0.3-3.0MM Automatic Slitting Line

A steel coil slitting line is used for slitting the carbon steel coils and hot dip galvanized coils to prepare for the next process. Slitting line is working for 0.2-3.0mm,1250mm-1500mm width, and decoiler recoiler can support 10-15 tons.

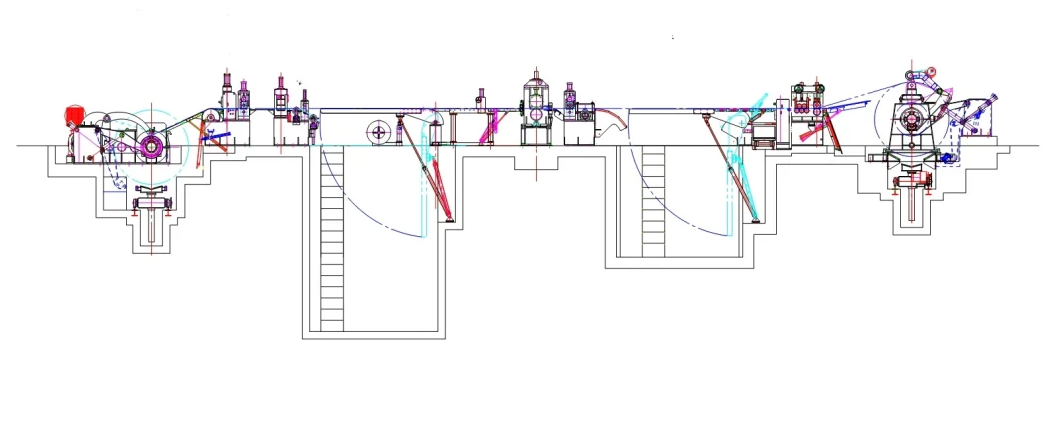

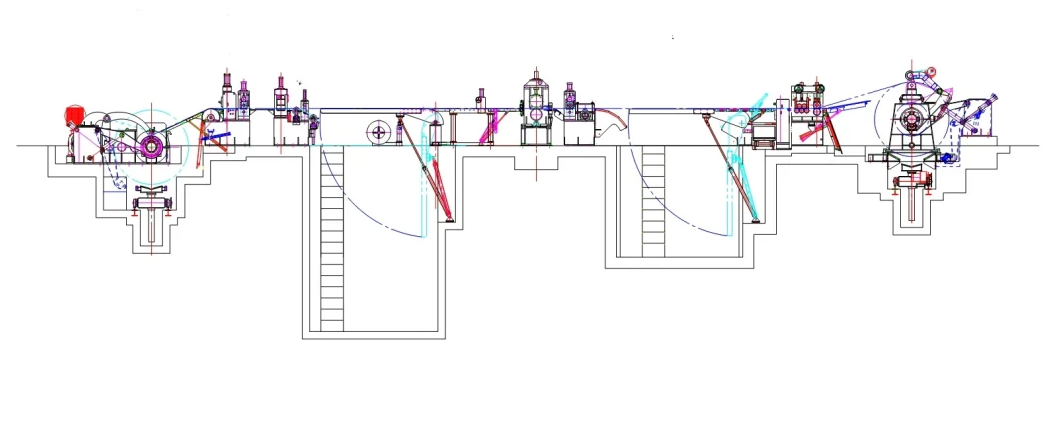

Working Flow

Hydraulic decoiling → Feeding sheet and Flattening sheet → Slitting sheet→ Scrap Winding→ Tighten the roll→ Hydraulic recoiler

