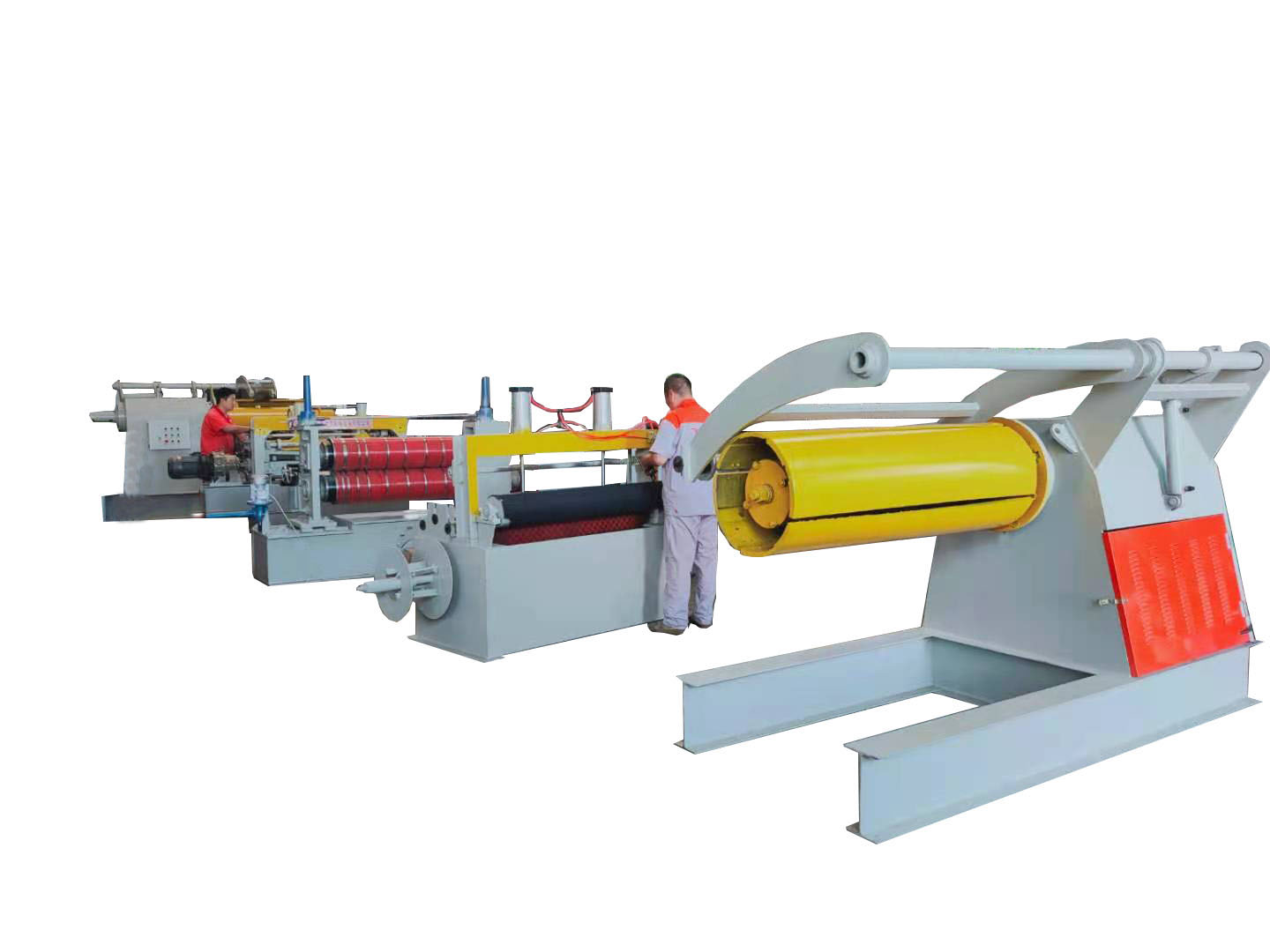

High Speed Metal Coil Stripe Steel Sheet Cutting And Slitting Line Machine

No. | Model | Delivery time | Package | Qty |

1 | 0.3-3.0MM High Speed Slitting line | 50 working days | 40GP container | 1 set |

