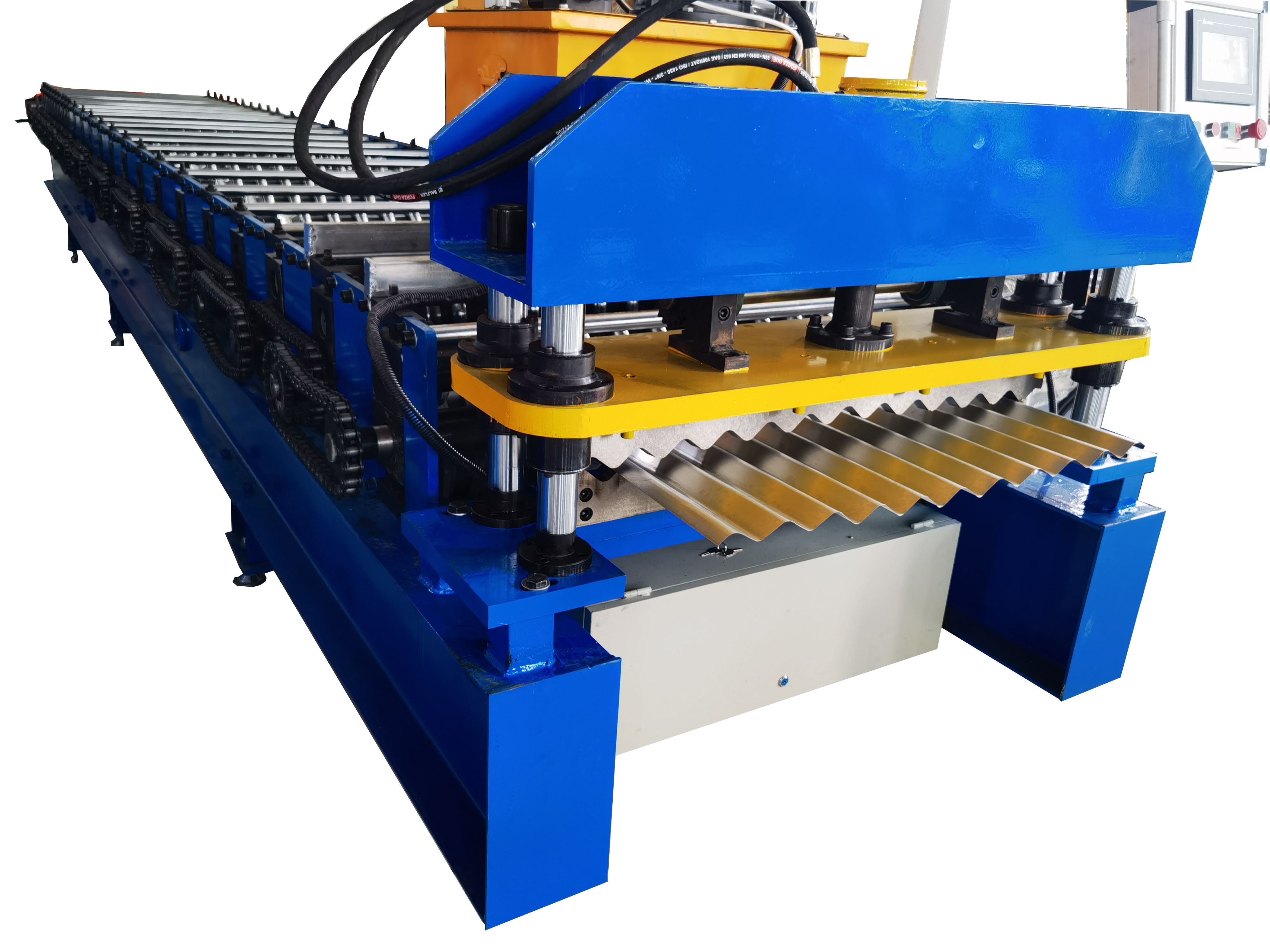

Metal Panel Roofing Tile Corrugated Sheet Making Roll Forming Machine

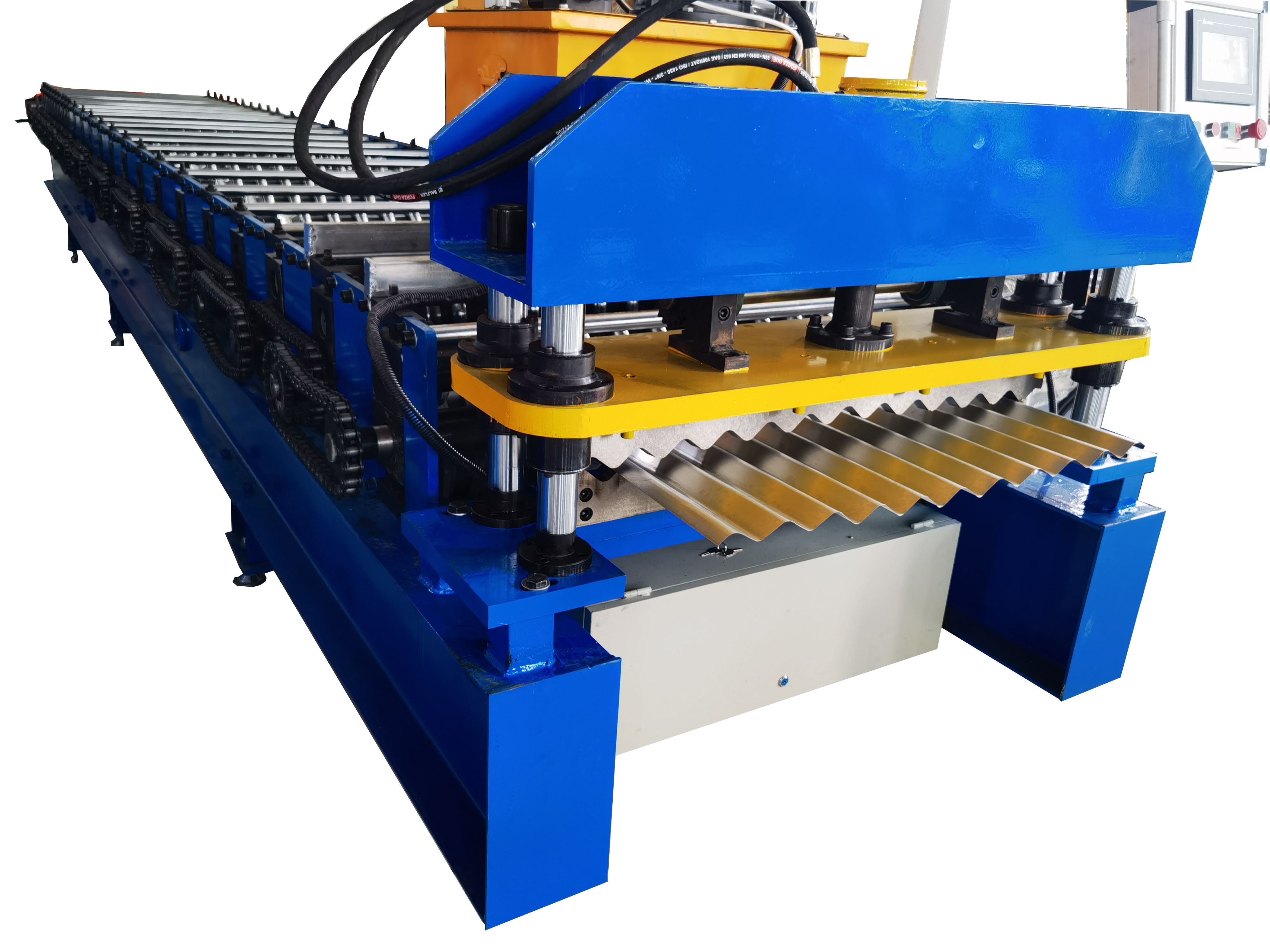

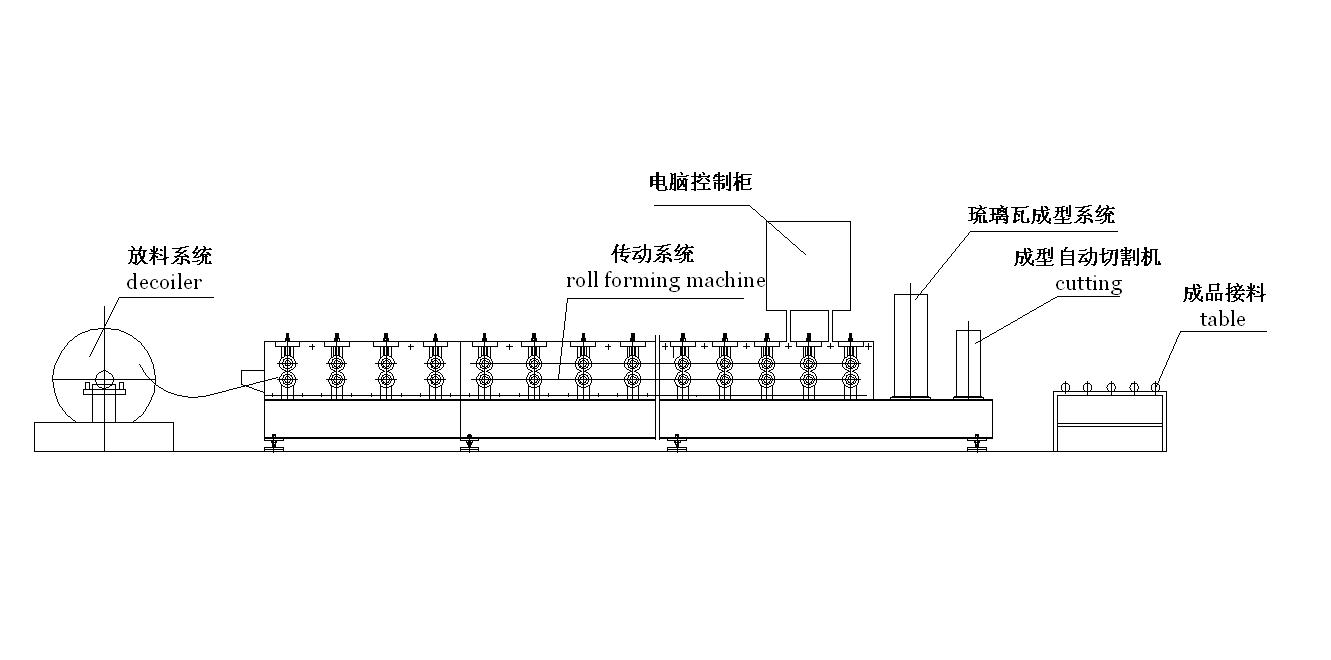

Our corrugated sheet machine consists of decoiler, feeding and levelling device, pre-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system).

Produce standard products with yield strength up to 450Mpa,Long production line, good profile shape on final products; Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision.

Equipment:

- Automatic roll forming and cutting with Inverter,PLC, HMI

- Automatic programmable length settings via the touch panel

- Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

- Electrical and hydraulic components made from Japan, Germany Save history for orders in 30 days