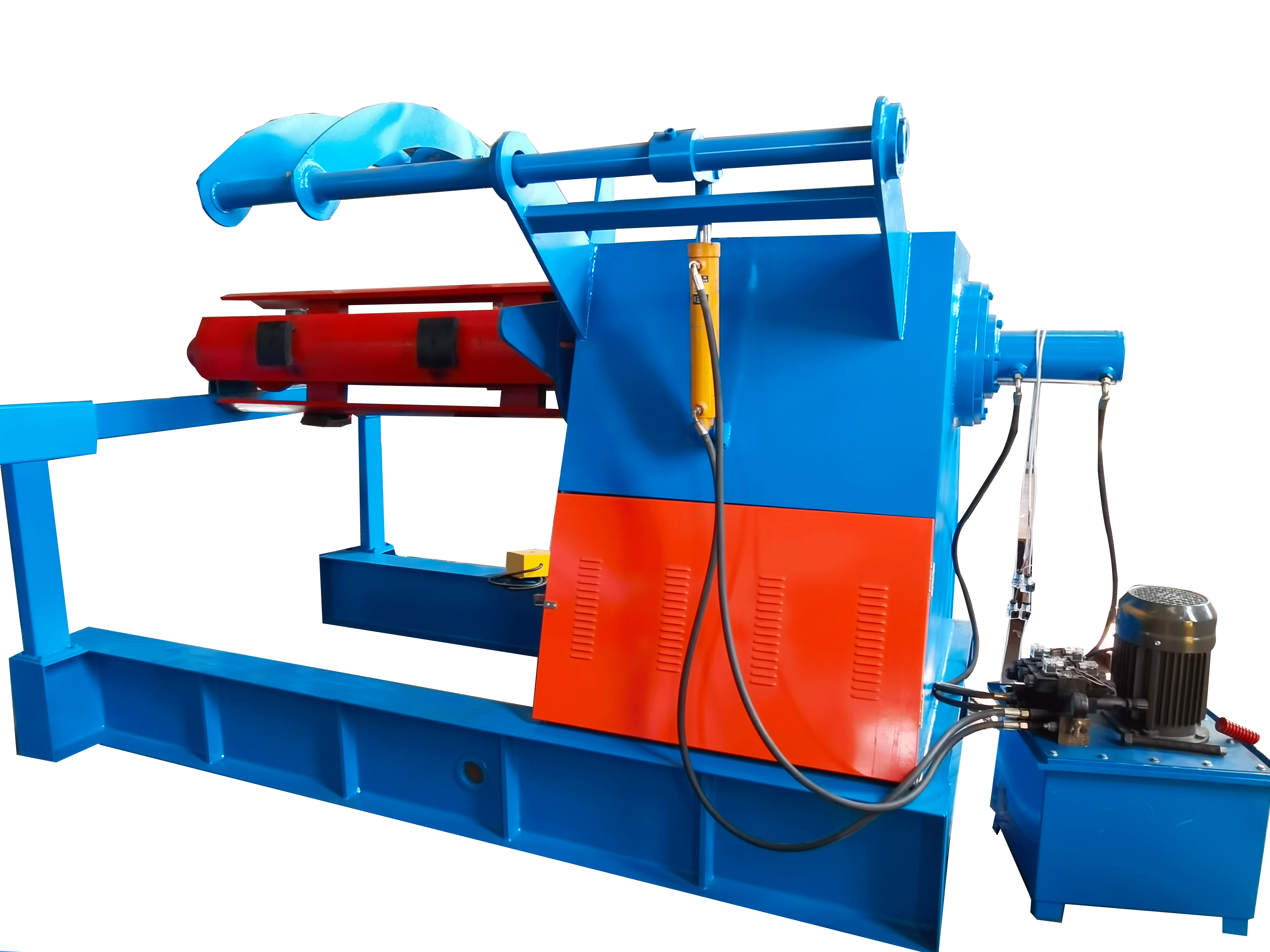