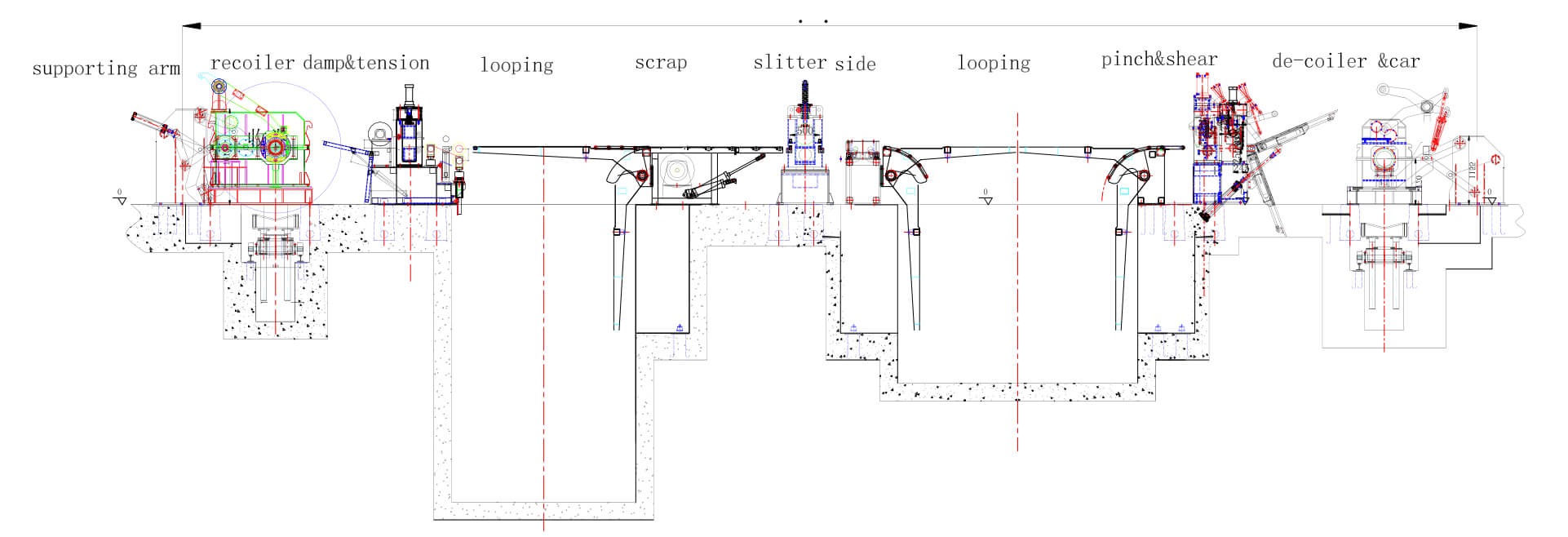

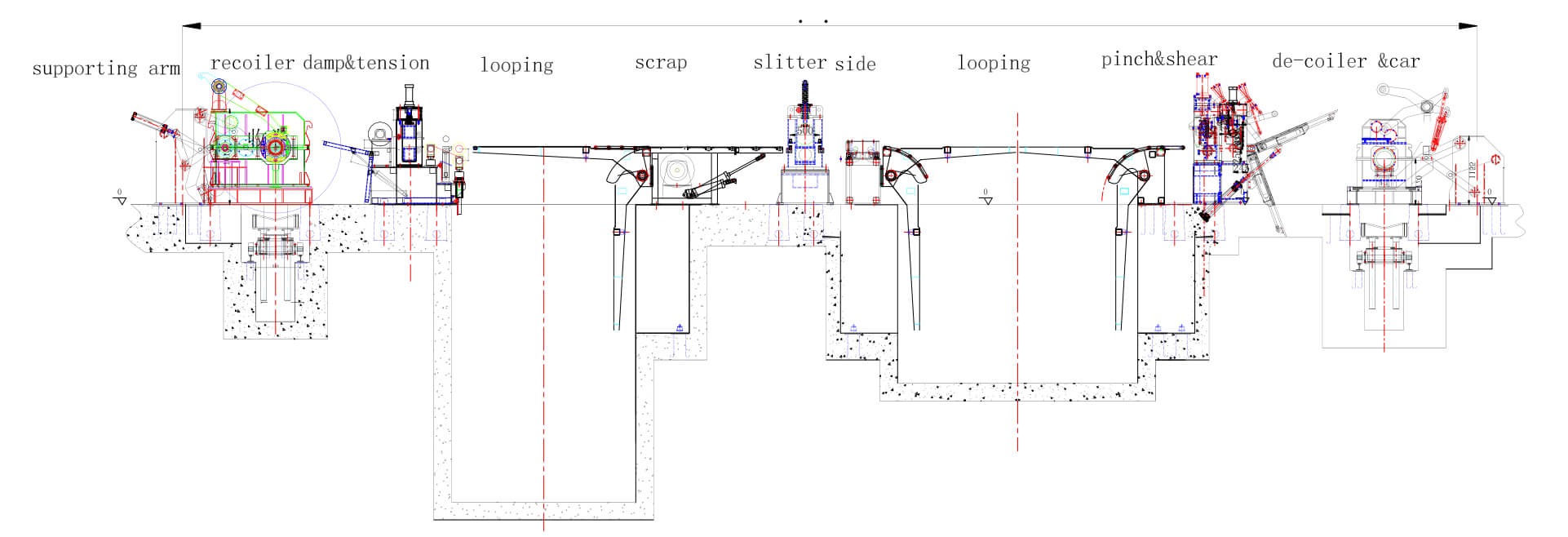

