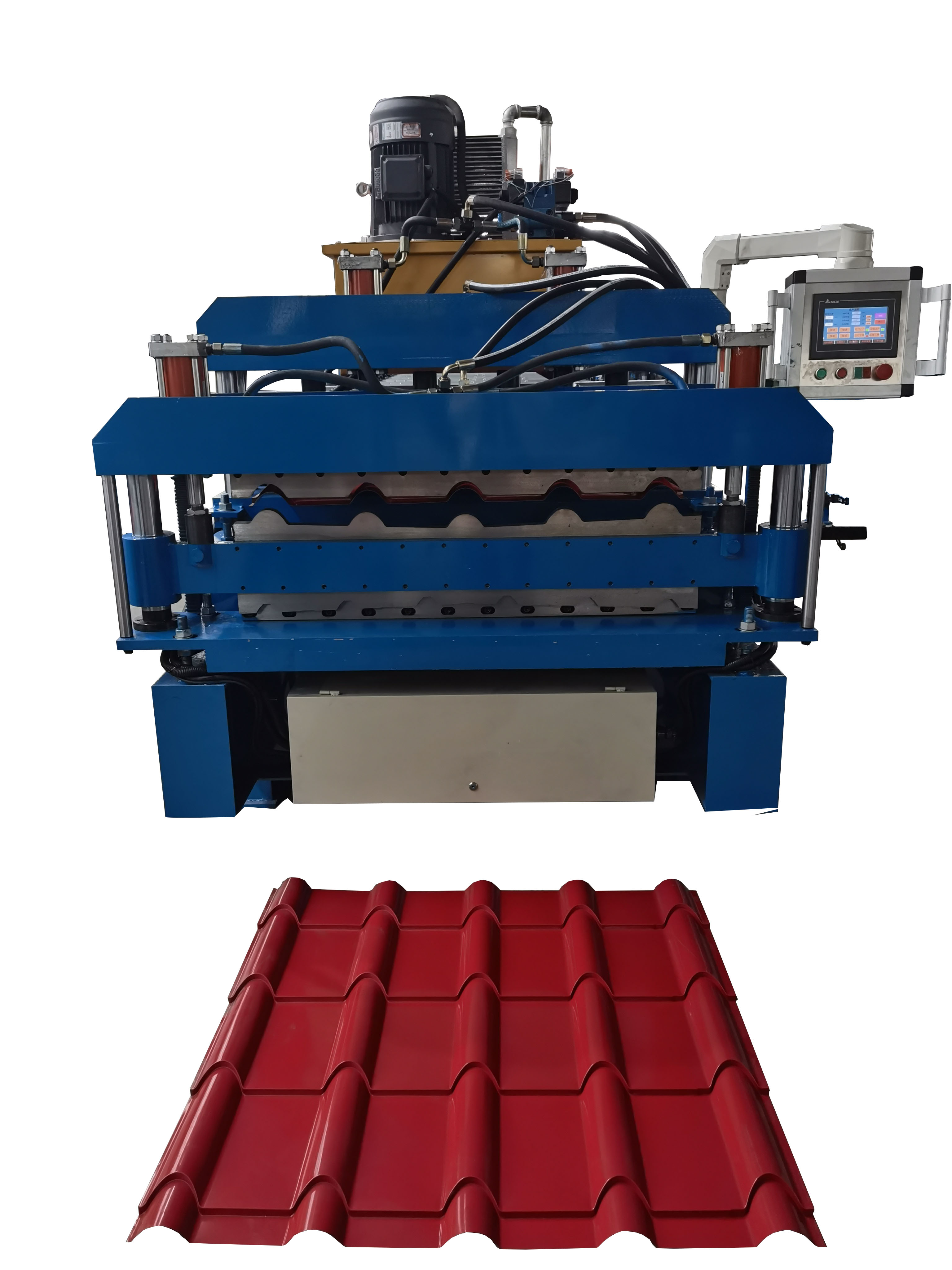

Double Layer Roof Sheet Roll Forming Machine

It is customize double layer roll forming machine, we will design the machine follow with your size,thickness and voltage. Please send your requirement to us,then our engineer will make drawing and confirm with you.

Double layer roll forming machine is suitful of limited workhouse, we can choose up layer or down layer working from PLC.

Advantage:

1.Double layer roof sheet roll forming machine can produce two design by one machine, so it is can save cost for customer, and it is suitable for small workhouse.

2.Machine wokrs stably and it is not prone to malfunctions.

3.Save labor,one worker can operating this machine.

4.High efficiency, this machine every hour can produce 200-800m.

Specification:

| Items | Double Layer Roofing Sheet Roll Forming Machine |

| Total power | 5.5kw(3 phase,50 hz /60ha,380v/220v/230v/440v) |

| Speed | 0-25m/min |

| Dimension(L*W*H) | 9m*1.4m*1.6m |

| Weight | 6.5 tons |

| Roller station | 18-16 pairs |

| Frame | Cast frame+tube/steel box/ Steel plate+ 350H Steel |

| Material thickness | 0.3-0.6mm |

| Material width | Follow with design |

| Transmission system | Chain |

| Cutting system | Hydraulic cylinder(profile cutting system) Material SKD11 Japan |

| Control system | PLC,Xinjie/Delta |

| Runout table | Manual 3m |

| Decoiler | Manual / Electrical/Hydraulic, 5 tons/ 7 tons/ 10 tons |

| Equipment |

| PLC | Delta(China) |

| Touch panel | Delta(China) |

| Electric motor | BOJIANG(China) |

| Encoder,relay | OMRON(Japan) |

| Hydraulic components | GUOWEI(China) |

| Cutting blades | SKD11(Japan) |

| Rollers | 45#Steel |

Use:

| A roof is one of the essential components which protects the house from heat, cold, rain, and snow. A roof rests on a structural frame made of concrete or MS steel. |

FAQ:

1.How does your factory do regarding quality control?

There is no tolerance regarding quality control. Quality control complies with ISO 9001.every machine has to past testing running before it's packed for shipment.

2. How can I trust you that machines pasted testing running before shipping?

We record the testing video for your reference

We welcome you visit us and test machine by yourself in our factory.

3.What about our after-sale service?

We provide technical support on line as well as overseas services by skillful technicians.