Downspout Roll Forming Machine

We are specialized manufacturers of downspout forming machine, downpipe roll forming machine that are used to provide the water system for buildings. We can design and manufacture downspout machines for forming different profiles according to customers' requirements.

We design rain gutter downsport roll forming machine use hydraulic cutting, it is working more faster and cutting no burrs.

Hydraulic Curve Downspout Machine:

Hydraulic curve downspout machine is used for after roll forming, it is can bending and shrink mouth,then downspout can connect together and it is easy install to house.

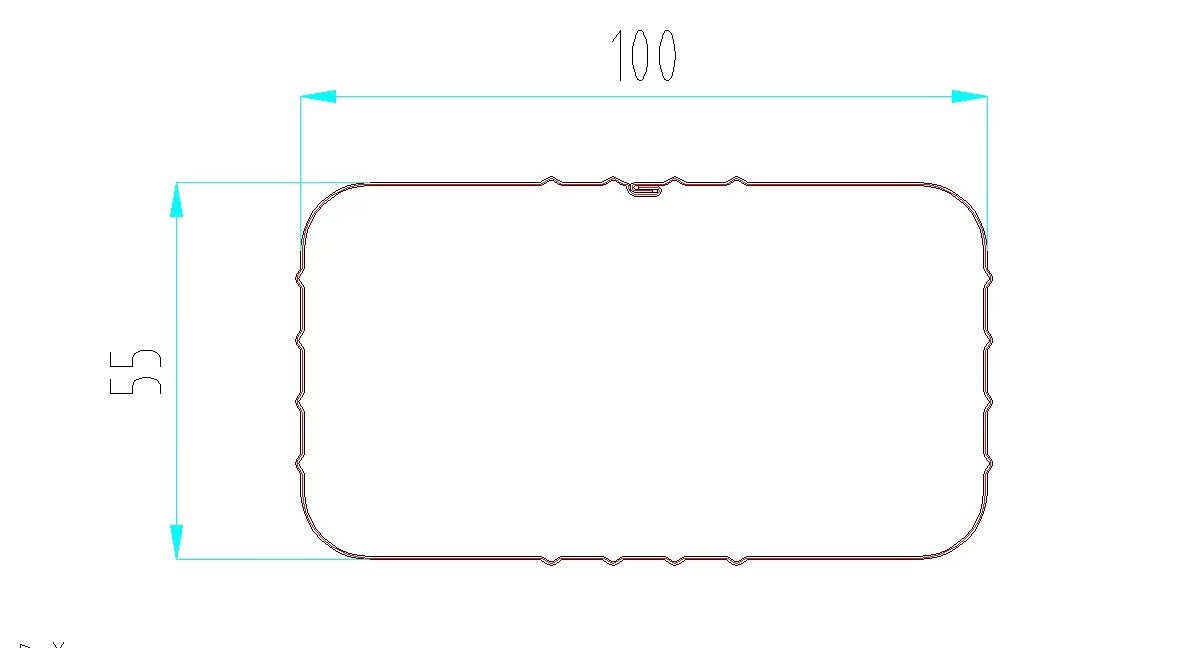

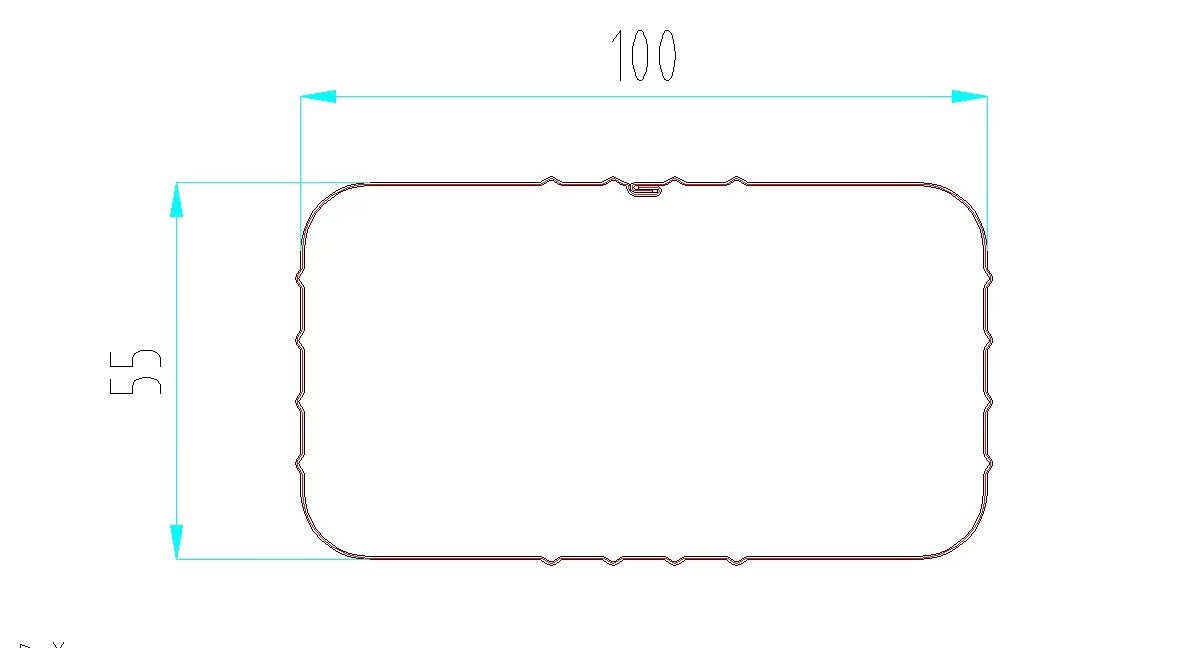

Specification:

No. | Item | Unit |

|

1. | Material Of Processing |

| PPGI |

2. | Profile Type |

| As customer’s request |

