Low Cost PV Support Mounting Steel Structure Metal Rack Solar Panel Frame Machine

Material:

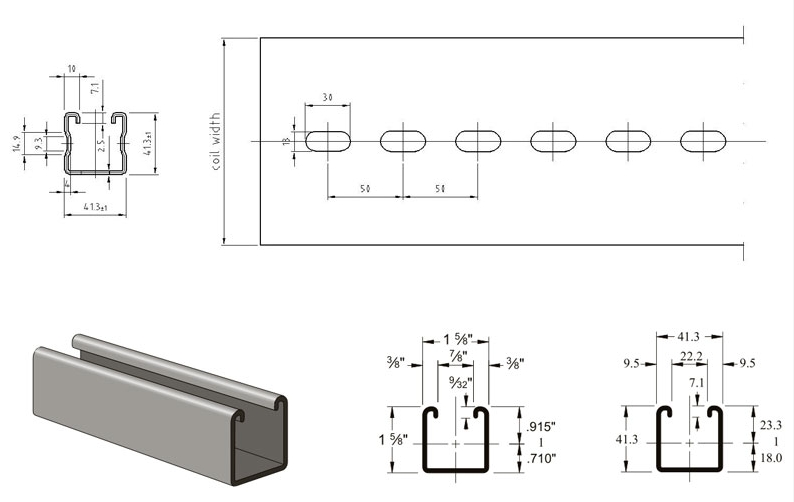

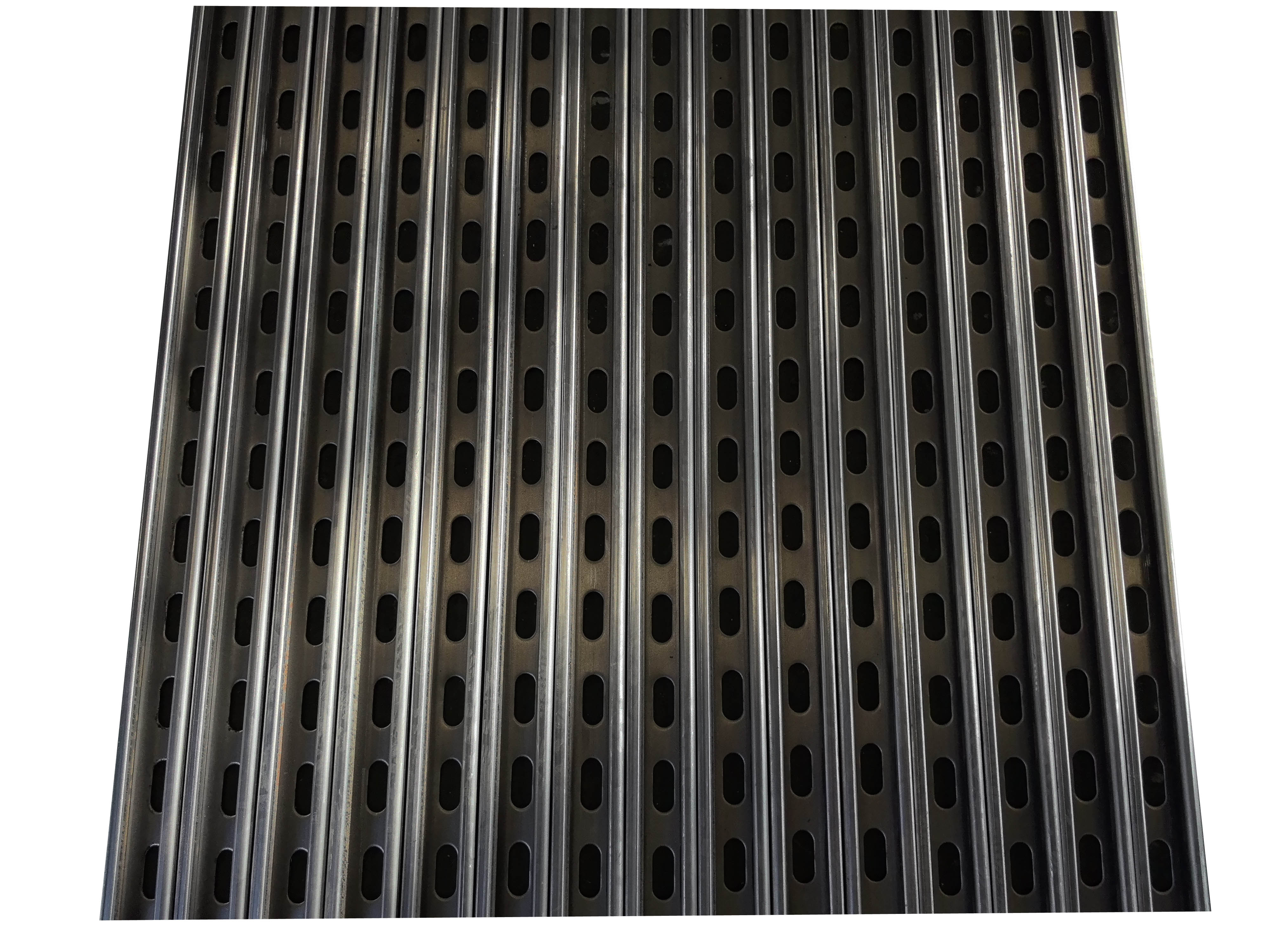

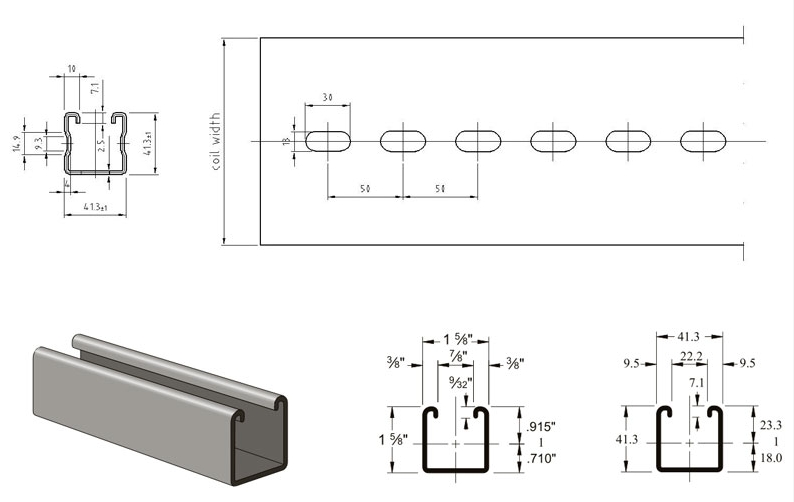

Effective Width: 41mm Effective Width Tolerance: ±0.5mm

Material Thickness:2.0-2.8mm The Length Of Tolerance:±1(4m)

Applicable Material:Galvanized Sheet(GI) Inspection Thickness:2.0mm

Cold Roll Steel(CRC)

