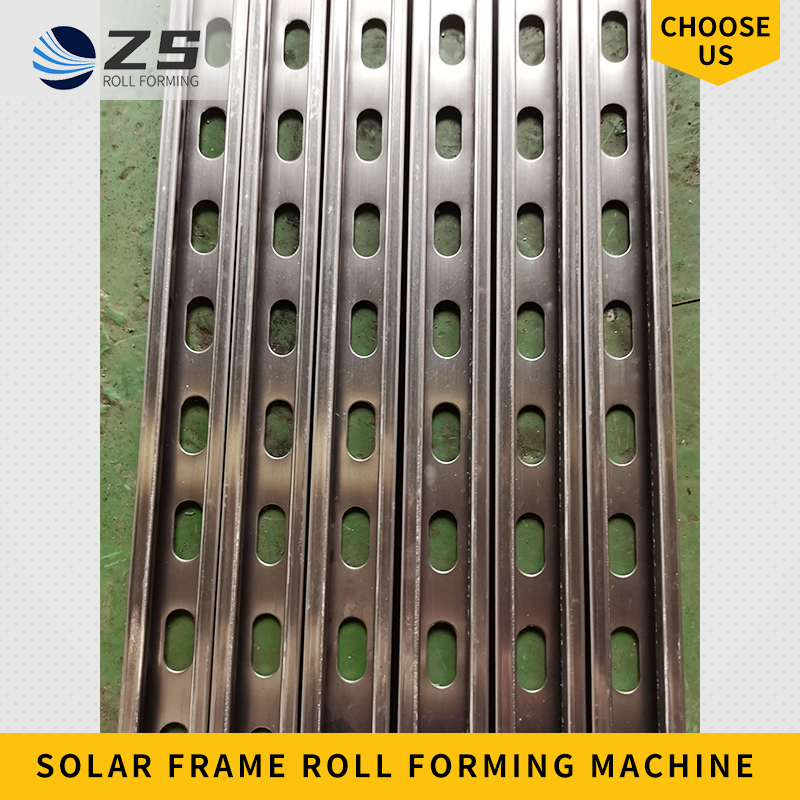

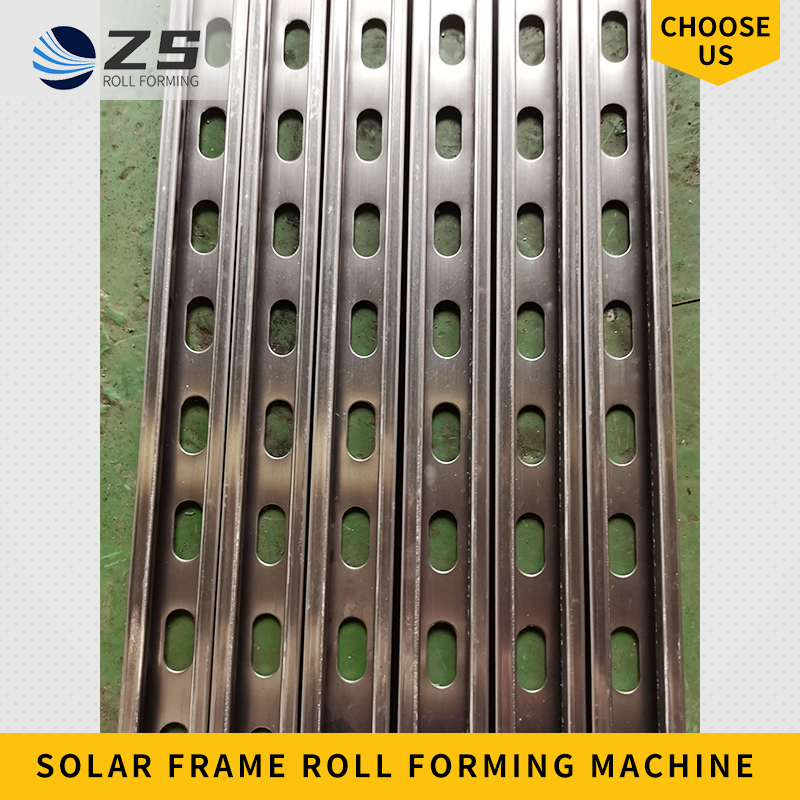

PV support bracket made by Zunsheng Roll Forming Machine is a solar mounting support cold roll formed steel Channel that used as solar

