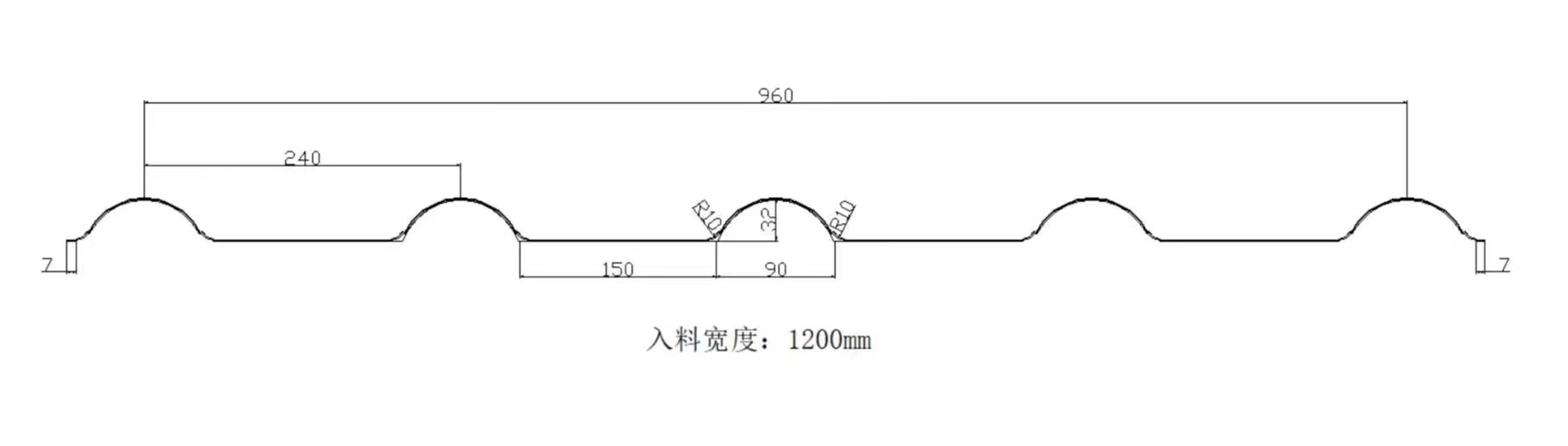

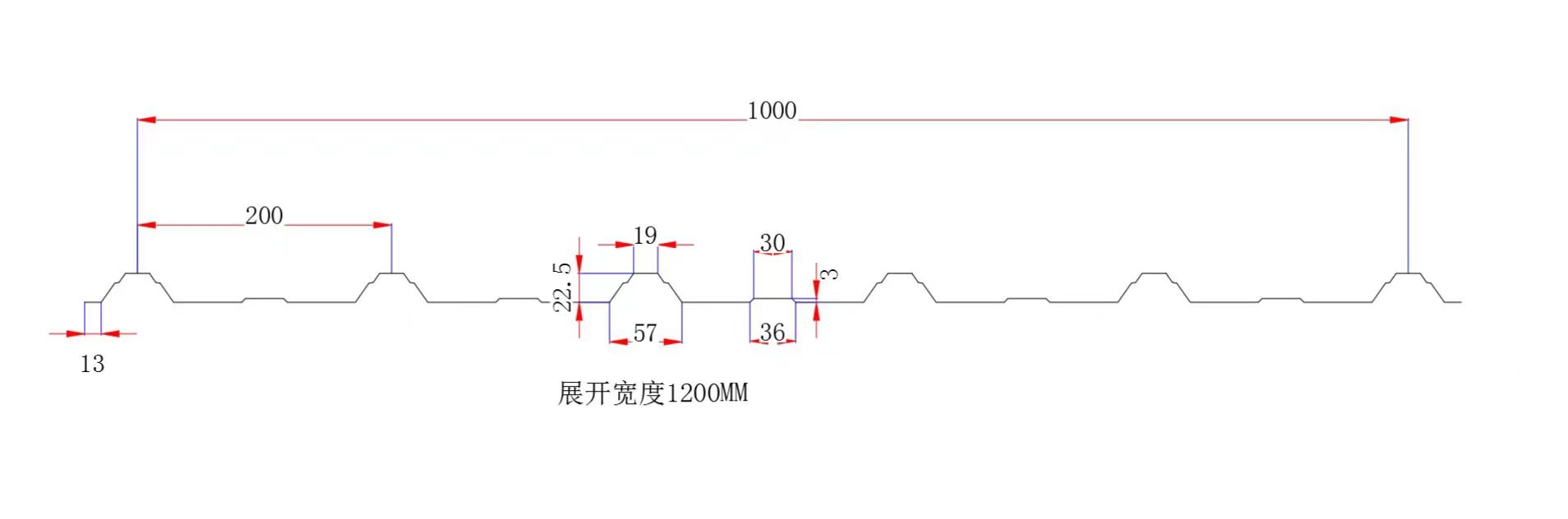

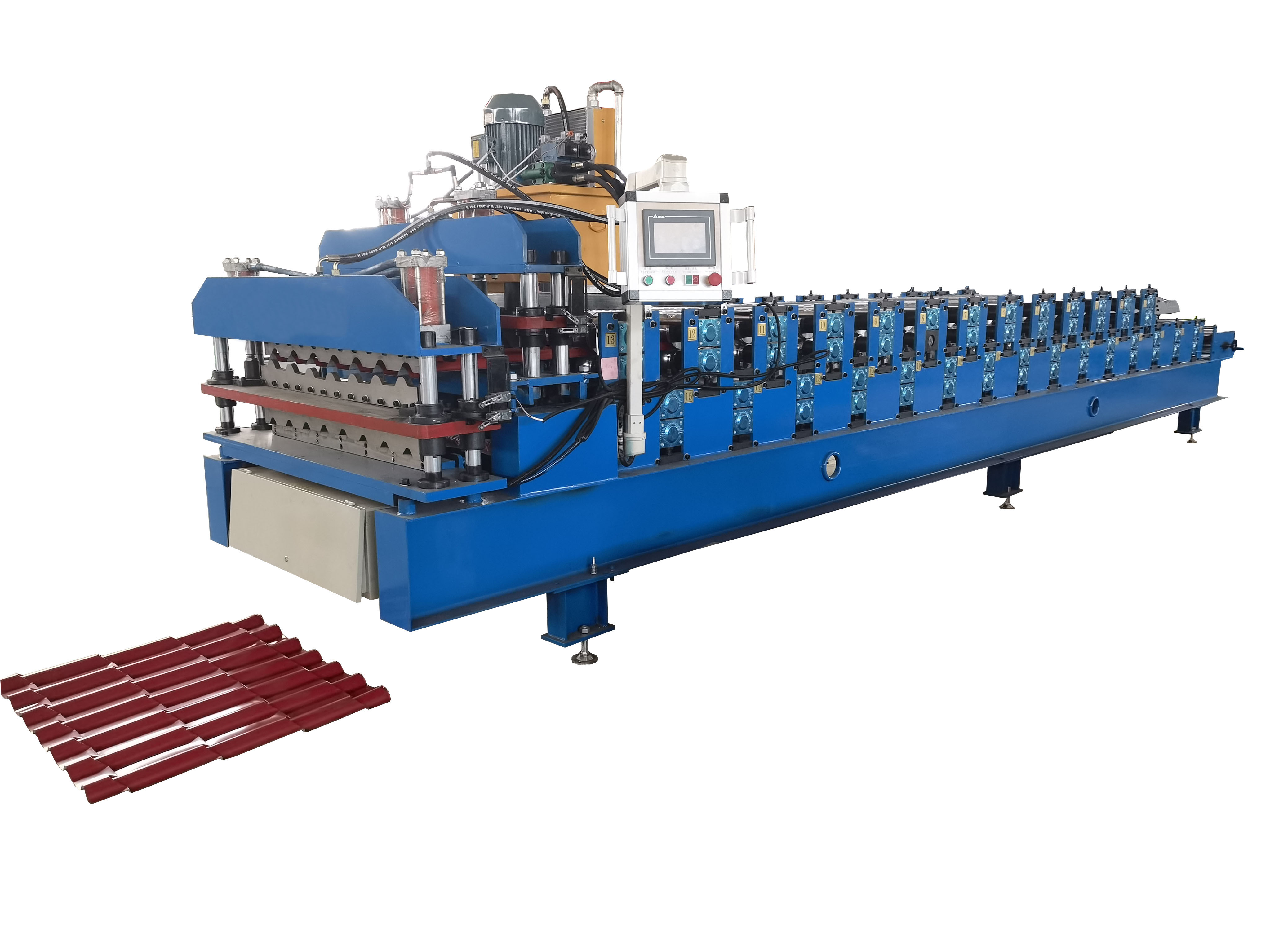