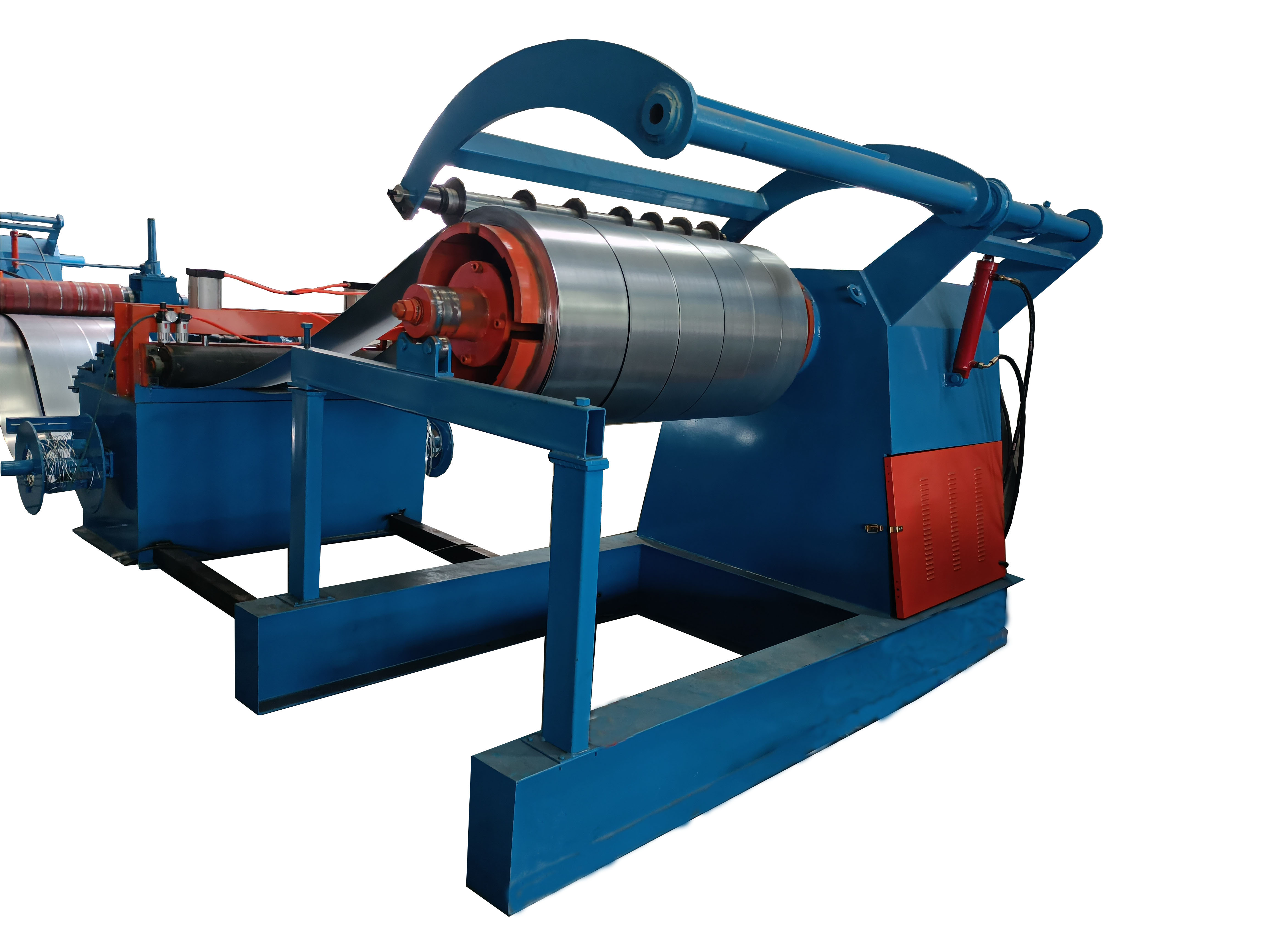

Working Flow:

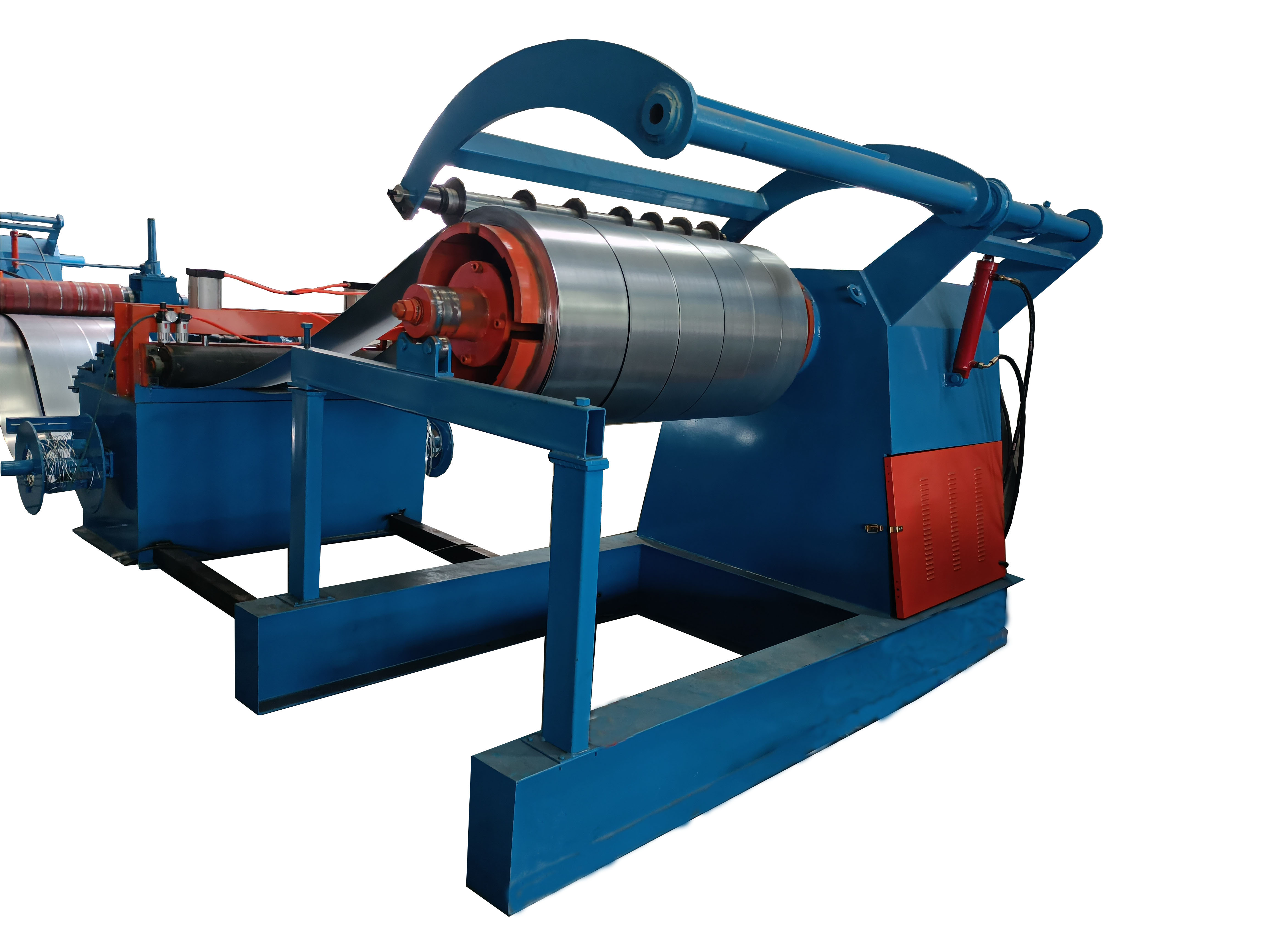

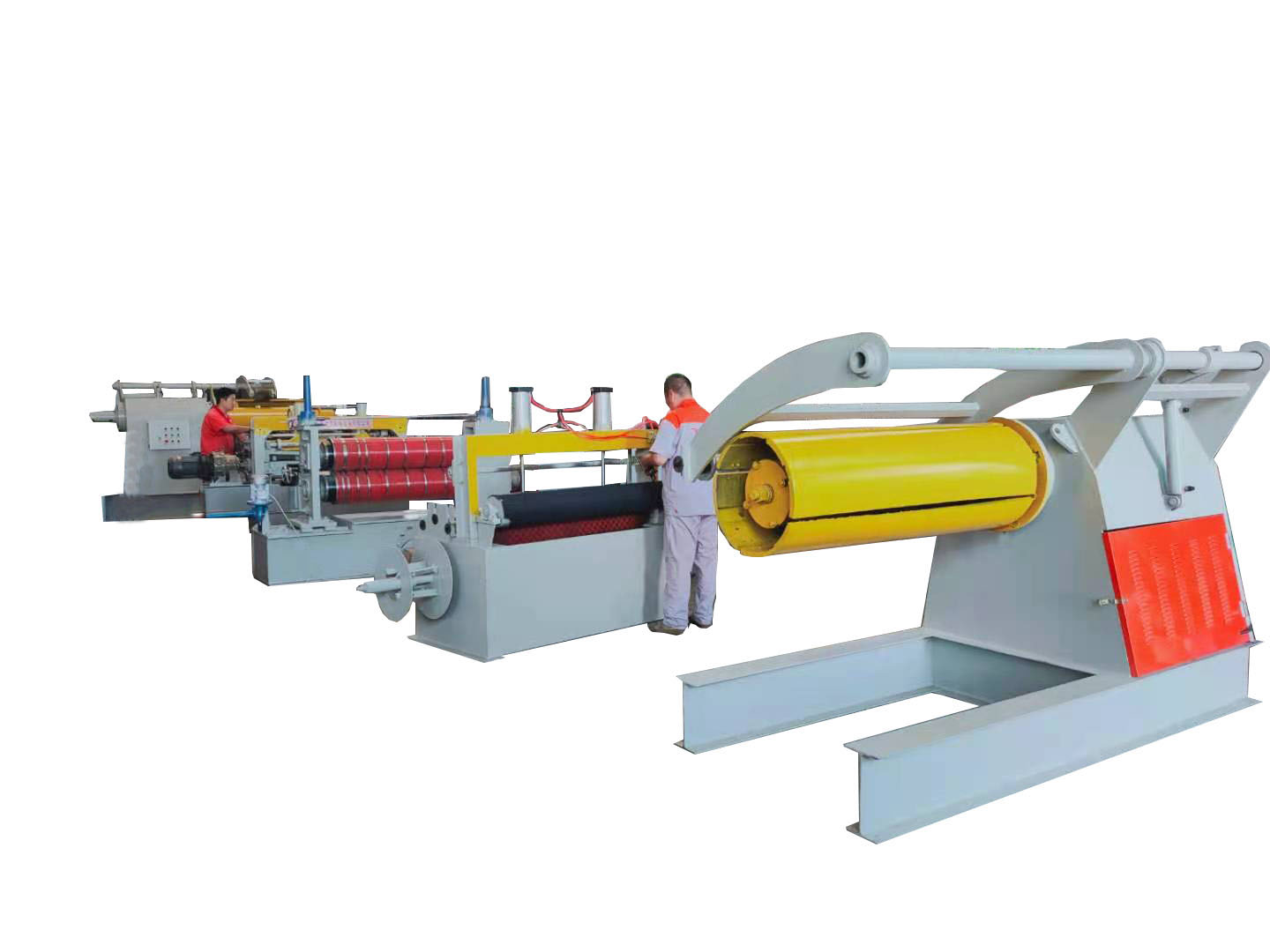

Hydraulic decoiling → Feeding sheet and Flattening sheet → Slitting sheet→ Scrap Winding→ Tighten the roll→ Hydraulic recoiler