- Customize design

-Stable operation with strong power and body frame

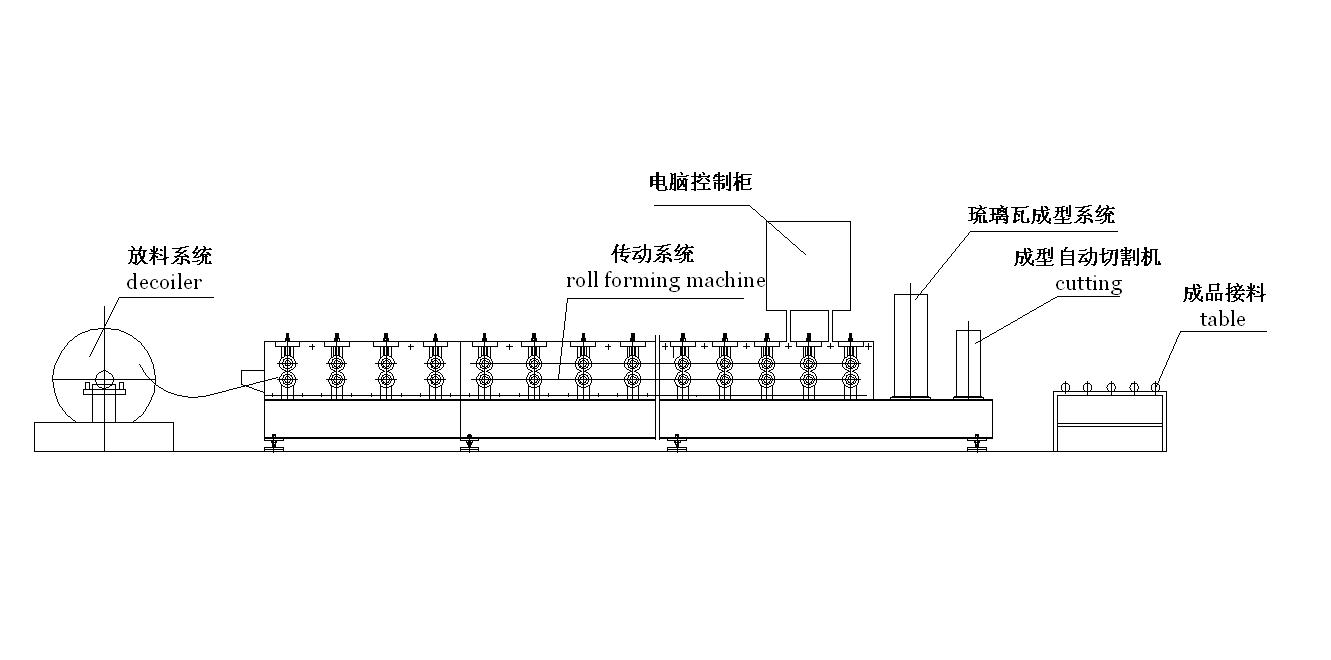

Working Flow:

Uncoiler---Entry Beach---Roll Forming Machine----Automatic Shearing Service---Computer Control Cabinet---Run-out Tables

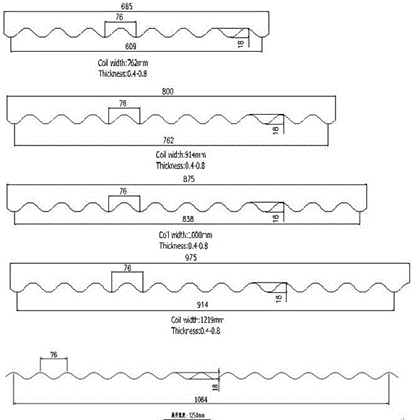

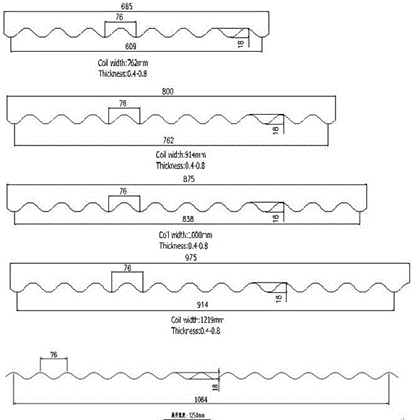

Specification:

No. | Item | Unit |

|

| Corrugated Roll Forming Machine |

1. | Steel grade of main frame |

| 16mm steel plate |

2. | Profile Type |

| As drawing or sample |

3. | Feed coil Thickness | mm | 0.3-0.7 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 70 |

7. | Roll Station | No. | 16 |

8. | Dimension | m | 8*1.4*1.2 |

9. | Weight | Tons | 3.5 |

10. | Rolling material |

| 45# Steel,hard treatment and chorme coating |

11. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

12. | Line Speed | m/min | 0-40 |

13. | Drive Type of Roll Forming Machine |

| Drive by Chain |

14. | Power of Main Motor | kw | 5.5,380V,50HZ,3phase |

15. | Oil Pump of Hydraulic Station |

| With fan |

Cutting Machine |

16. | Type |

| PLC controlled Hydraulic Cutting |

17. | Thickness capacity | mm | 0.3-0.7 |

18. | Width capacity | mm | As drawing |

19. | Cutting blade steel grade |

| Cr12, quenching |

20. | Hardness |

| 58-62 HRC |

21. | Cutting tolerance | mm | +/- 2 |

22. | Power | kw | 4,380V,50HZ,3phases |

Control Unit |

23. | Type |

| PLC controlled |

24. | PLC brand |

| Delta |

25. | Encoder |

| Omron |

You can customize different color and design:

Use:

Corrugated roofing sheets are some of the most common means of waterproofing for garages, sheds, carports, and larger agricultural buildings. Beyond being one of the easiest forms of roofing to install, these sheets tend to be far stronger, more lightweight, and longer-lasting than most alternatives.

Service And Warranty:

1.After-sales service team:

We have a professional after-sales service team. If our engineers cannot come to your factory to debug the machine due to some circumstances, the engineer and I will solve the after-sales problems for you through phone and video, and quickly return the machine to production.

2.Warranty:

18 Months,spare parts breakdown,please send us the old parts,we will send new parts to you for free.