With yield strength 235Mpa-550Mpa

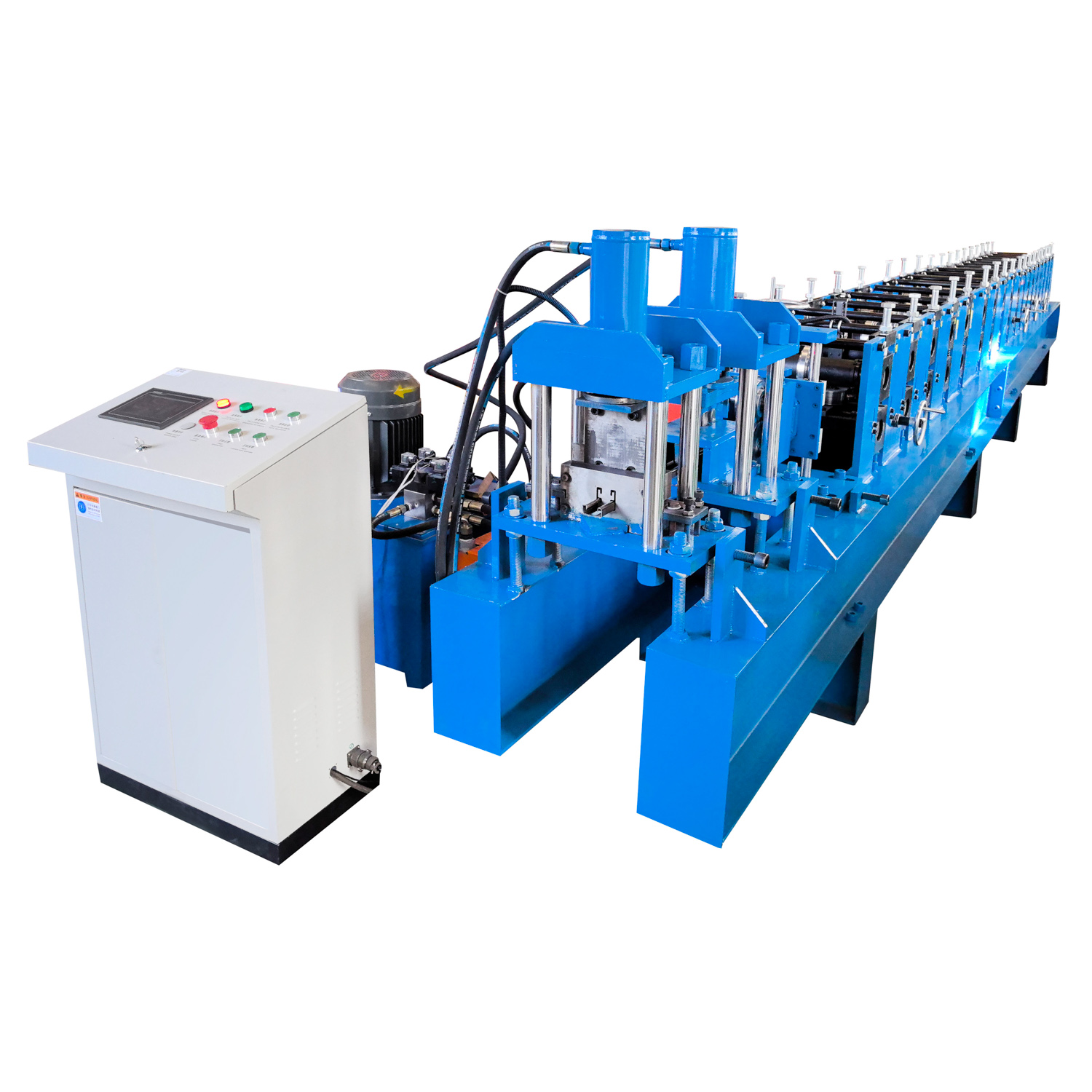

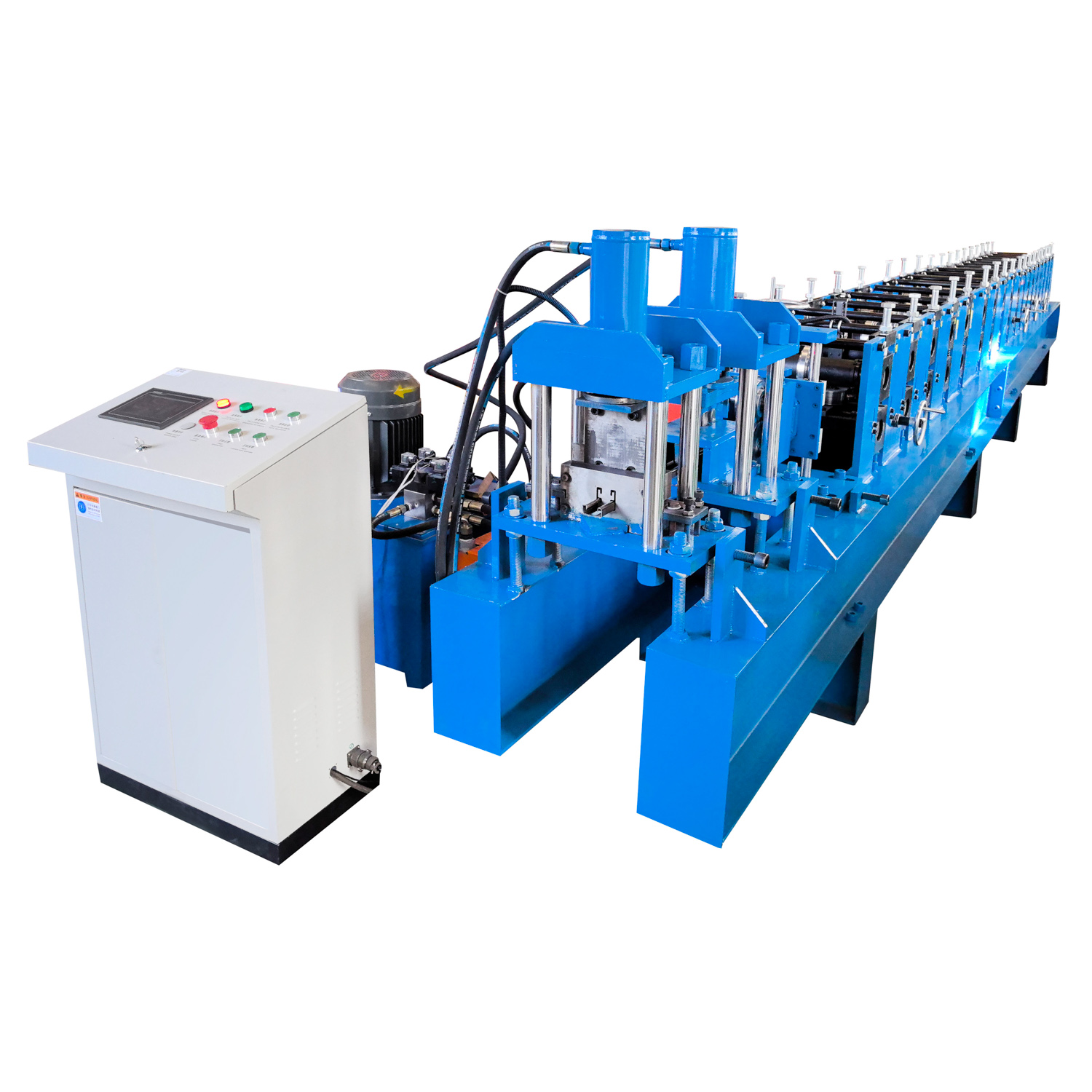

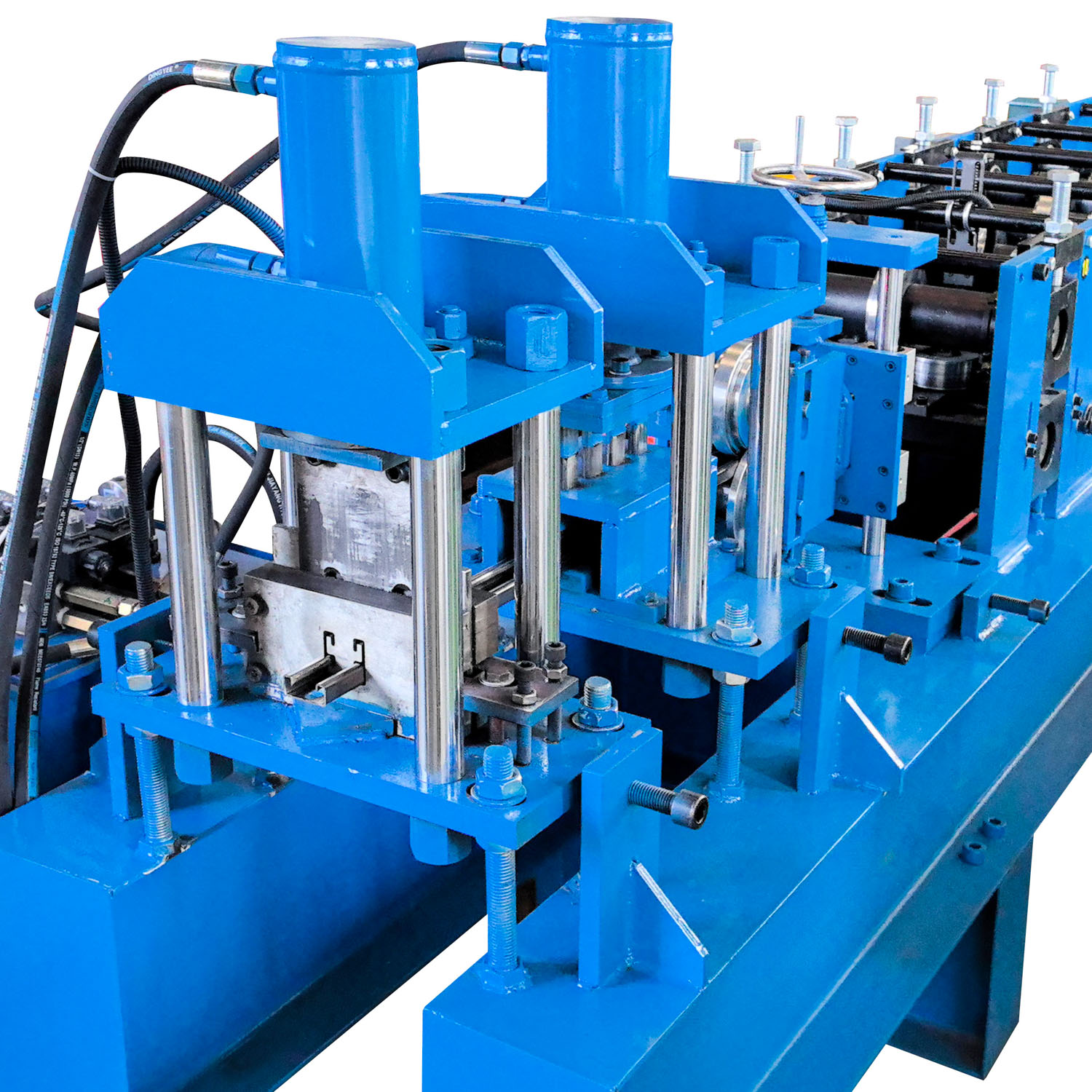

Introduction of roll forming machine:

Body frame made from H350 type steel by welding

Side wall thickness: Q235 t18mm ;