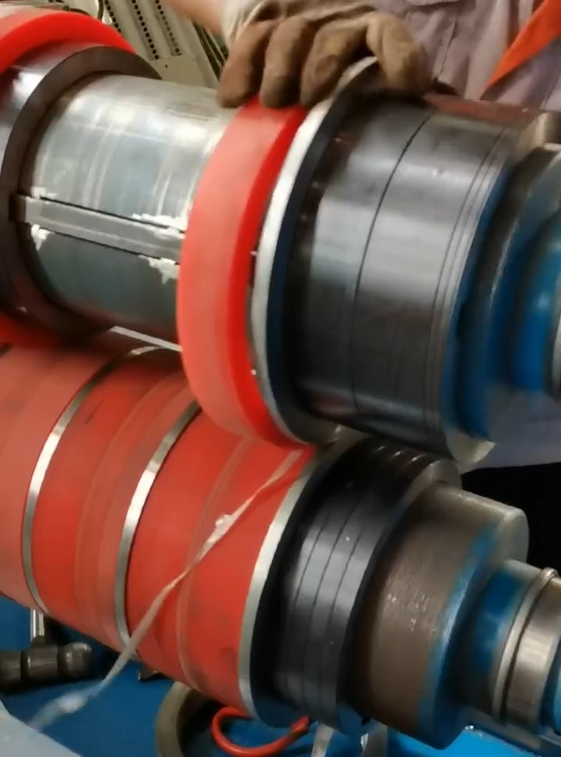

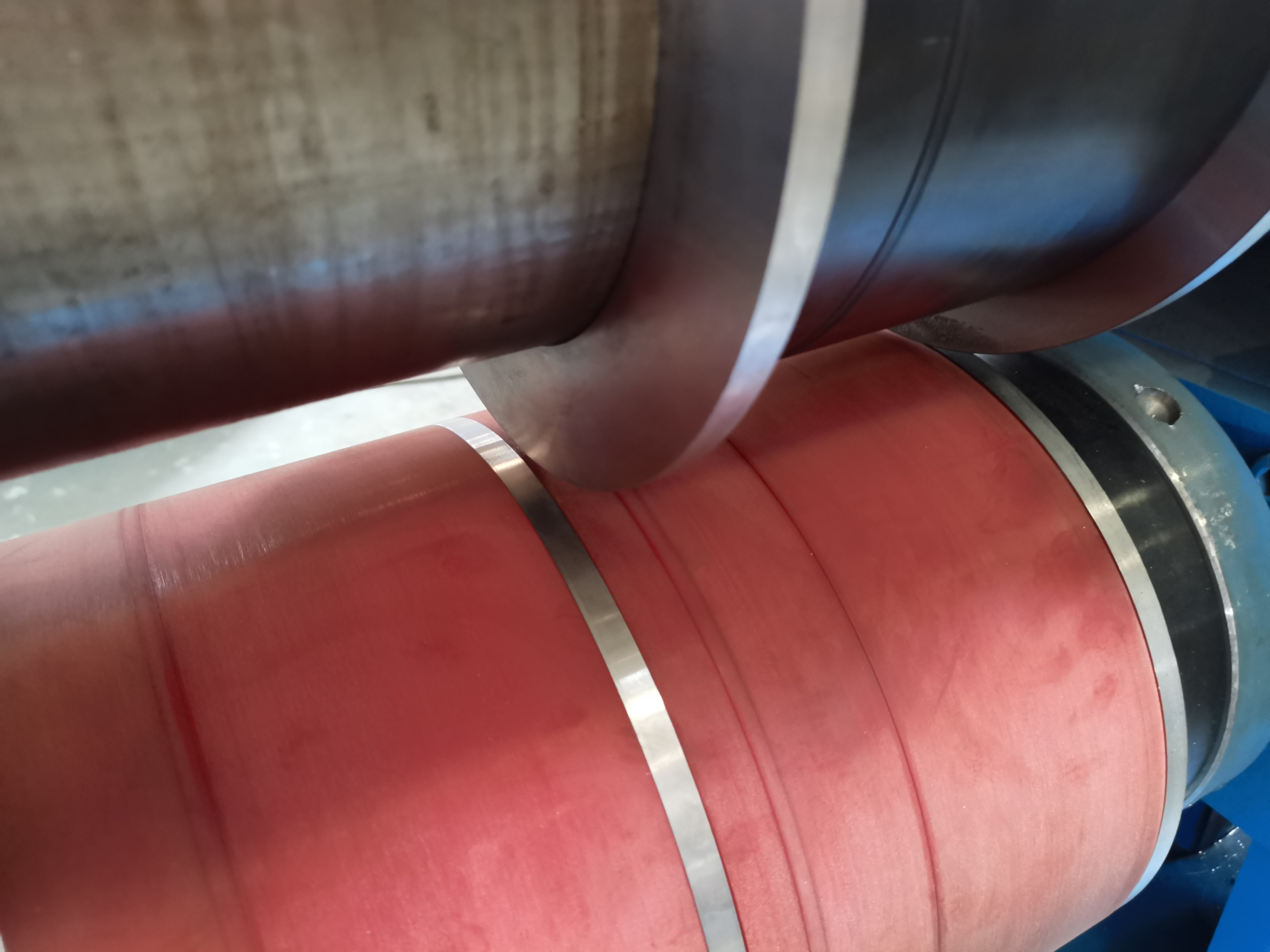

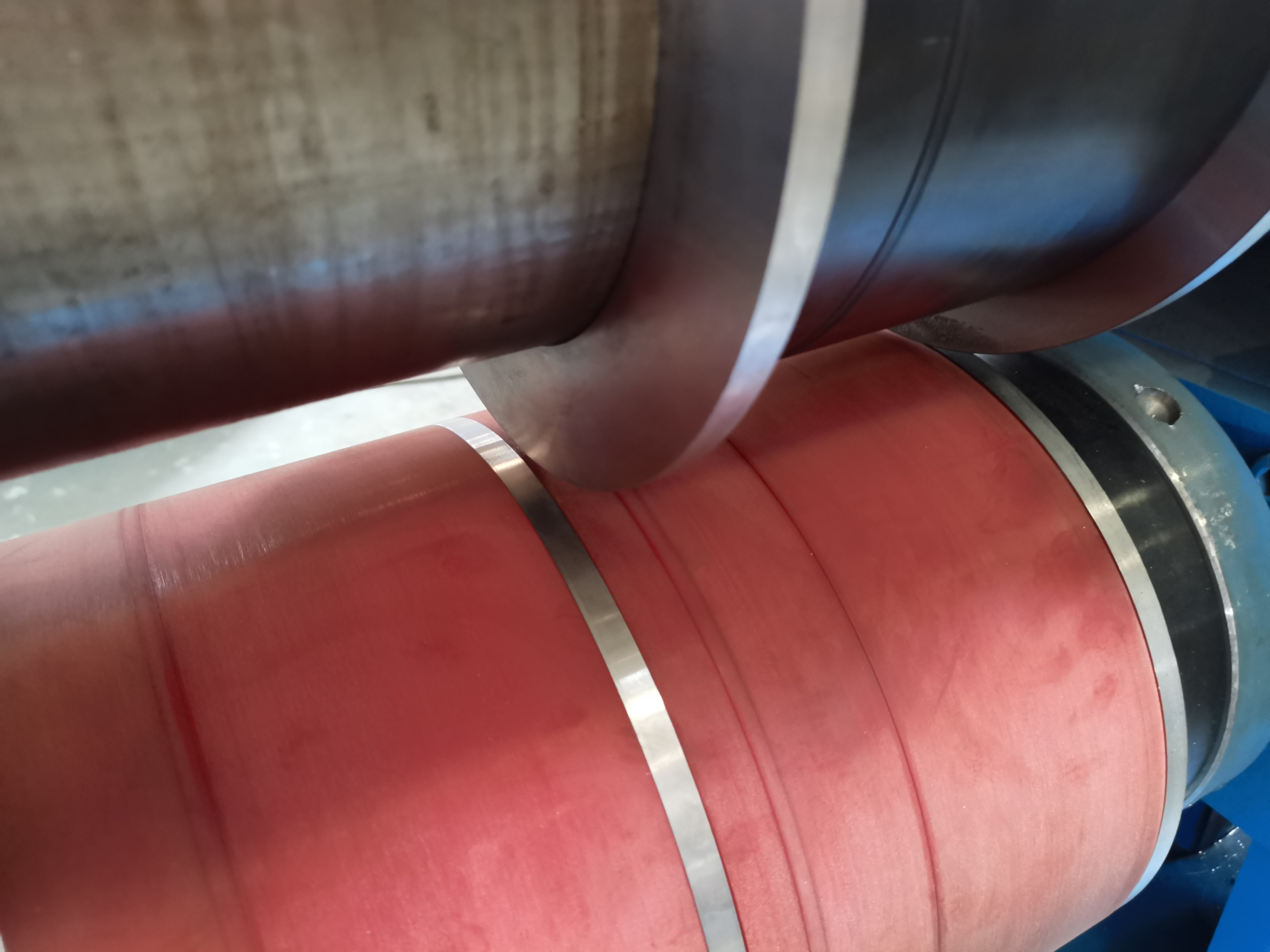

How to adjust width of stripe?

It is manual way to adjusting different width of stripe, we will prepare different size rubber spaces,added together, you can get the desired size.