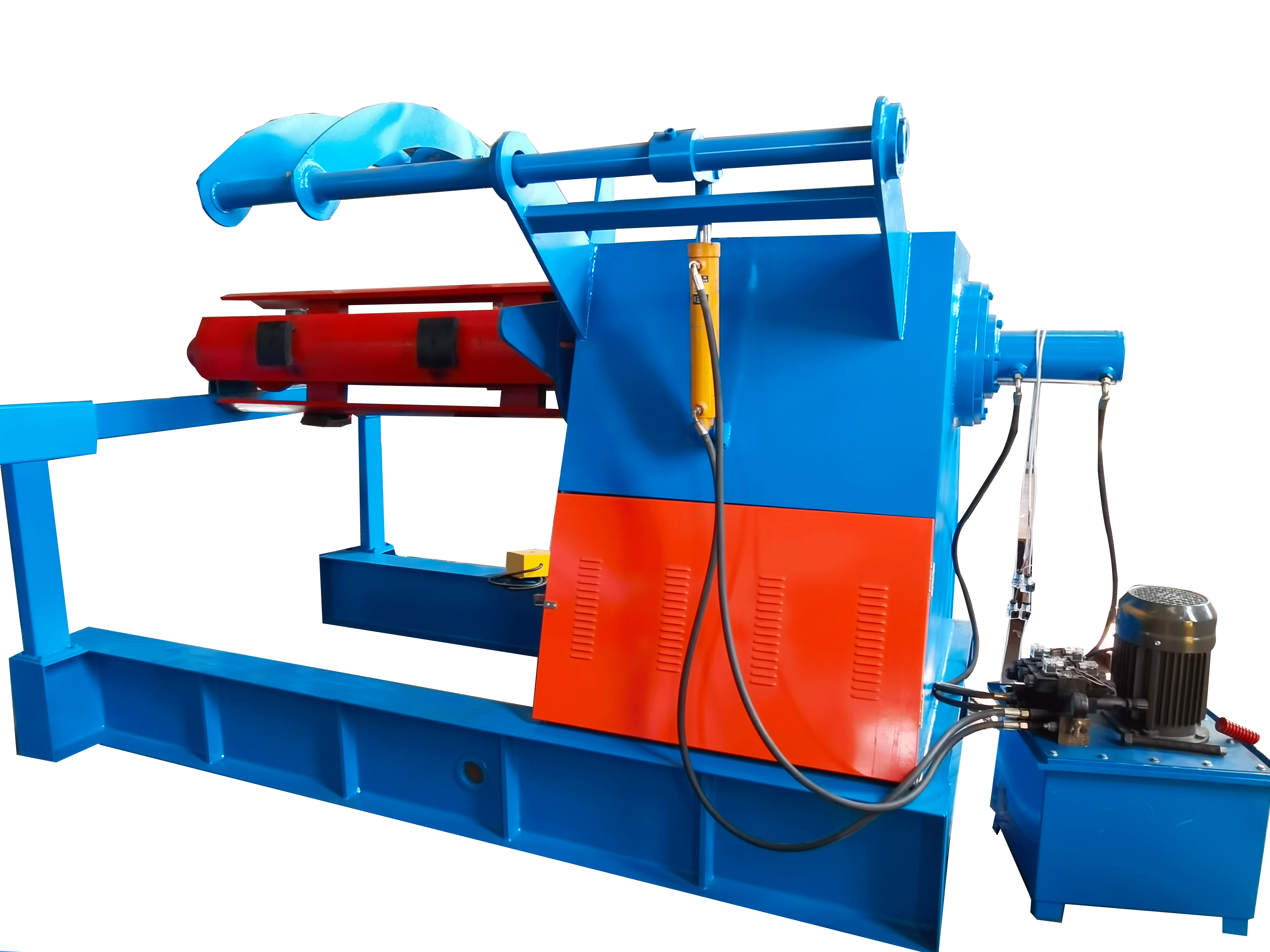

15 tons Hydraulic decoiler with car:

1. Active un-coiler: active to uncoiling.

2. Capacity of un-coiler: 15 tons

3. Width of steel coil: 1600mm

4. Inner diameter of steel coil: 508-630mm;

Outer diameter of steel coil: φ1600mm

5. Material of main shaft: 40Cr

6. Decoiler motor:11kw

7. Hydraulic motor power: 4kw

8. Uncoiling speed: 10-50m/min

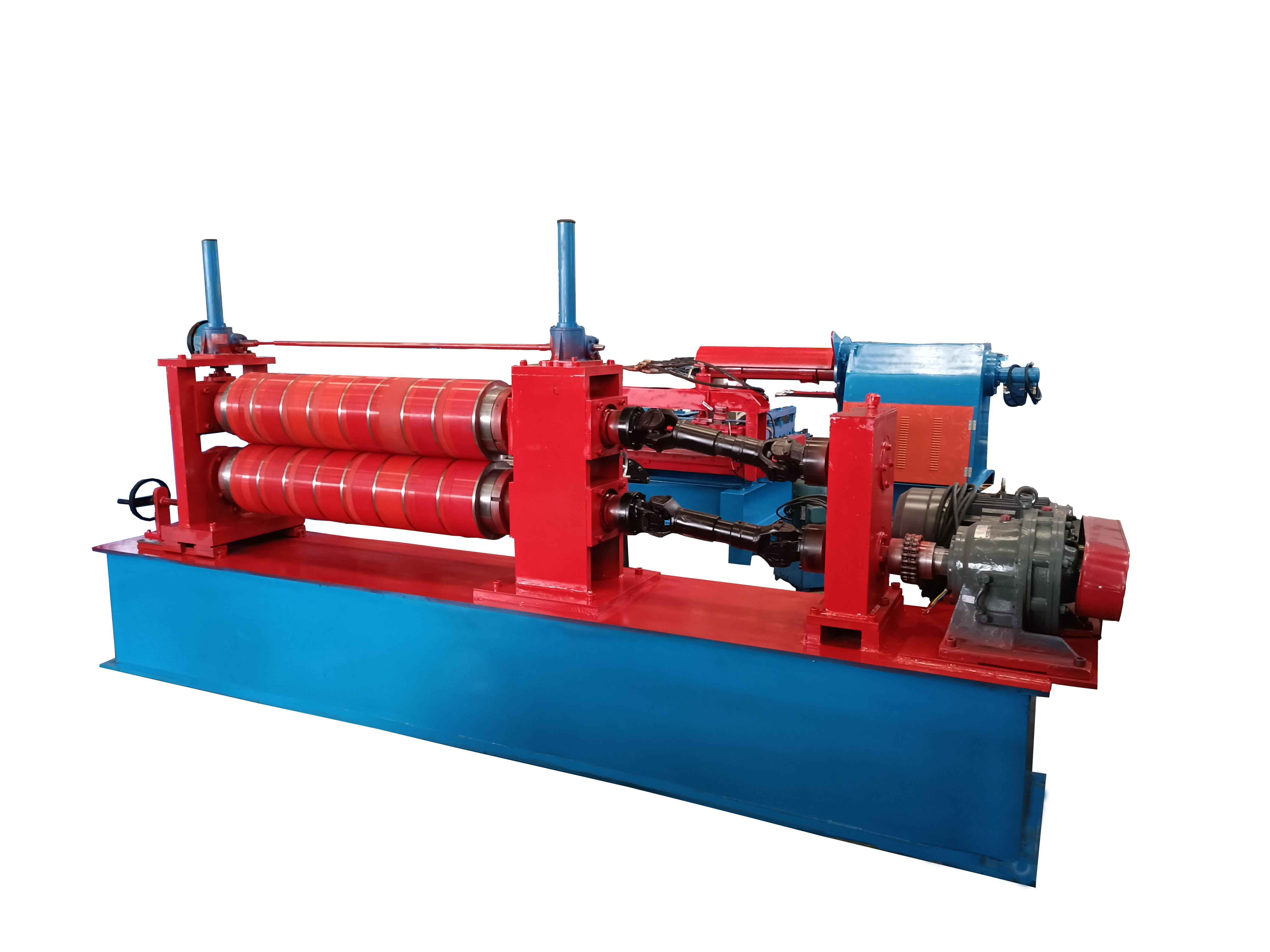

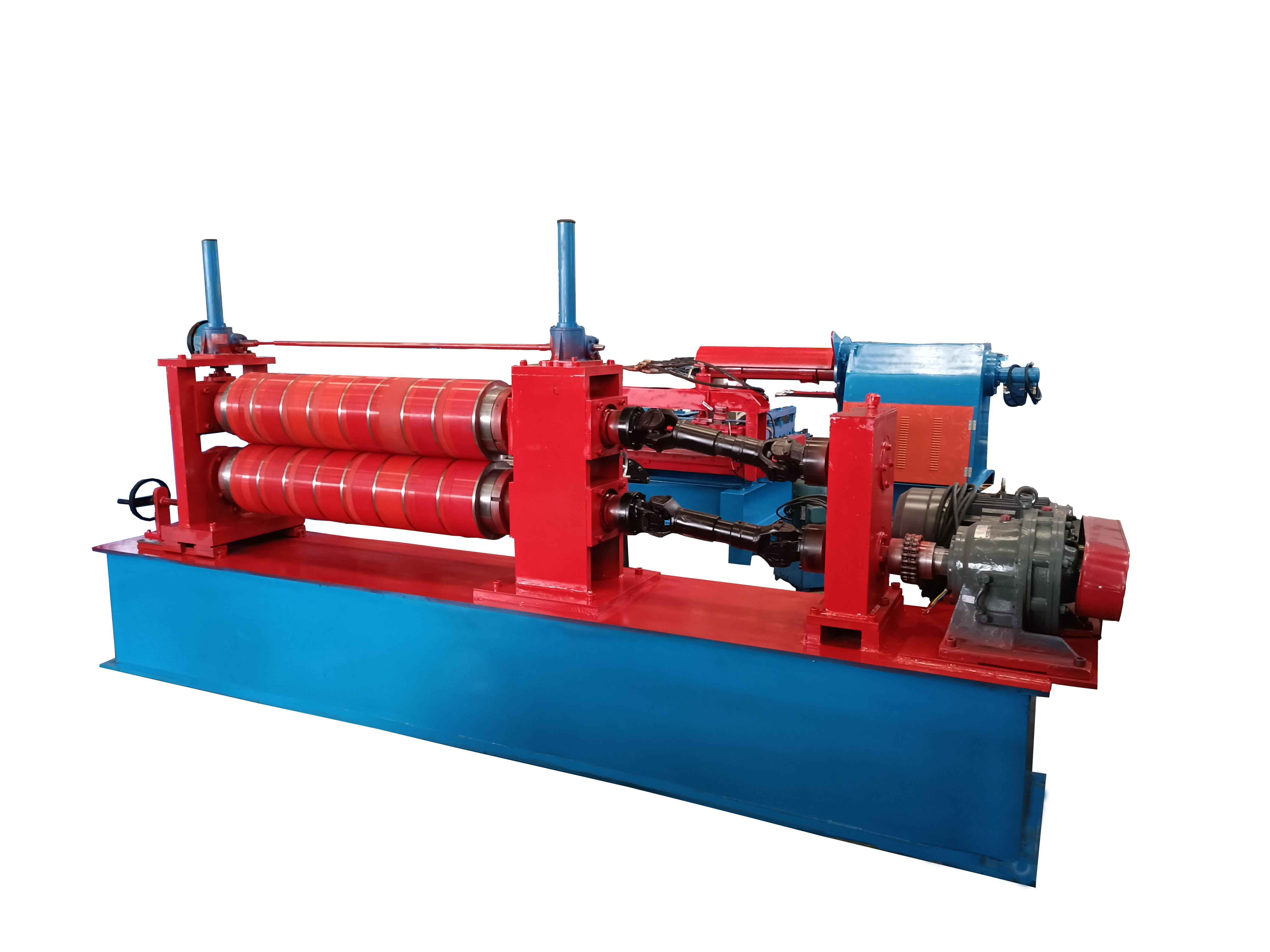

Flattening -slitting