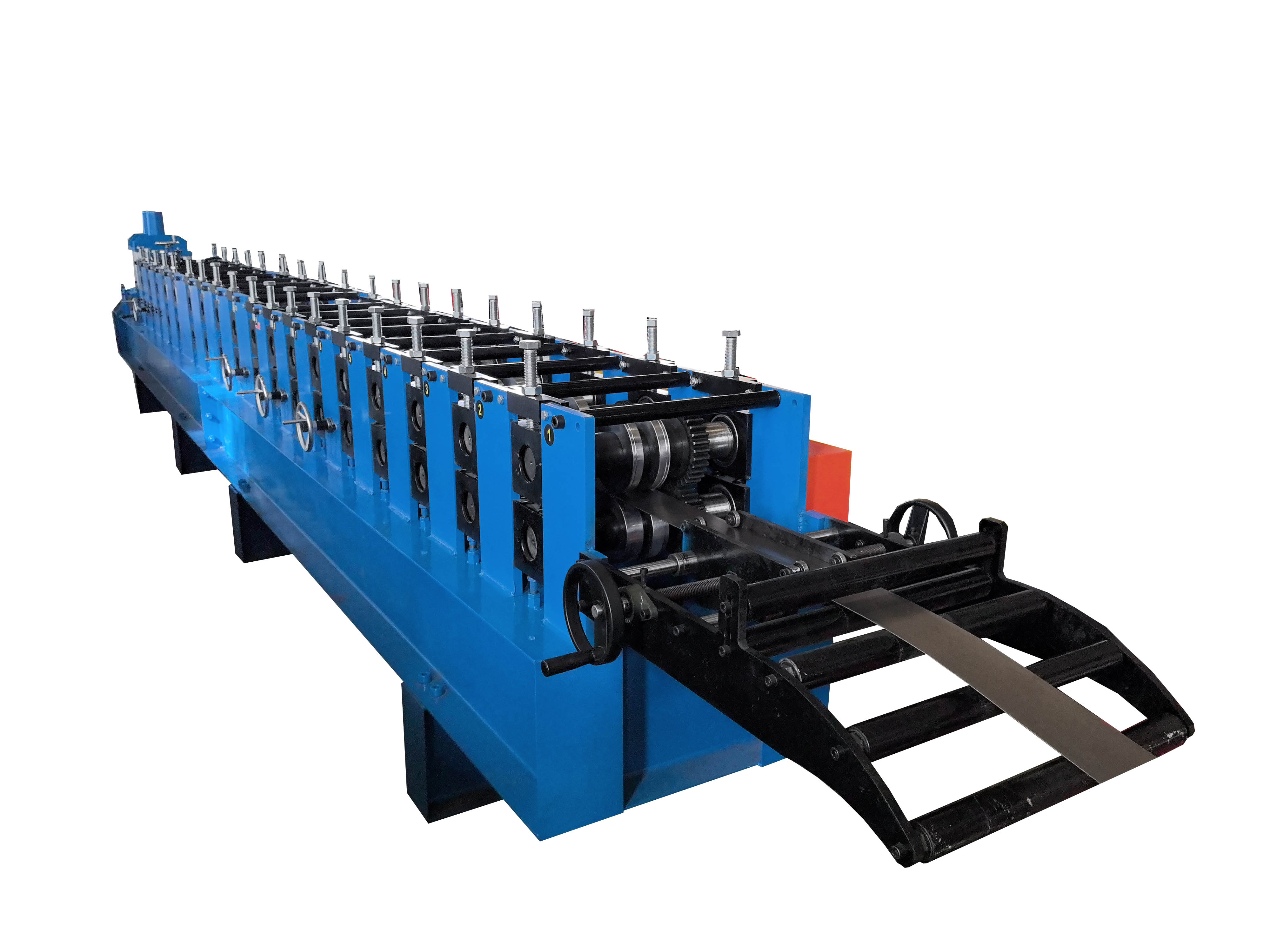

Rollers manufactured from Bearing steel GCr15,precision machined,hard Chrome Coated;

Shafts manufactured from 45# steel,Quenching and tempering heat treatment, hard chrome plating.Diameter=φ75/85mm,precision machined

