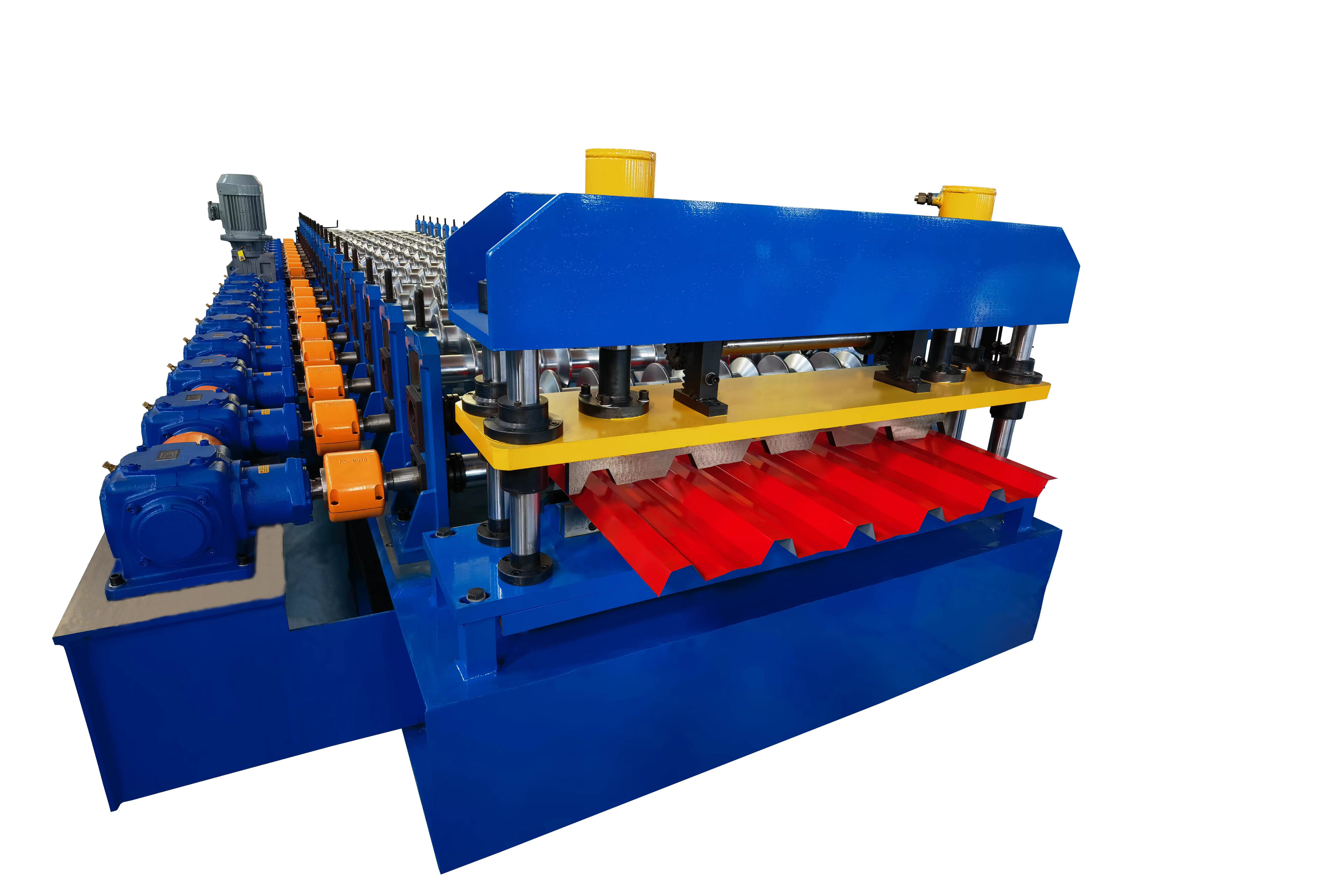

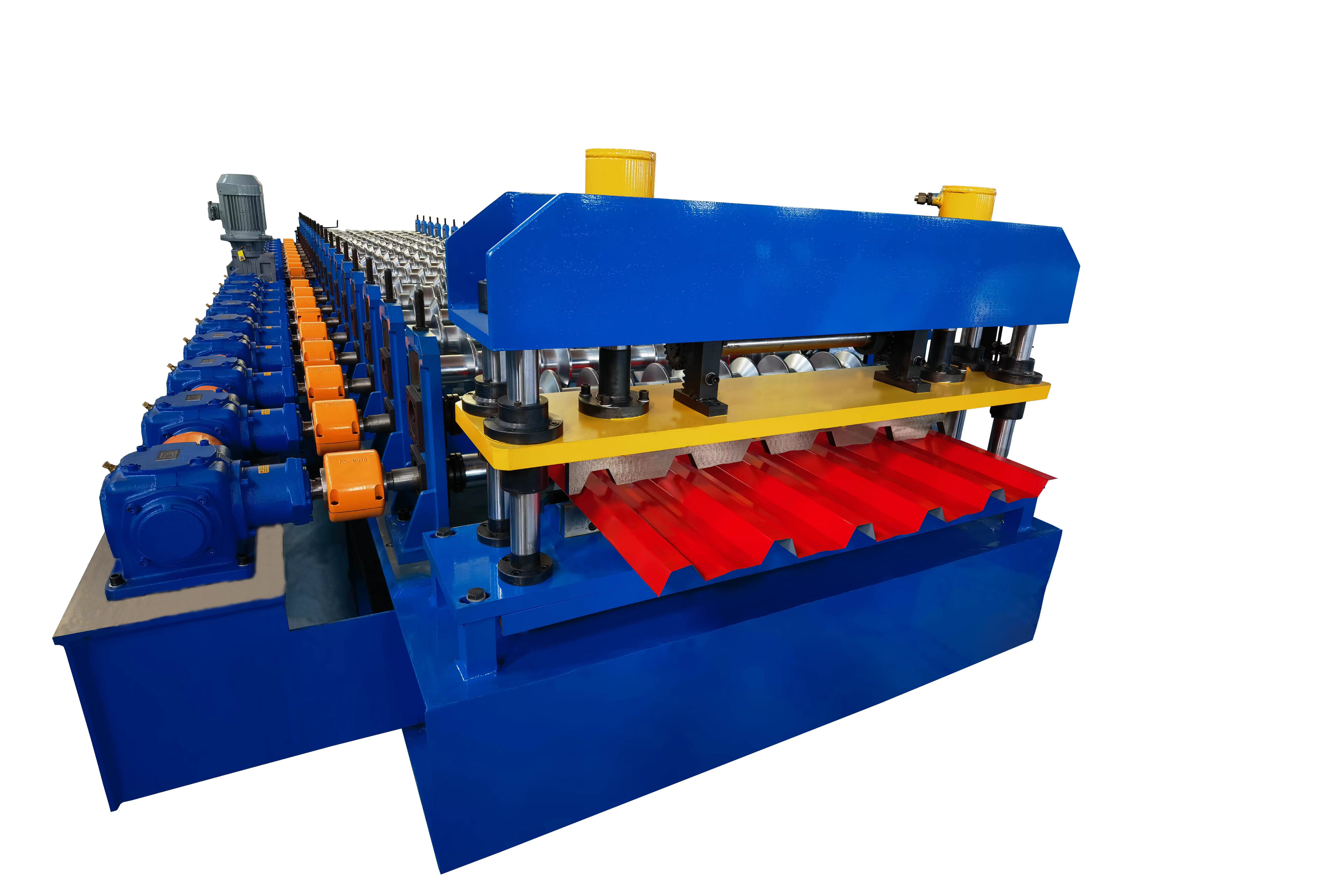

RIB Panel Roofing Sheet Roll Forming Machine

Roof panels are used in the building materials industry and can be used as roof and wall decoration. Roof panels are divided into trapezoidal shapes, corrugated shapes, and glazed tile shapes. Roofing Sheet Roll Forming Machine is customized follow with customer's requirement, this machine is includes decoiler, feeder, roll forming,PLC,Hydraulic Cutting System and Table.