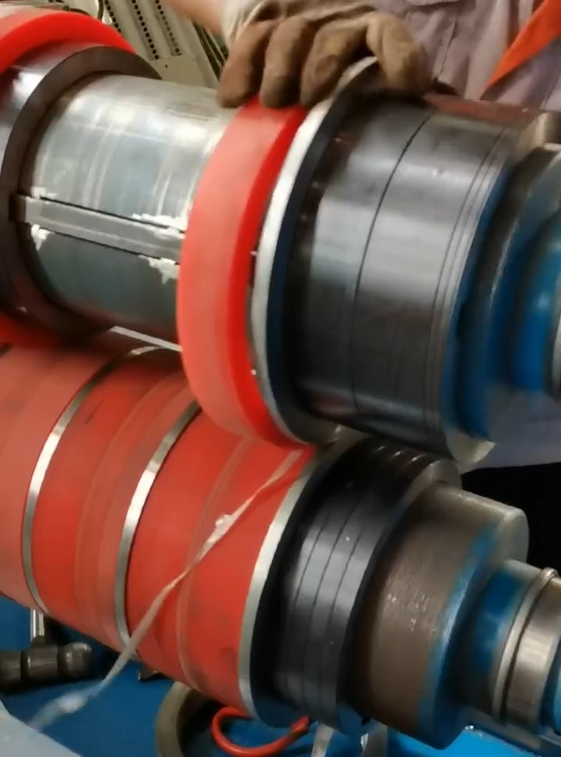

Blade material is SKD11 with high precision process, it is can keep long time working lift, and it is can do shape again after long time working.