3. | Feed coil Thickness | mm | 0.5-0.8 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 70 |

7. | Roll Station | No. | 22 |

8. | Rolling material |

| GCr15 |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed |

| About 12-15 m/min |

11. | Drive Type of Roll Forming Machine |

| Chain |

12. | Power of Main Motor | kw | 11 |

Cutting Machine |

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 0.5-0.8 |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Delta |

21. | Frequency converter power | kw | 7.5 |

22. | Dimension Of Machine |

| About 11m*1.2m*1.4m |

23. | Weight | kgs | 5500 |

24. | Working area | m | 20*3 |

25. | Voltage |

| 3800V,50HZ,3Phase |

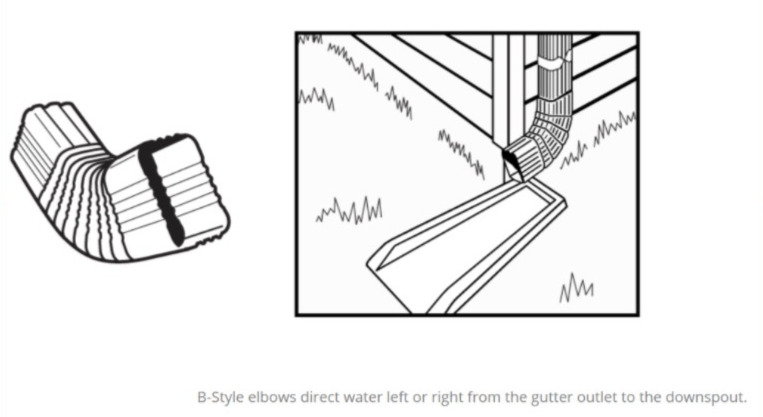

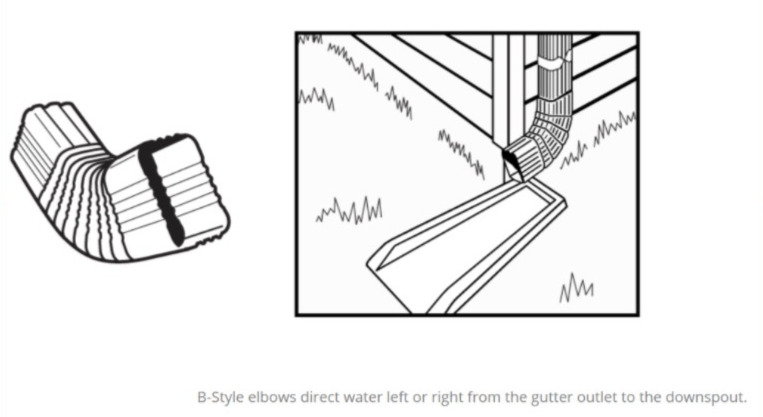

Use:

The purpose of a downspout is to allow water from a gutter to reach the ground without dripping or splashing down the building structure.