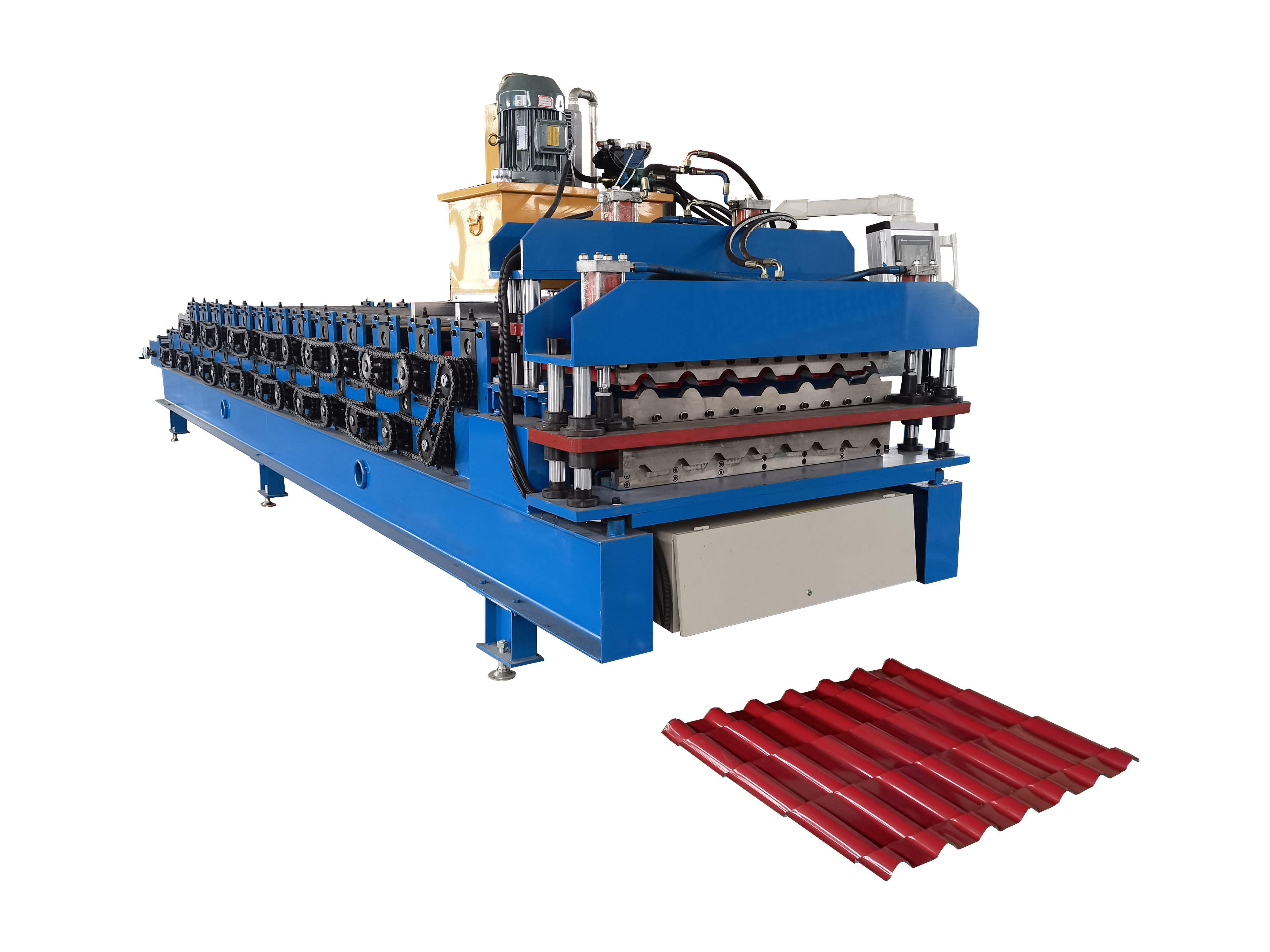

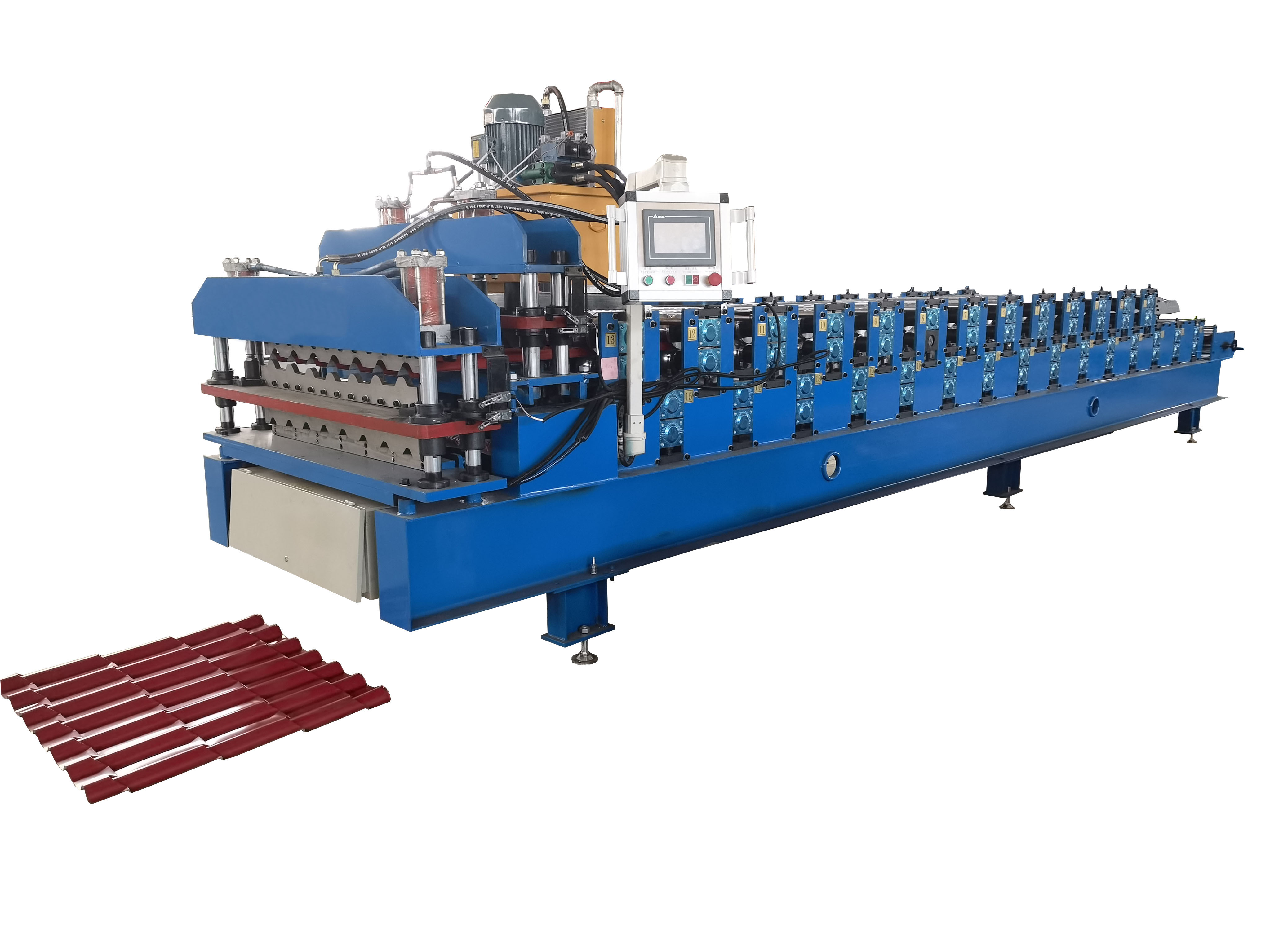

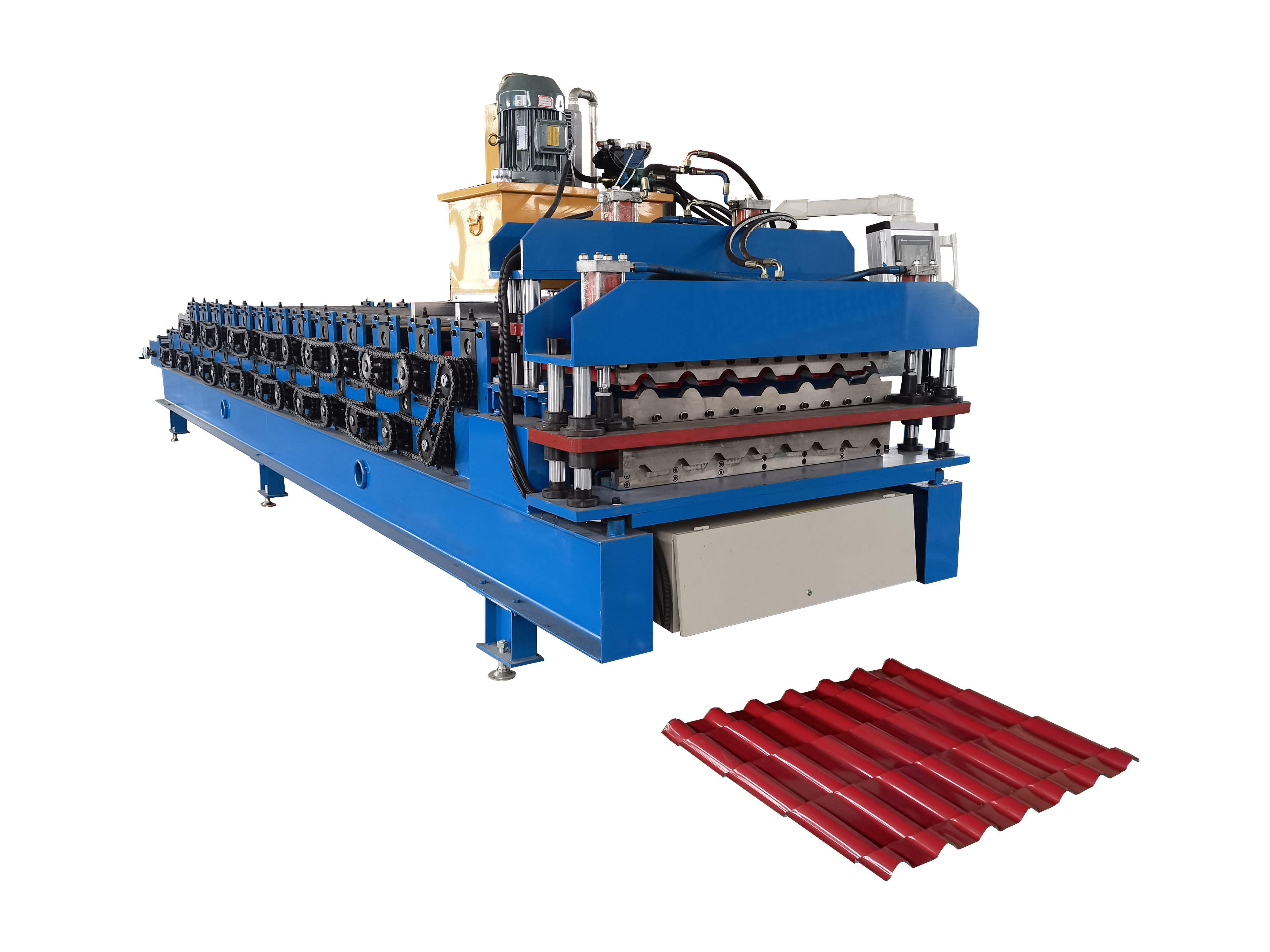

Peru Mectoppo plancha Glazed Tile And TR 5 TR4 Double Layer Roof Sheet Roll Forming Machine

High Quality Automatic Glazed Tile And TR6 Trapezoidal Roofing Sheet Double Layer Roll Forming Machine For Building Material Machine.