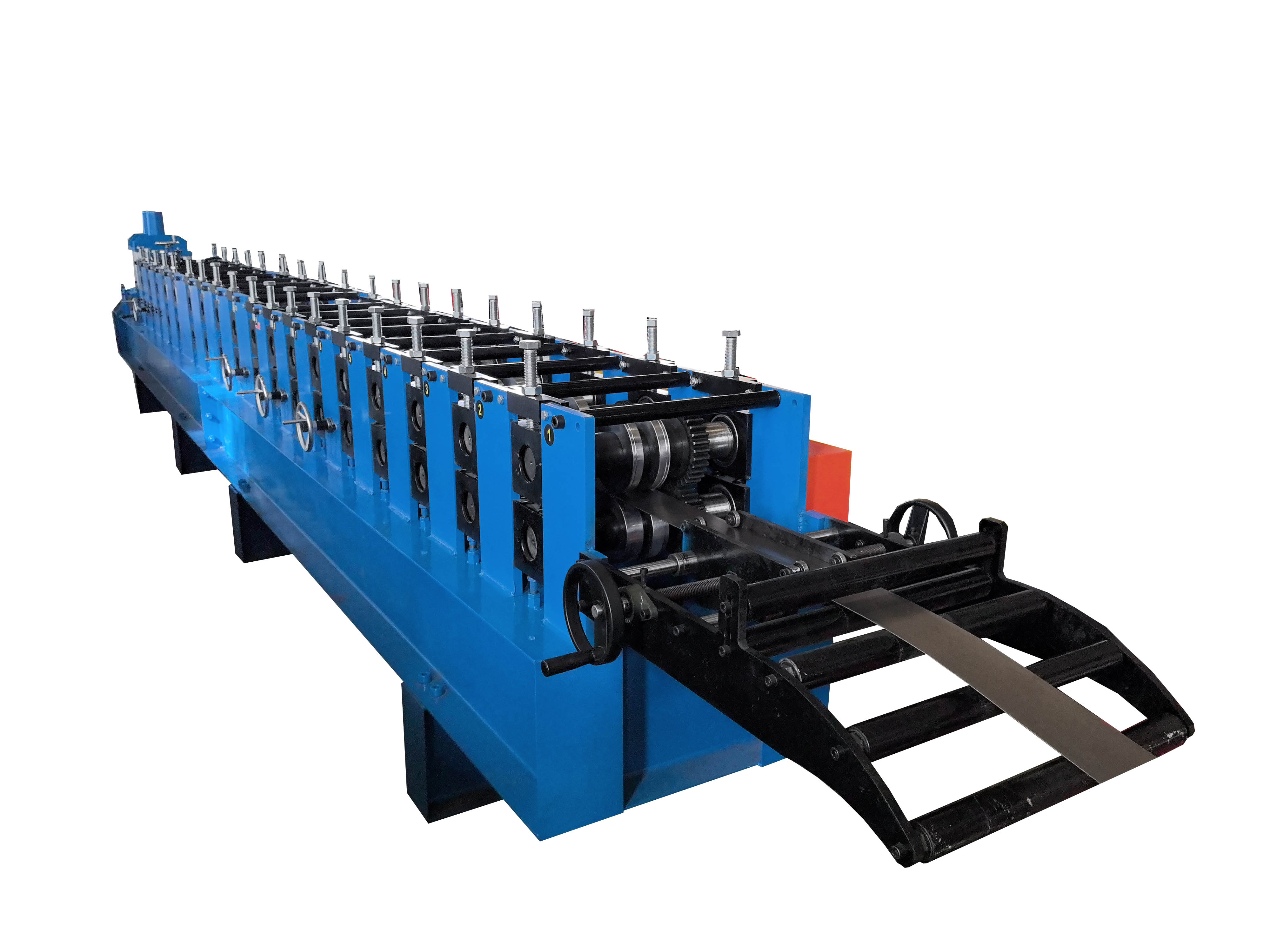

Gear & chain drive about 22-step to form

Main Motor=11KW ,Frequency speed control

Speed reducer motor:K series

Product speed:12-18m/min(Including punching and cutting time)

Working Flow:

Decoiler---Roll Forming Machine---Punching Holes---Hydraulic Cutting---Run Out Table

This machine use metal coil as material, through decoiler, roll former, automatic length sizing, cutting off to form special size profile. The whole line use PLC control, AC frequency control to realize continuous automatic production.