1. Coil material: Galvanized sheet, PPGI, GI

2. Thickness of material: 0.3-3.0mm;

3. Width of material:1600mm;

4. Slitting speed:10-50m/min;

5. Slitting width tolerance: ±0.1mm

6. Work pressure of hydraulic system: 12Mpa;

7. Diameter of shaft:200mm

8. Minimum width:20mm

9. Power of slitting:30kw

10. Material of blade:6CrW2Si

11. Size of blade:280*200*10mm

12. Diameter of shaft:200mm

13. Material of shaft:40Cr

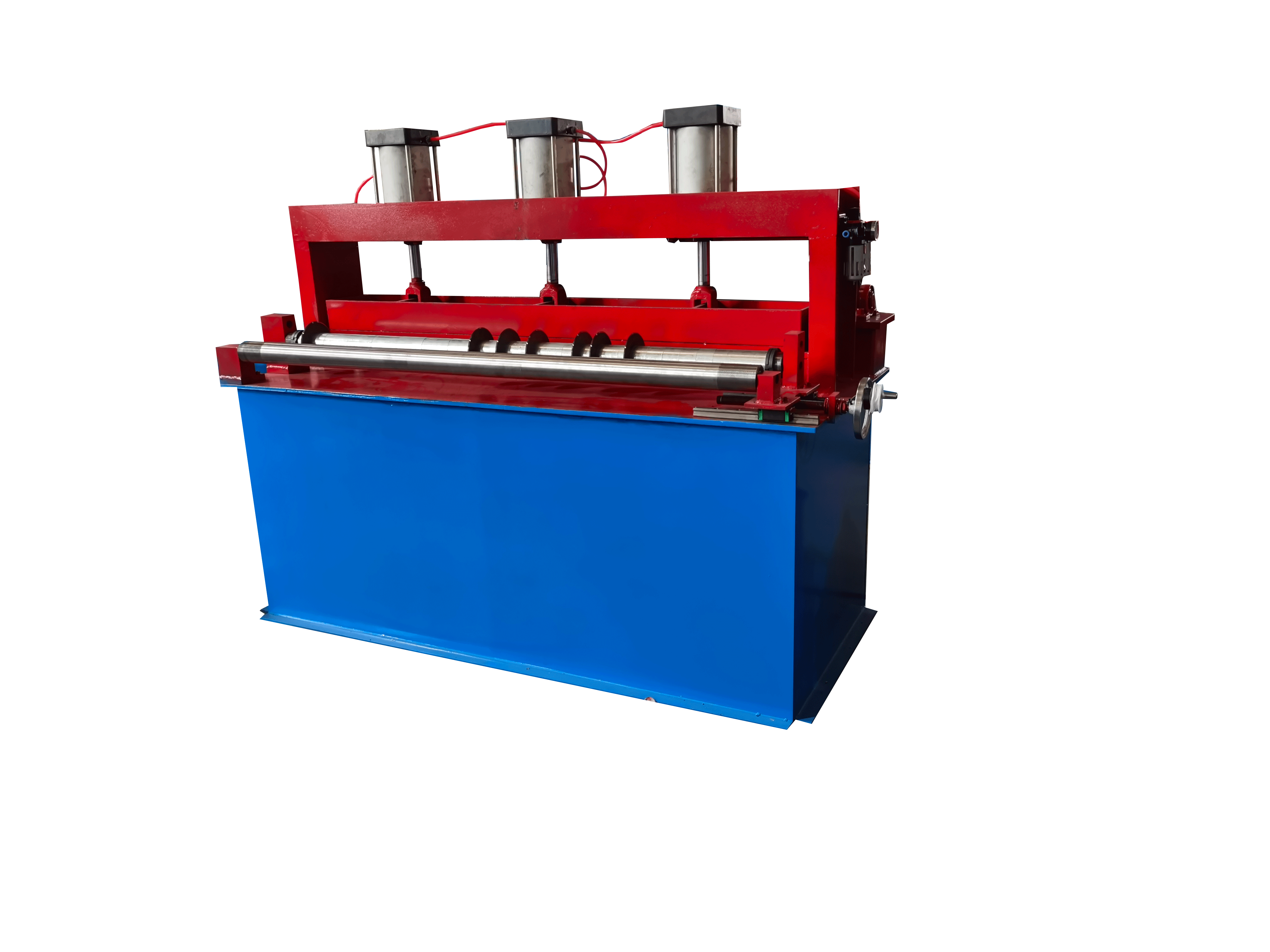

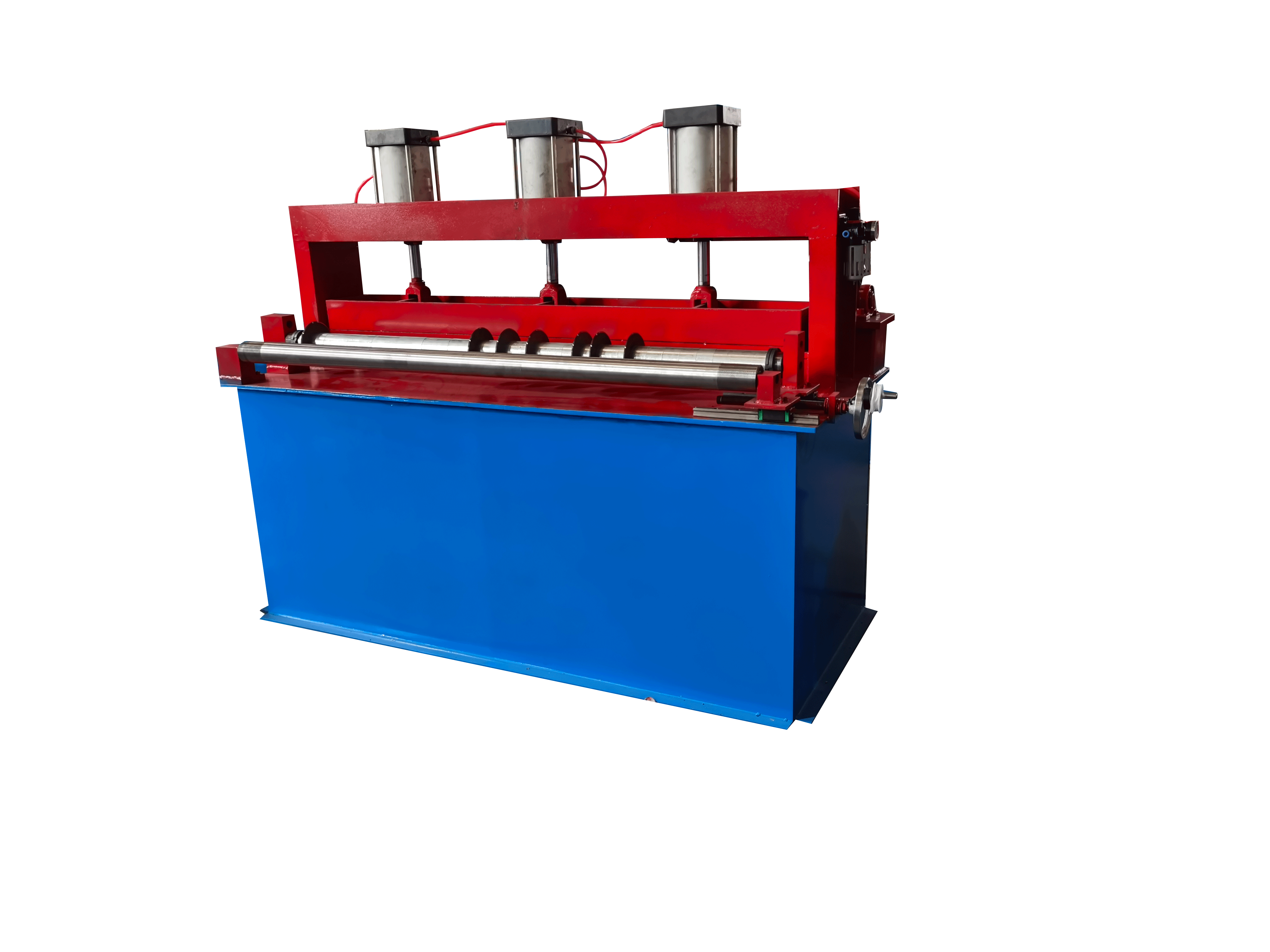

Tension unit & Scrap Winding:

15 tons with car hydraulic recoiler with pressing arm

1. Active re-coiler: active to recoiling.

2. Capacity of un-coiler:15 tons

3. Width of steel coil: 1600mm

4. Inner diameter of steel coil: 508-610mm;

Outer diameter of steel coil: φ1600mm

5. Material of main shaft: 40Cr

6. Recoiler motoe power:45kw

6. Hydraulic motor power: 4kw

7. Pneumatic damp pressing arm

8. Recoiling speed: 10-50m/min

Advantage:

It emerged as an efficient alternative to time-consuming and labor-intensive methods of slitting metal, such as band saws or cut-to-length operations. With high-speed steel-slitting lines, steel suppliers can process more material faster and supply slit coils and sheets more cost-effectively.