panel support or constructions for structural purpose. The channel is formed from metal coil strips, and then roll formed by struct channel

roll forming machine into an open channel section with lips to provide additional stiffness.

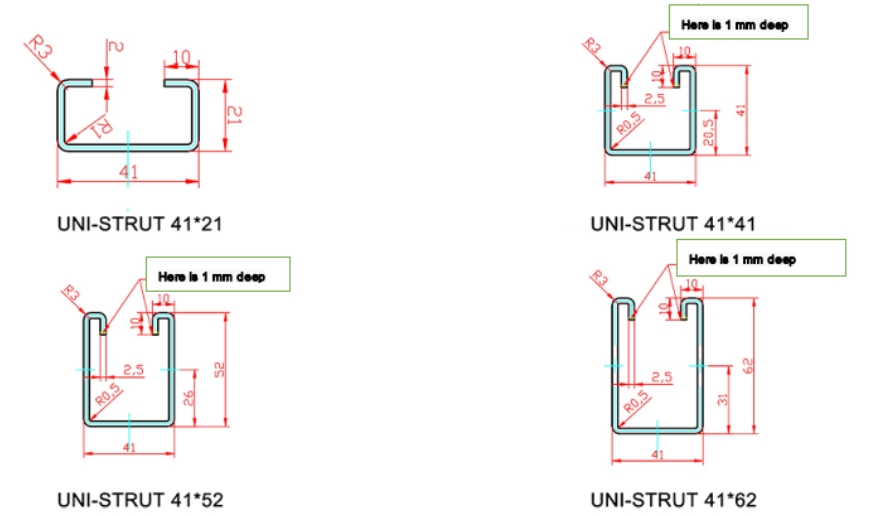

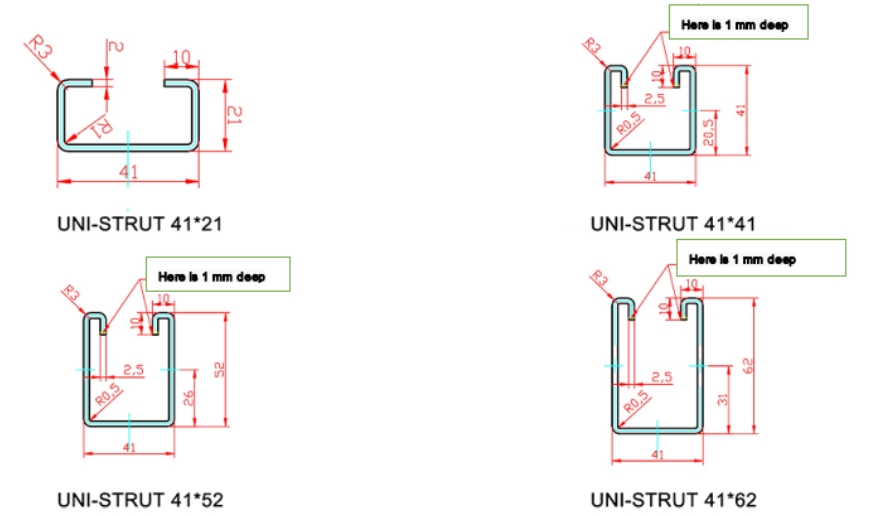

Zunsheng solar mounting support panel Channel Machine is to form 1.5mm-2.5mm strut channels with required types.The

machine is able to produce 2 or 3 or more types of strut channel by adjust the roll forming mould. The standard strut channel sizes are: 41*41, 41*21, and also some customized shapes.