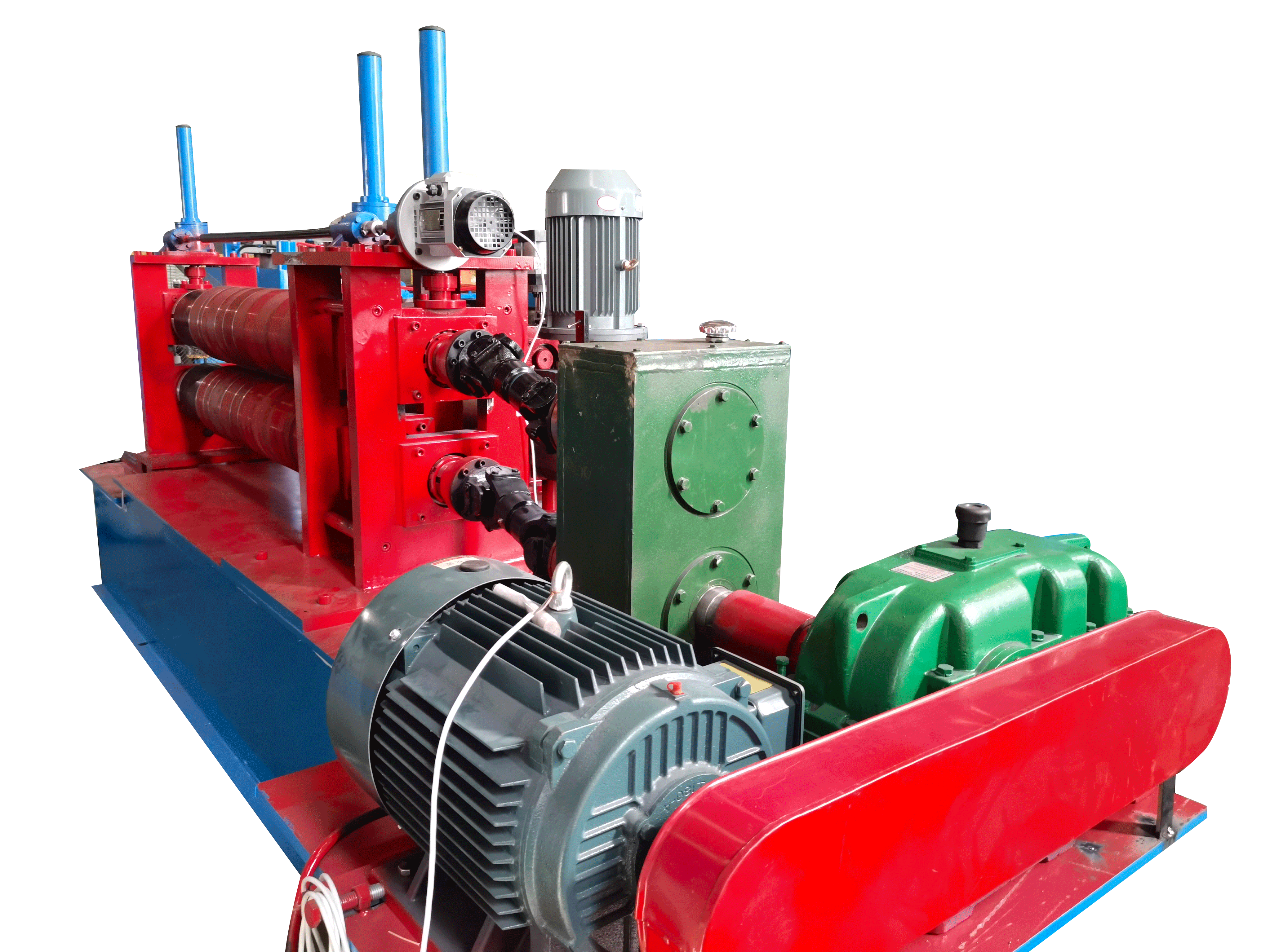

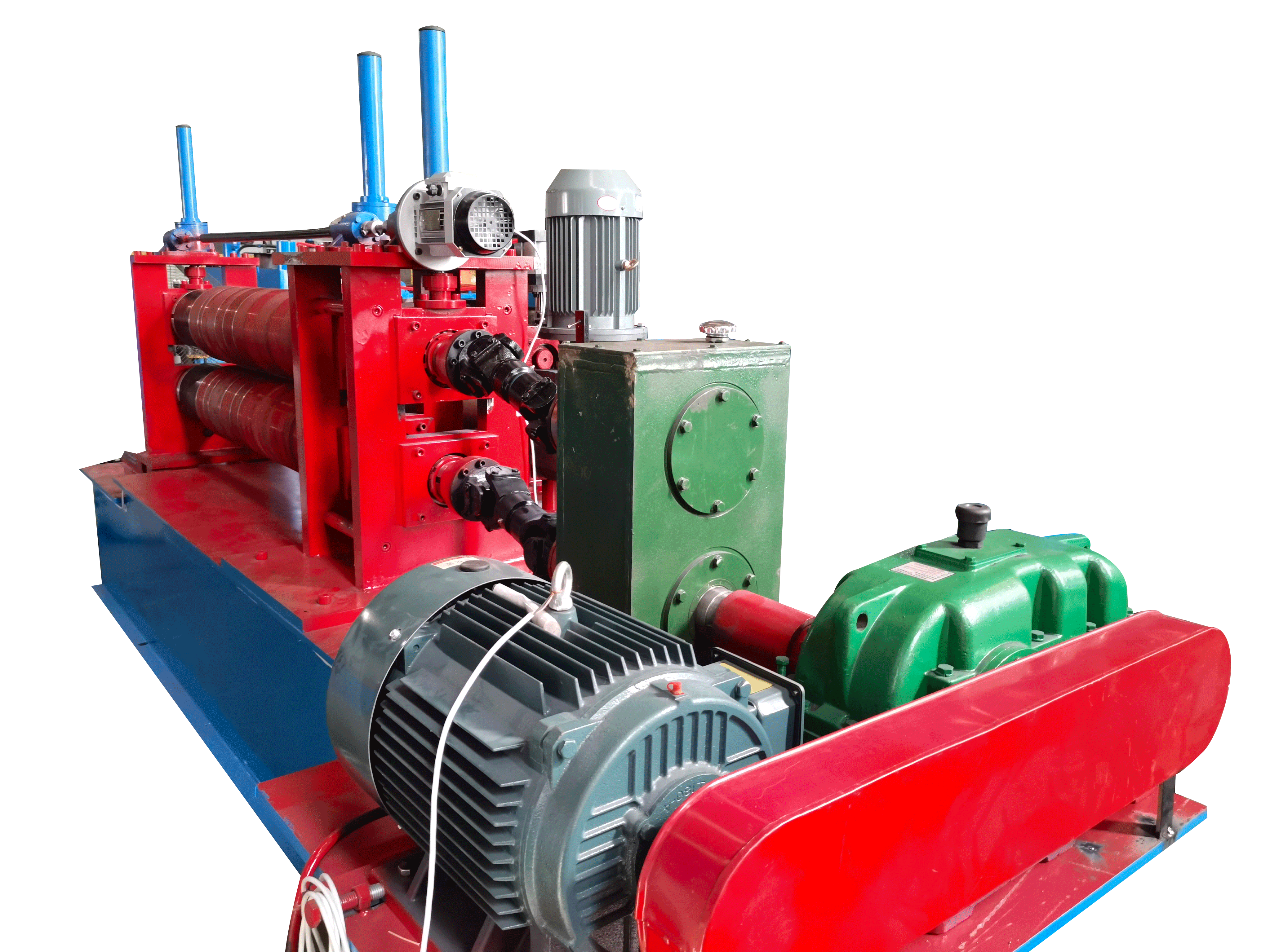

We use gearbox driven for slitting line, it is working in powerful.

1. Coil material: Galvanized sheet, PPGI, GI

2. Thickness of material: 0.3-3.0mm;

3. Width of material:1600mm;

4. Slitting speed:10-50m/min;

5. Slitting width tolerance: ±0.1mm

6. Work pressure of hydraulic system: 12Mpa;

7. Diameter of shaft:200mm

8. Minimum width:20mm

9. Power of slitting:30kw

10. Material of blade:6CrW2Si

11. Size of blade:280*200*10mm

12. Diameter of shaft:200mm

13. Material of shaft:40Cr

We can match leveling and cross cutting machine for slitting line. PLC can control slitting how many meters of coil.

Tension unit & Scrap Winding:

It is pneumatic control the working, it is must be keep stripe tighten after slitting and before recoiling, then we can get all rolls in correct.

Slitting line working speed is 30m/min, it is normal speed and good price,and one line can match with several light gauge steel roll forming machines, customers always purchse by this way.

Service :

We provide 24-hour online service for our customers.

(1) The seller will test the machines freely in China, and the traffic expense in

China of the technique people will be paid by the seller. When our engineer goes to the buyer's place to test the machines, the buyer should pay the expense of accommodation, and traffic for the buyer's engineer.

(2) If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's engineer, as well as daily salary of USD 150.

Warranty:

Two years, during which all parts damaged because of the quality problem will be changed for free, but not include damage caused by natural disaster or inappropriate operation or human factor.

FAQ:

How to place an order?

Inquiry---Confirm the profile drawings and price----confirm the PI---Arrange the deposit or L/C---Start design and production--- Test and inspection --- Pay the balance --- Arrange shipping

What's your delivery time?

Within 60 days after receiving prepaid. Some machines are in stock, so can be delivered at any time.