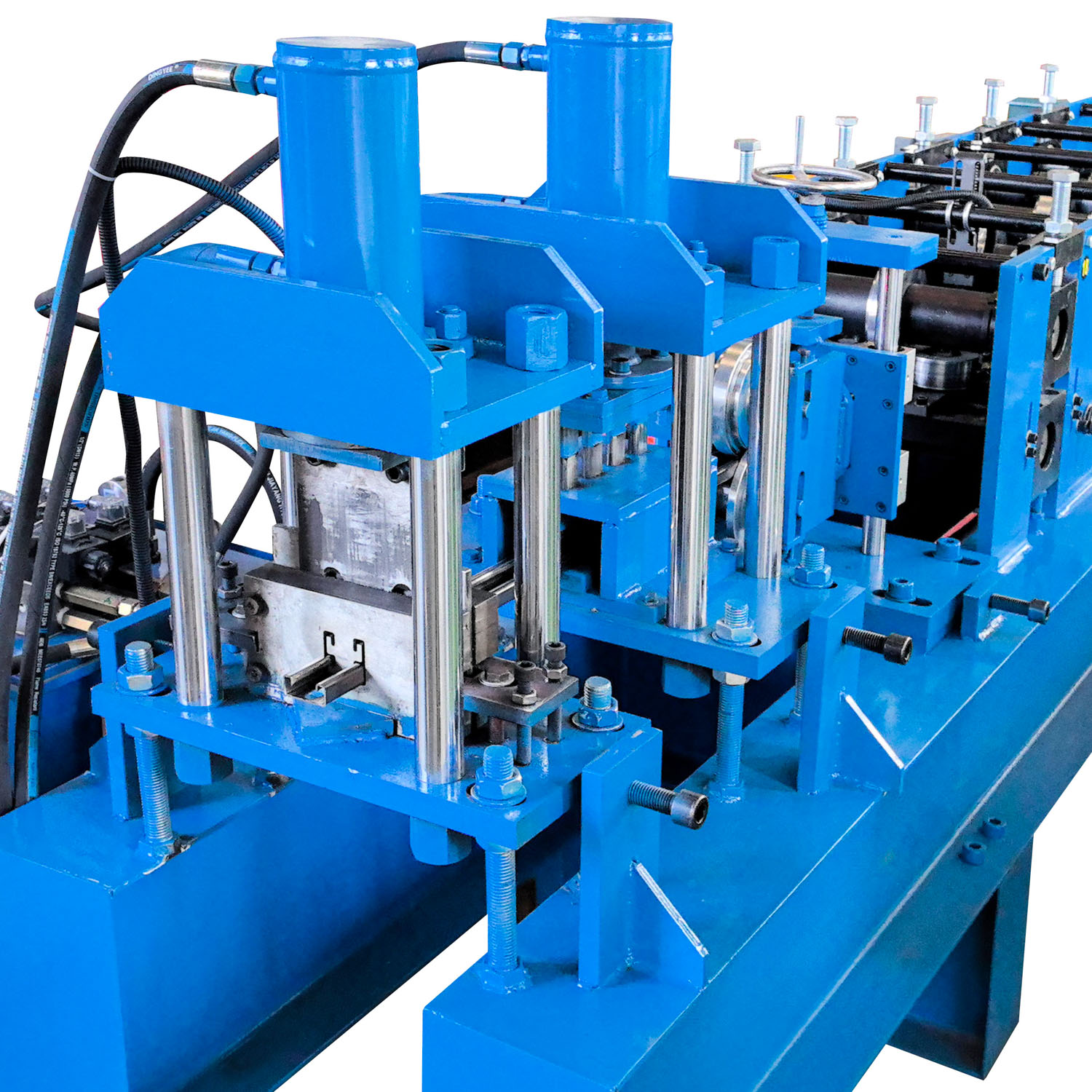

Punching holes by hydraulic on machine, it is good way for save cost. Kindly please send your requst to us, then we would like to do solution for you.

We test machine before delivery, we must be to confirmformed size, holes size, length,everything in good situation.

Specification:

No. | Item | Unit |

|

Design 1 |

1. | Material Of Processing |

| Galvanized Steel |

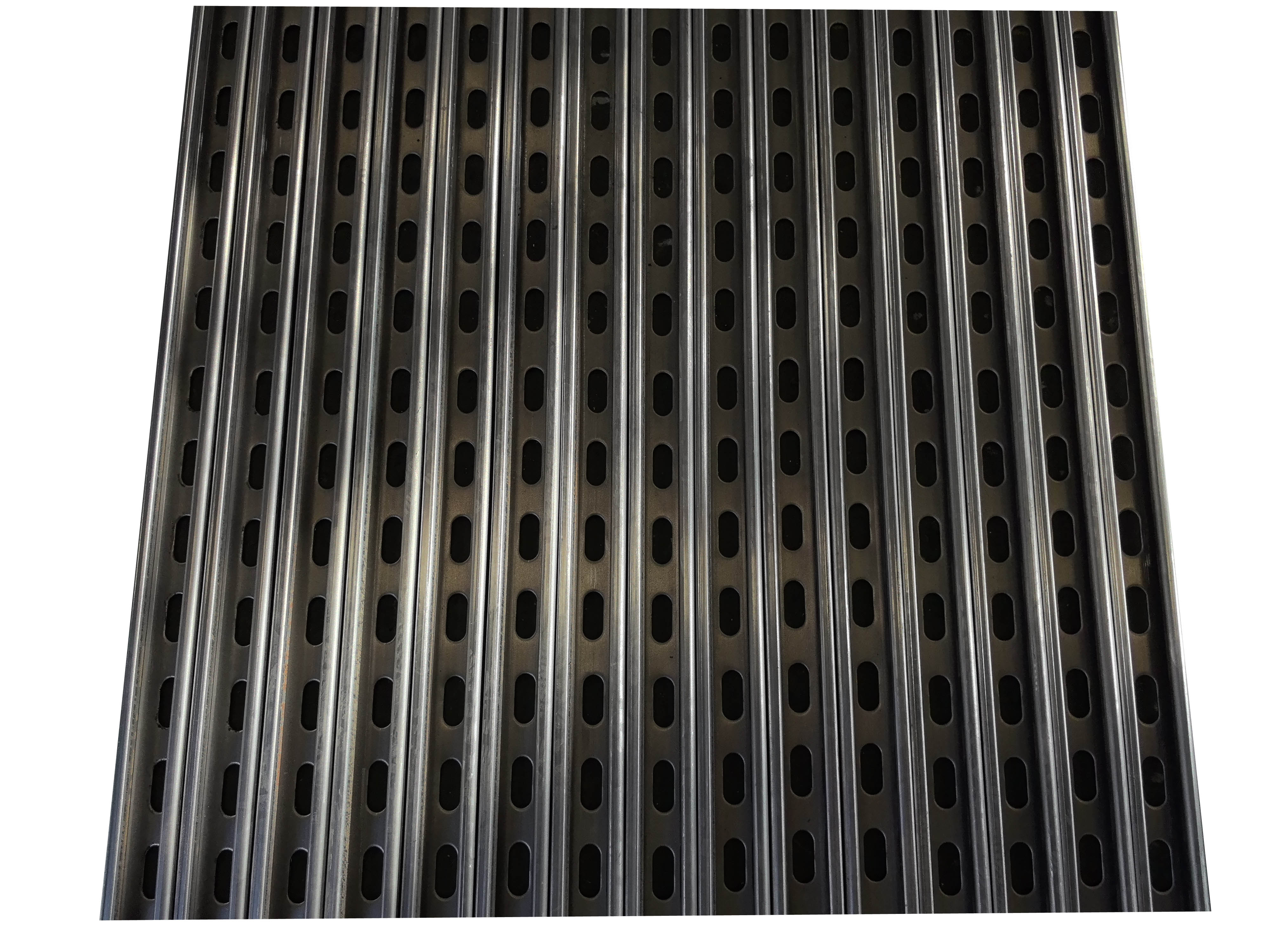

2. | Profile Type |

| 41*21,41*41 |

3. | Feed coil Thickness | mm | 2.0-2.5 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 80 |

7. | Roll Station | No. | 21 |

8. | Rolling material |

| GCr15 |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

Main Power |

|

| KW | 11 |

Cutting Machine |

10. | Type |

| PLC controlled Mold Cutting with flying servo motor |

11. | Thickness capacity | mm | 2.0-2.5 |

12. | Width capacity | mm | As drawing |

13. | Cutting blade steel grade |

| Cr12, quenching |

14. | Hardness |

| 58-62 HRC |

15. | Cutting tolerance | mm | +/- 1 |

Control Unit |

16. | Type |

| PLC controlled |

17. | PLC brand |

| Xinjie |

18. | Frequency conveter |

| Xinjie |

19. | Frequency converter power | kw | 11 |

20. | Dimension Of Machine | m | 11.5m*1.5m*1.4m |

21. | Weight | kgs | 4500-5000 |

22. | Working speed | m/min | 10m/min |

Use:

The bracket has a strong adjustable ability, high structural strength, beautiful shape, standard bending angle, accurate hole position, straight angle, accurate size, complete specifications, and economical price, which can meet most of the needs of customers.

Warranty:

warranty: 1 year warranty from date of shipment

guarantee:

1: guaranteed against malfunctions due to manufacturing defects for 1 year after date of shipment. repairs will be made free of charge.

2: repairs will not be performed free of change even during the guarantee period in the follow circumstances

- damage occurs due to a natural disaster

- malfunction occurs due to user error

- malfunction occurs due to modifications

- malfunction occurs due to further movement or shipment after installation

3: air ticket, transportation cost, hotel, meals and 150$ per day shall be for purchaser's account if manufacturer's engineer has to be send to purchaser's factory to maintain the machine during the guarantee period.

Servies

Zunsheng's Online Service. Zunsheng Machinery Services Online gives you fast and easy online access to your Installed Base to order original spare parts and explore the Options & Upgrades relevant for your line.

It is a user-friendly interface, available 24/7, in 9 languages, and is your one-stop online shopping. Designed to make your life easier in your day to day business, it will help you to improve your line and maintain its performance.

Zunsheng Services Online helps you:

1 - Machine running video

2 - Watch our factory online

3 - Supply a running line in your country, you can see the machine running directly.