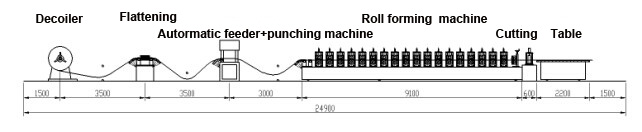

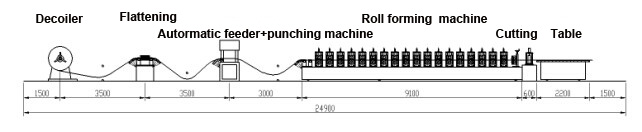

Working Flow:

Electrical Decoiler---Automatic Entry Beach---Punching Machine-----Roll Forming Machine--- Automatic Shearing Mechanism---

Computer Control Cabinet---Run-out Tables

Specification:

| No. | Main Parameters | Roll Forming Mill Parameters |

| 1. | Effective Width | 41mm | Forming Stations | 22-step |

| 2. | Effective Width Tolerance | ±0.5mm | Base | H450 |

| 3. | Material Thickness | 2.0-2.5mm | Side Wall Thickness | Q235 t18mm/ Casting Frame |

| 4. | Inspection Thickness

| 2.0mm | Shaft Diameter | φ75/85mm

|

| 5. | Application Material | Galvanized Sheet(GI)

Cold Roll Steel(CRC) | Main Motor Power | 15 KW |

| 6. | Yield Strength | Q235-Q550Mpa | Screw Bolts | Grade 8.8 |

| 7. | Product Speed | 12-18m/min | Tie Rod | ф22 Galvanized |

| 8. | Effective Size | As Customer Design | Roller | GCr15(=EN31 steel), precision machined, hard Chrome Coated |

| 9. | Control System | PLC Control System | Processing Mode | CNC lathes, Hear Treatment, hard Chrome Coated, with thickness 0.04mm |

| 10. | Testing Material | Zunsheng Will Provide The Size of Feeding Material to Purchase That 2 Weeks Before Machine Testing |

All parts For This Line:

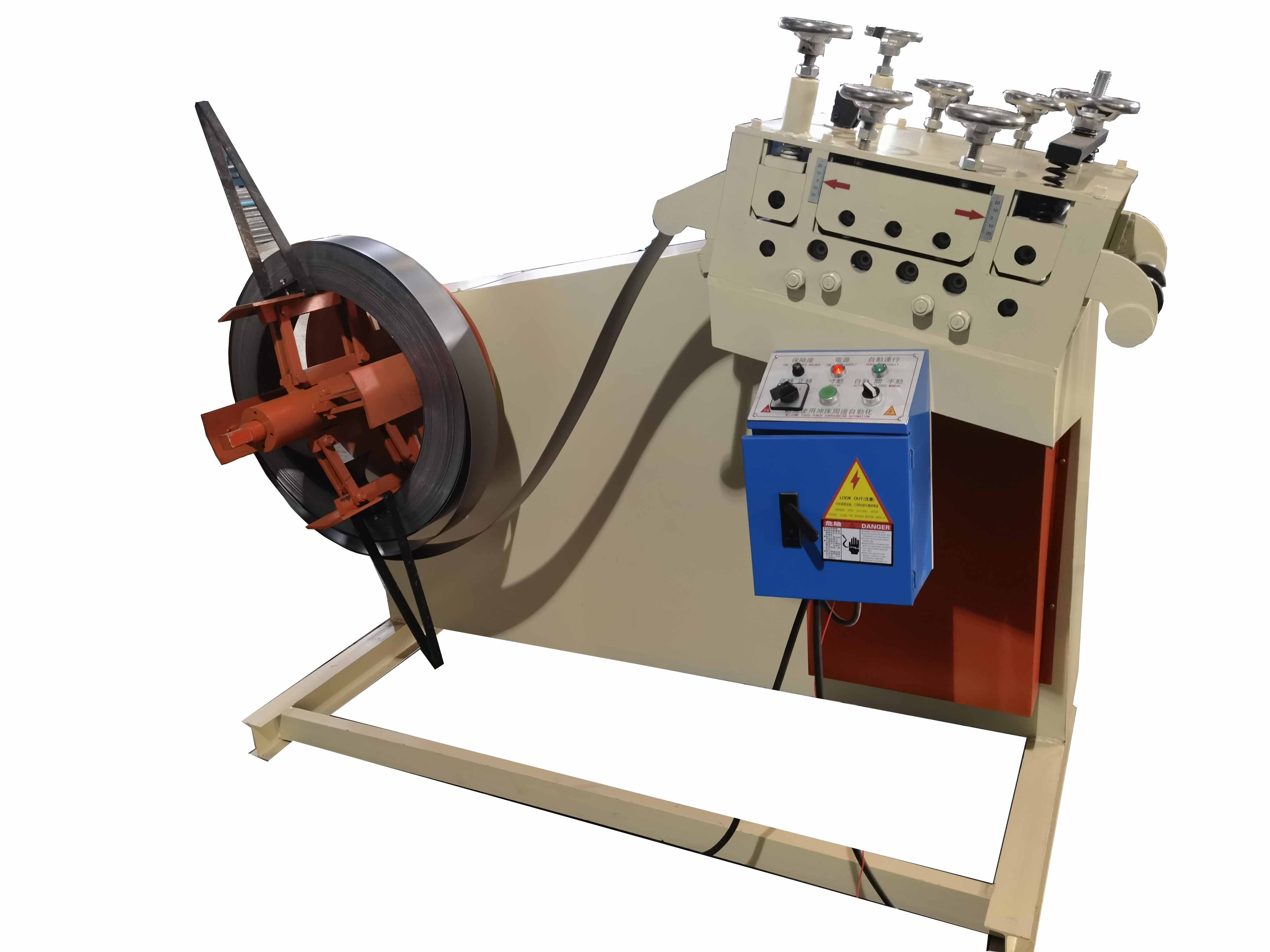