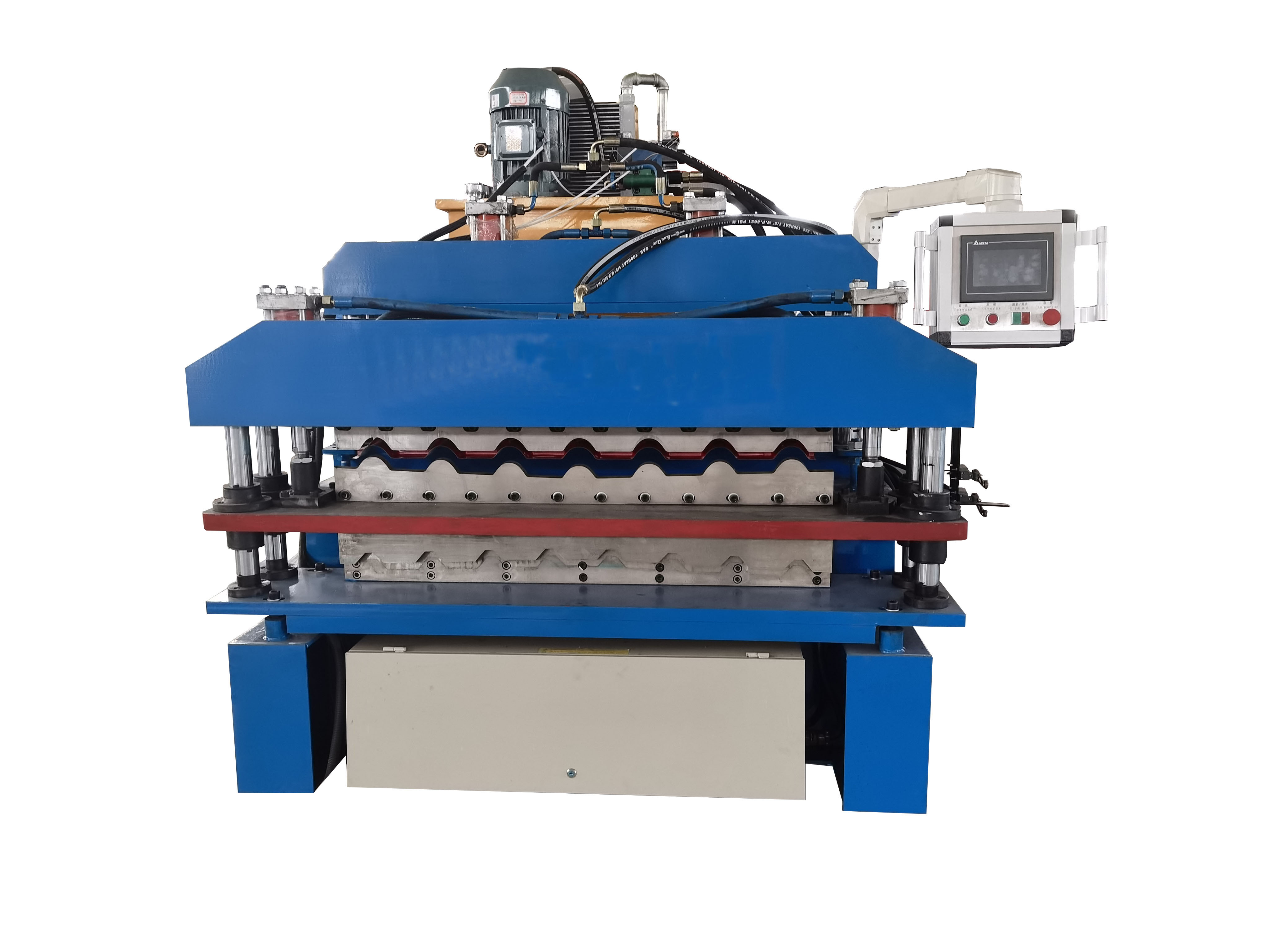

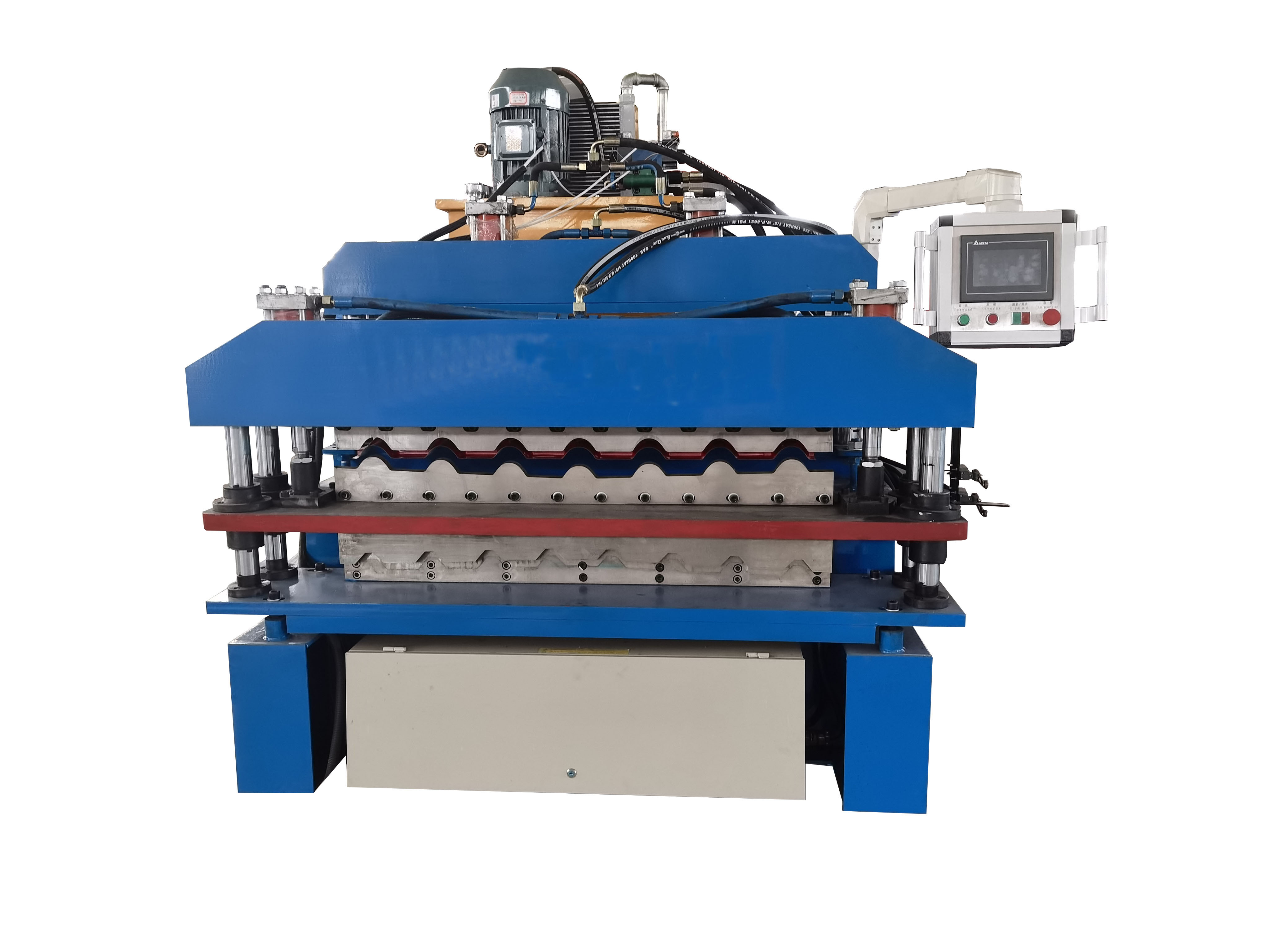

We can choose up layer or down layer working by PLC, two layers can not working in the same time.

Machine driven by servo motor, it is can improve working speed, glazed tile forming speed is 3-5m/min, TR6 forming speed is 20-30m/min.

Working Flow:

Decoiler---Feeder and Pre Cutting---Roll Forming Machine---Hydraulic Cutting System---Run Out Table

Specification:

No. | Item | Unit |

|

| Double Layer Roll Forming Machine |

1. | Material Of Processing |

| PPGI,GI |

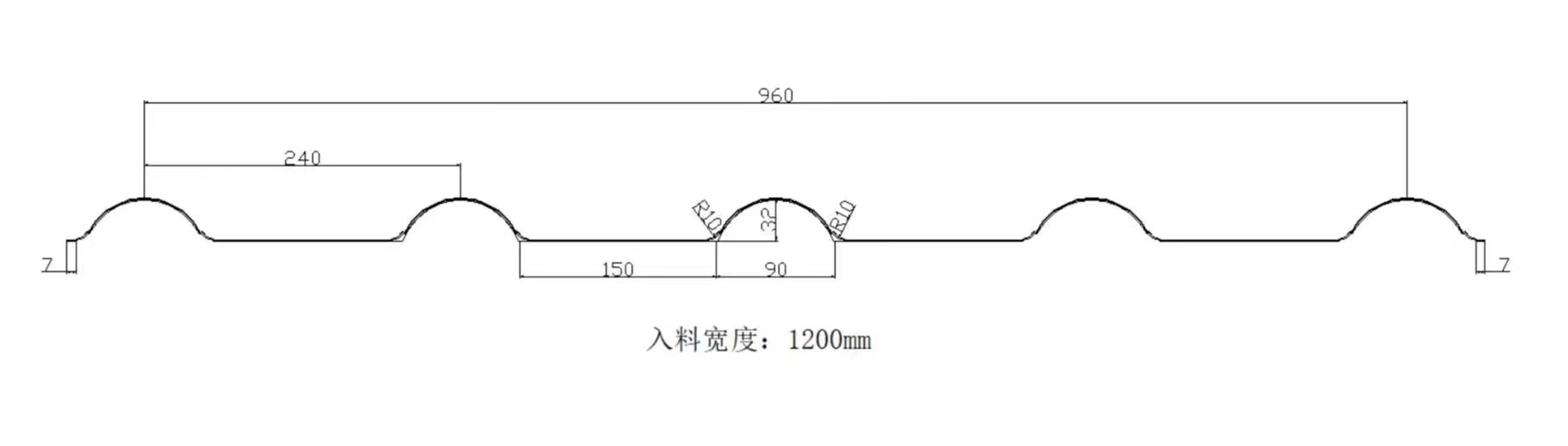

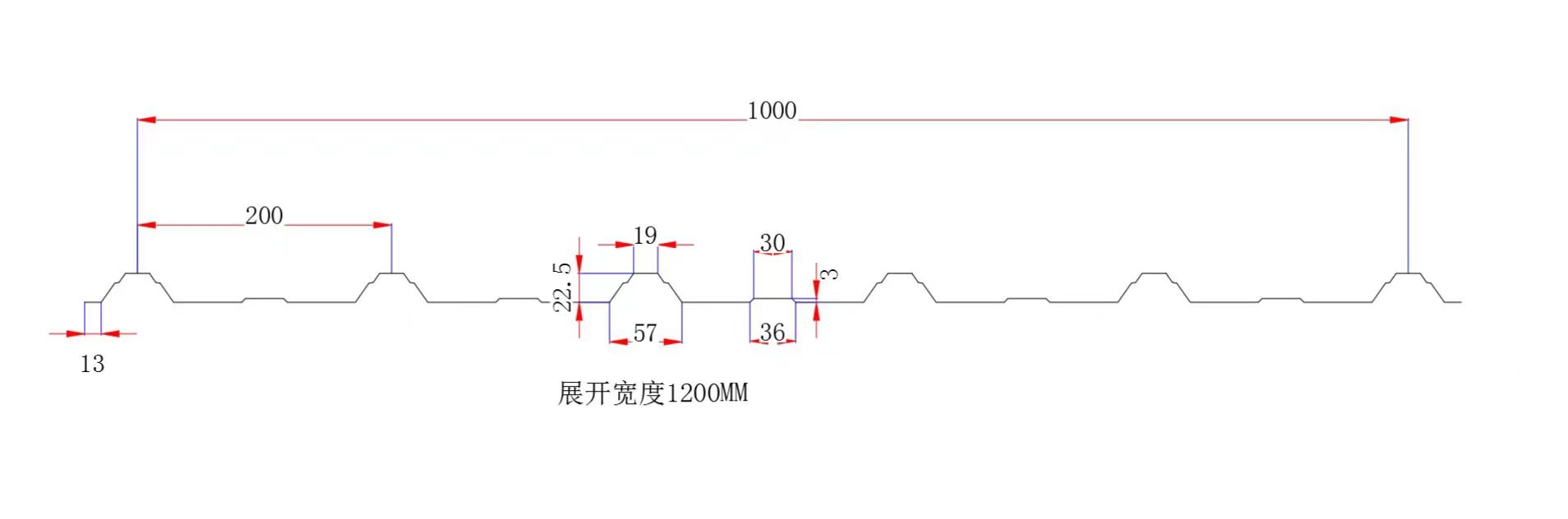

2. | Profile Type |

| As customer’s request |

3. | Feed coil Thickness | mm | 0.3-0.6 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 70 |

7. | Roll Station | No. | 15-18 |

8. | Rolling material |

| 45#steel |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed | m/min | 15-20 |

11. | Drive Type of Roll Forming Machine |

| Chain |

12. | Power of Main Motor | kw | 5.5 |

Cutting Machine |

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 0.3-0.6 |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