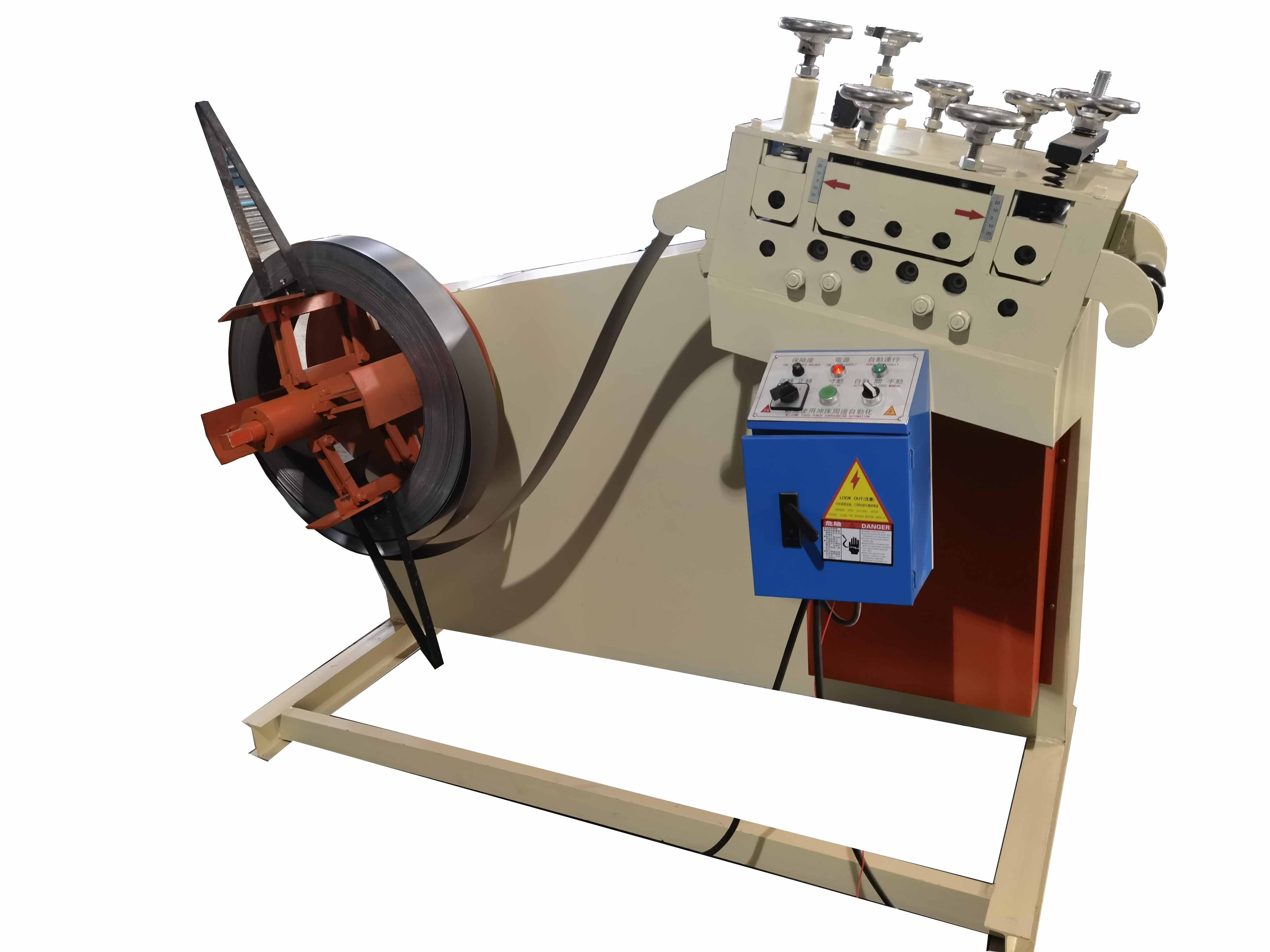

3T Electrical Decoiler With Flattening:

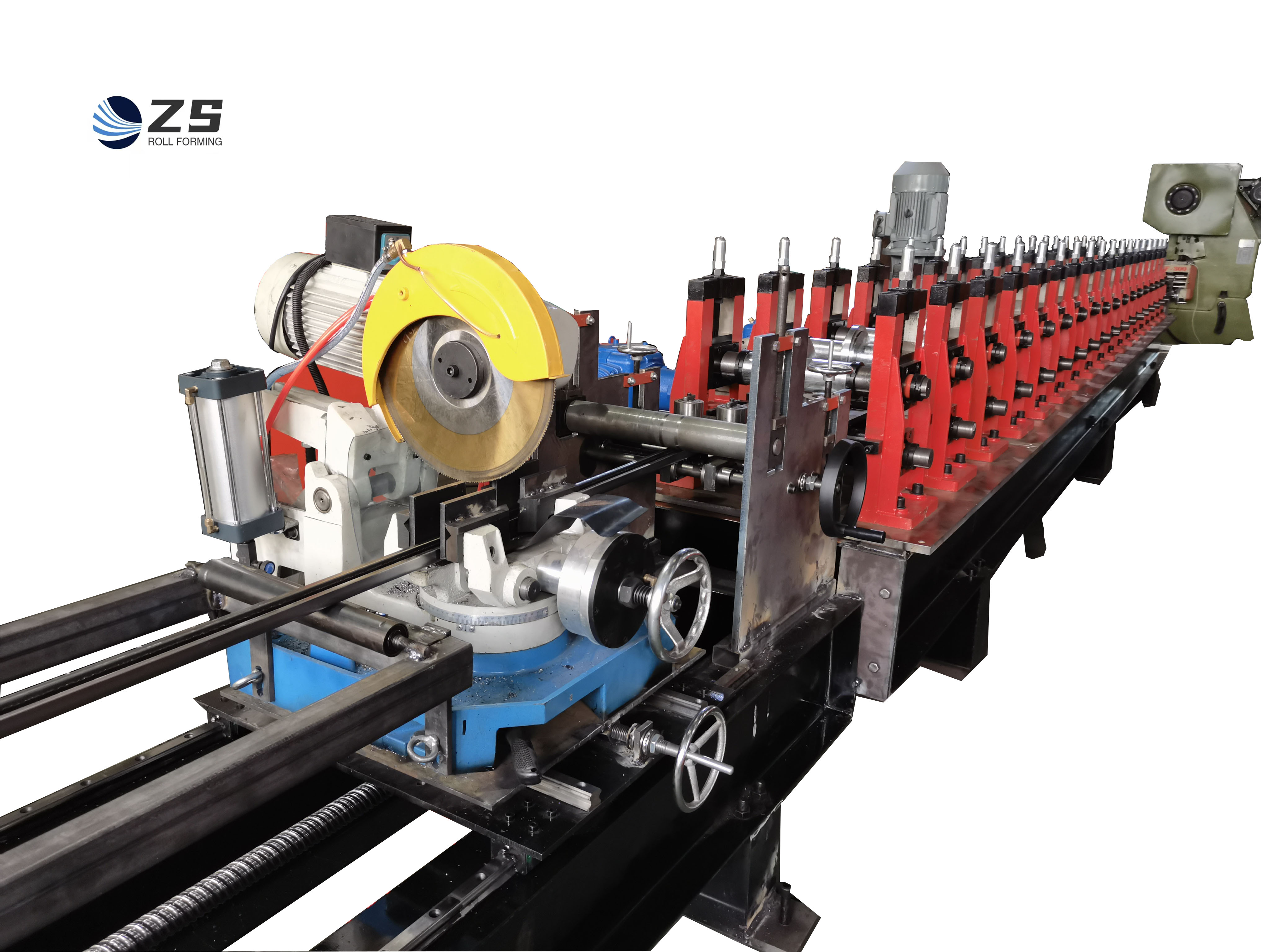

Punching Machine With Servo Motor:

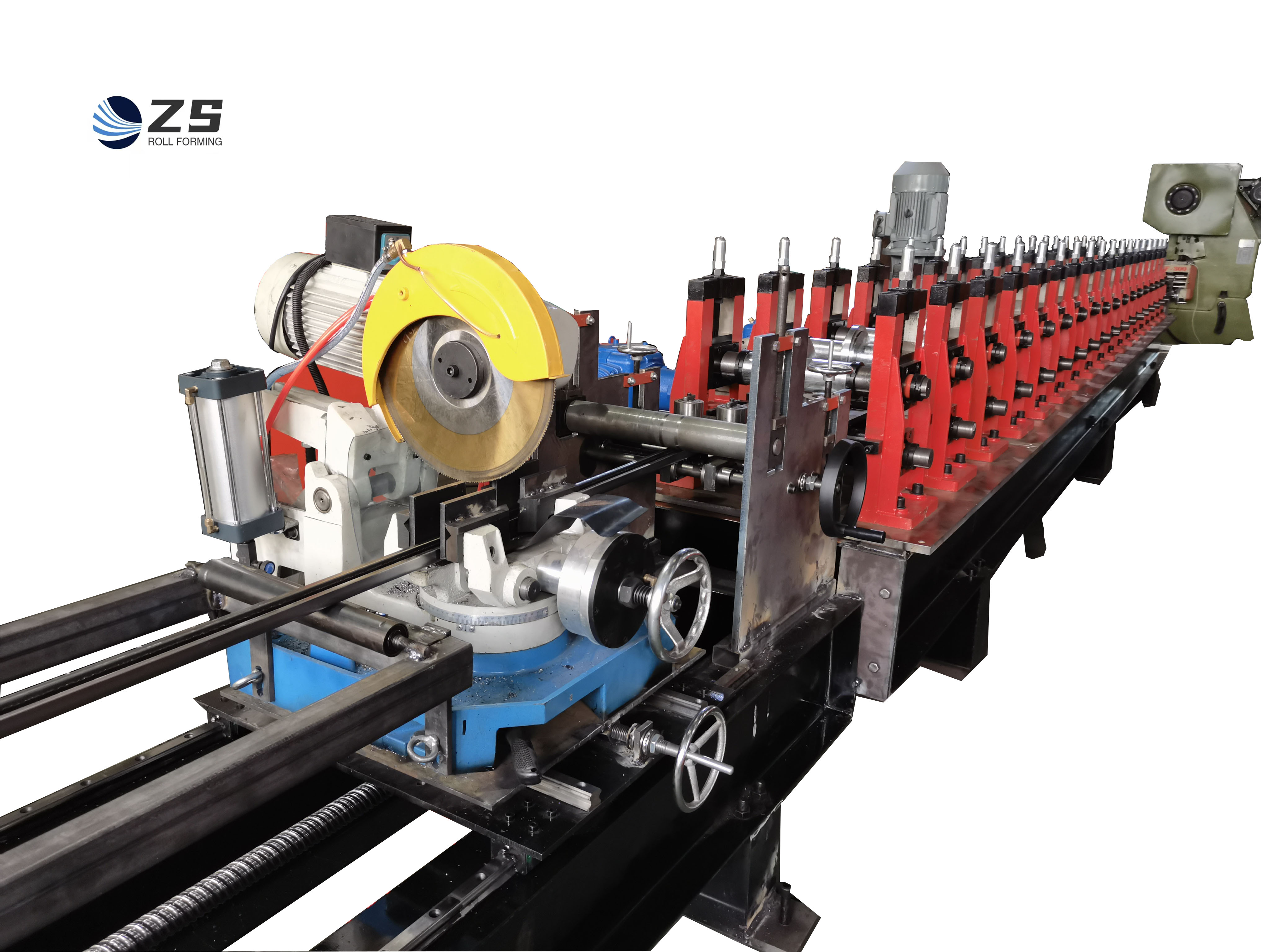

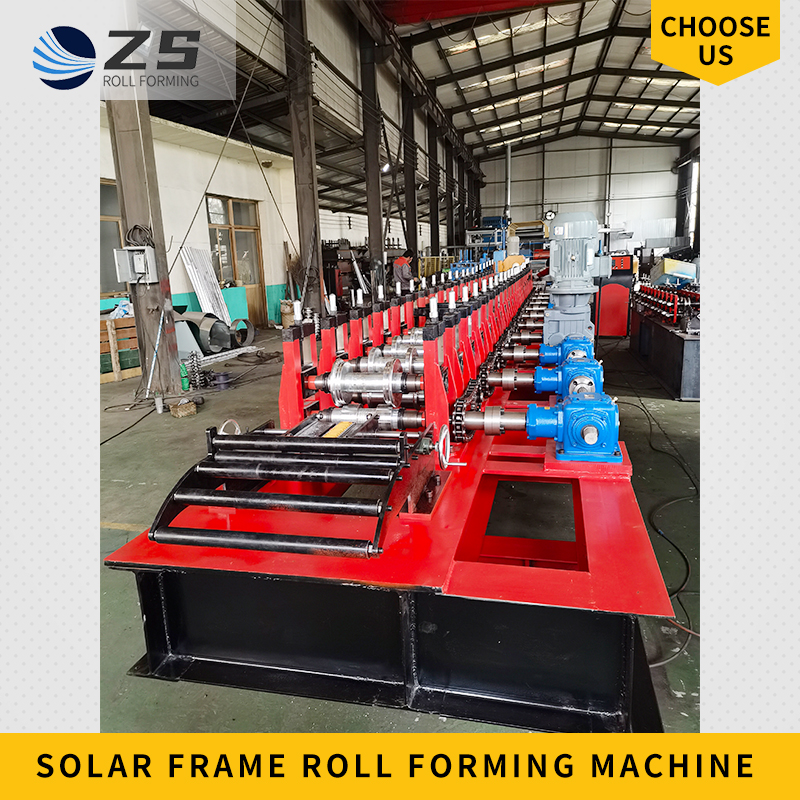

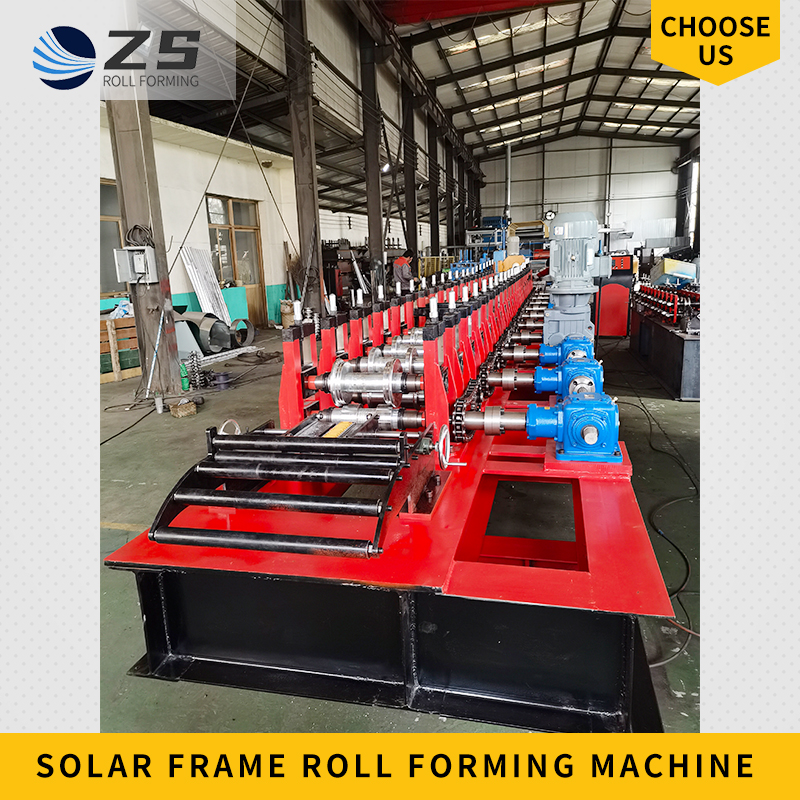

Main Roll Forming Machine:

Product Use:

Solar Mounting Structures are critical components that ensure the efficiency of a solar power system in both utility and rooftop applications. These frameworks allow panels to rest comfortably at the right angle which helps in maximizing energy generation.

Advantage:

1.We use a bady casting frame for machine structure, it is does not require shearing and welding,which ensures the solar panel frame precision when machine is working.

2.After all the rollers and shafts are finished by CNC lathes, they are hardened and tempered, then CNC lathes are finished again, and then they are precision processed with grinders, and finally they are chrome plated.Rollers and shafts processed by these processes can be more precisely roll former gauge steel.

3.We are free to choose the machine style. If your factory space is limited, you can choose our built-in machine, PLC, oil pump, motor, all built into the machine frame, saving space and beautiful.

4.The making machine is equipped with servo tracking for punching and cutting, which not only meets the customer's customization needs, but also meets the customer's high efficiency needs.

5.We can provide you with a complete set of electric decoiler, inkjet printers and packing machine in one stop,and we can delivery all by one container.