19. | Power of hydraulic | kw | 5.5 |

Control Unit |

20. | Type |

| PLC controlled |

21. | PLC brand |

| Delta |

22. | Dimension Of Machine | mm | 7600*1350*1400 |

23. | Weight | kgs | 7500 |

24. | Working area | m | 20*3 |

25. | Voltage |

| 220V,60HZ,3Phase |

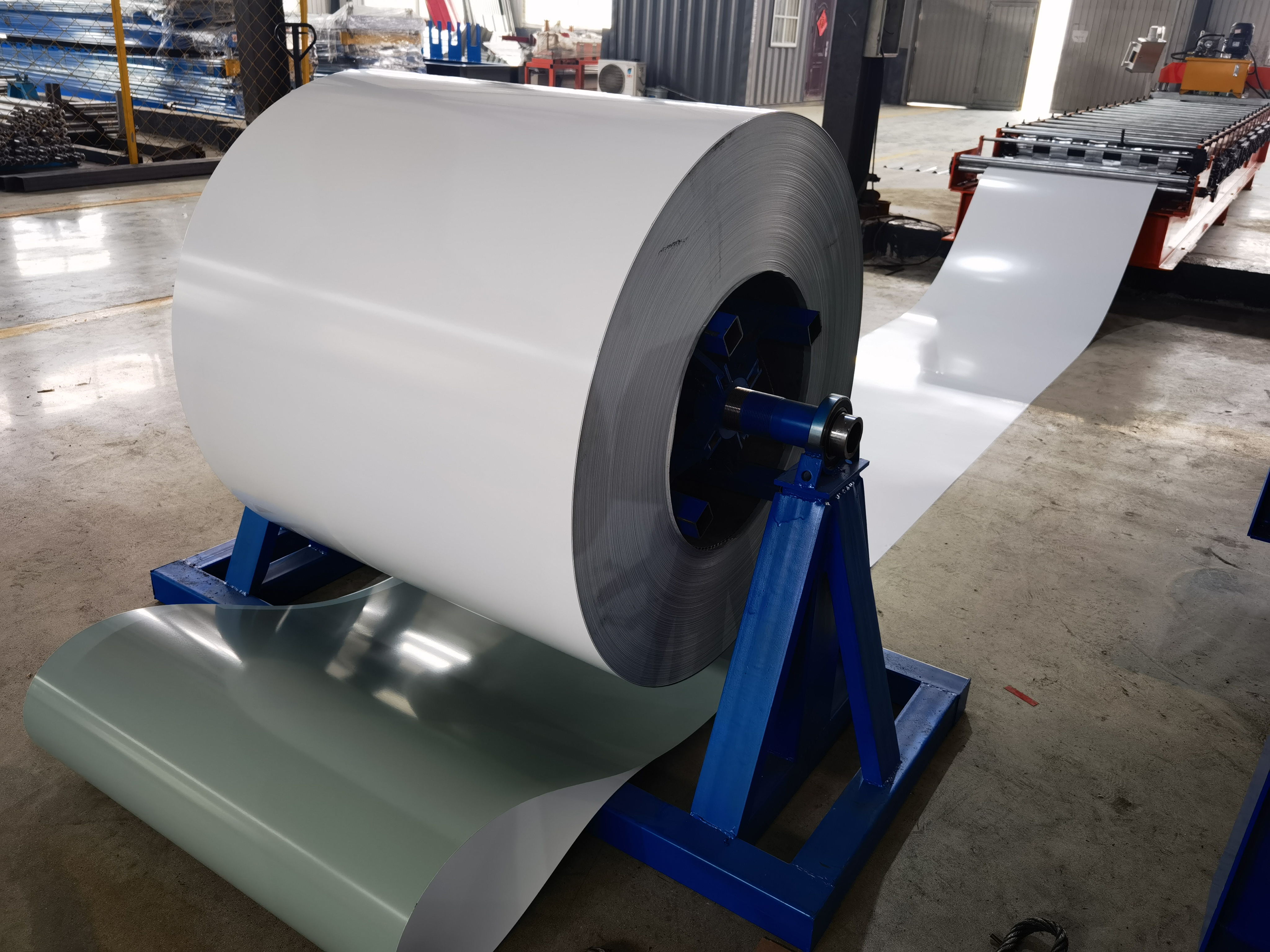

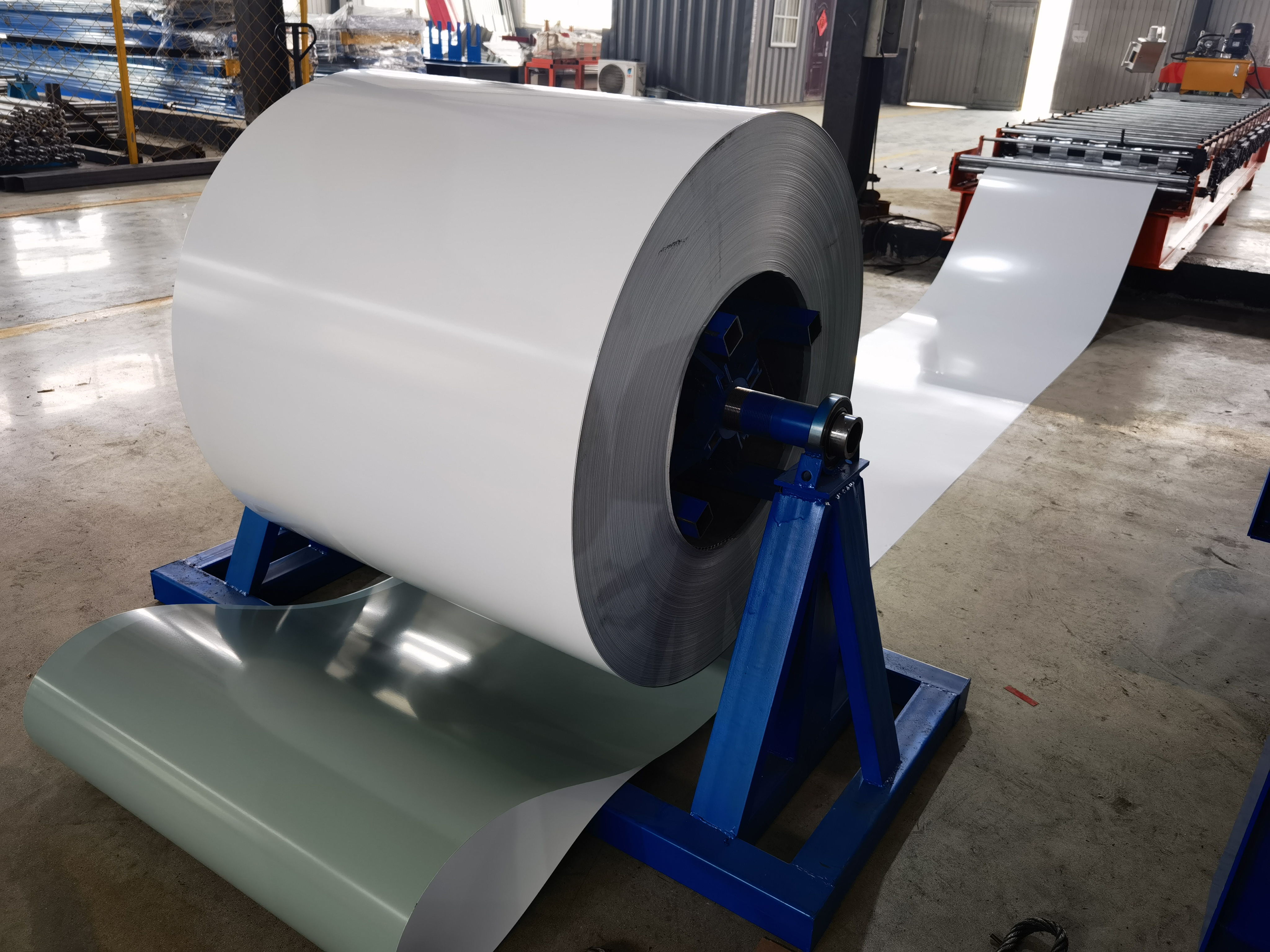

We have manual decoiler and automatic decoiler can choose:

We have simple automatic table and full automatic storage table can choose and customize the length follow with your requirement.

Advantages:

1.High quality rollers with hard treatment and chrome coating.

2.We can meet all of your customize requirements,and manufacture many kinds of roll forming machine.