Product Advantage:

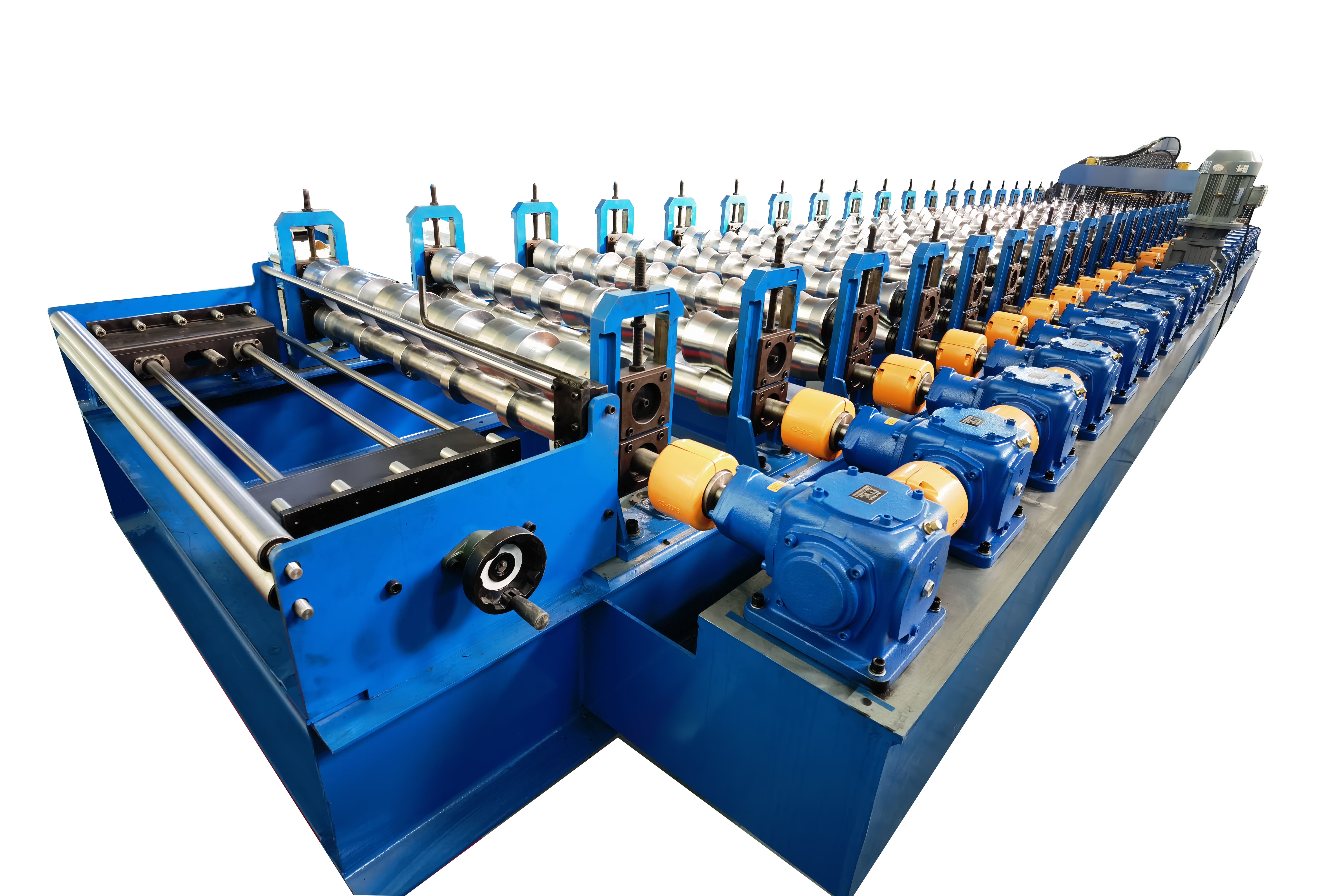

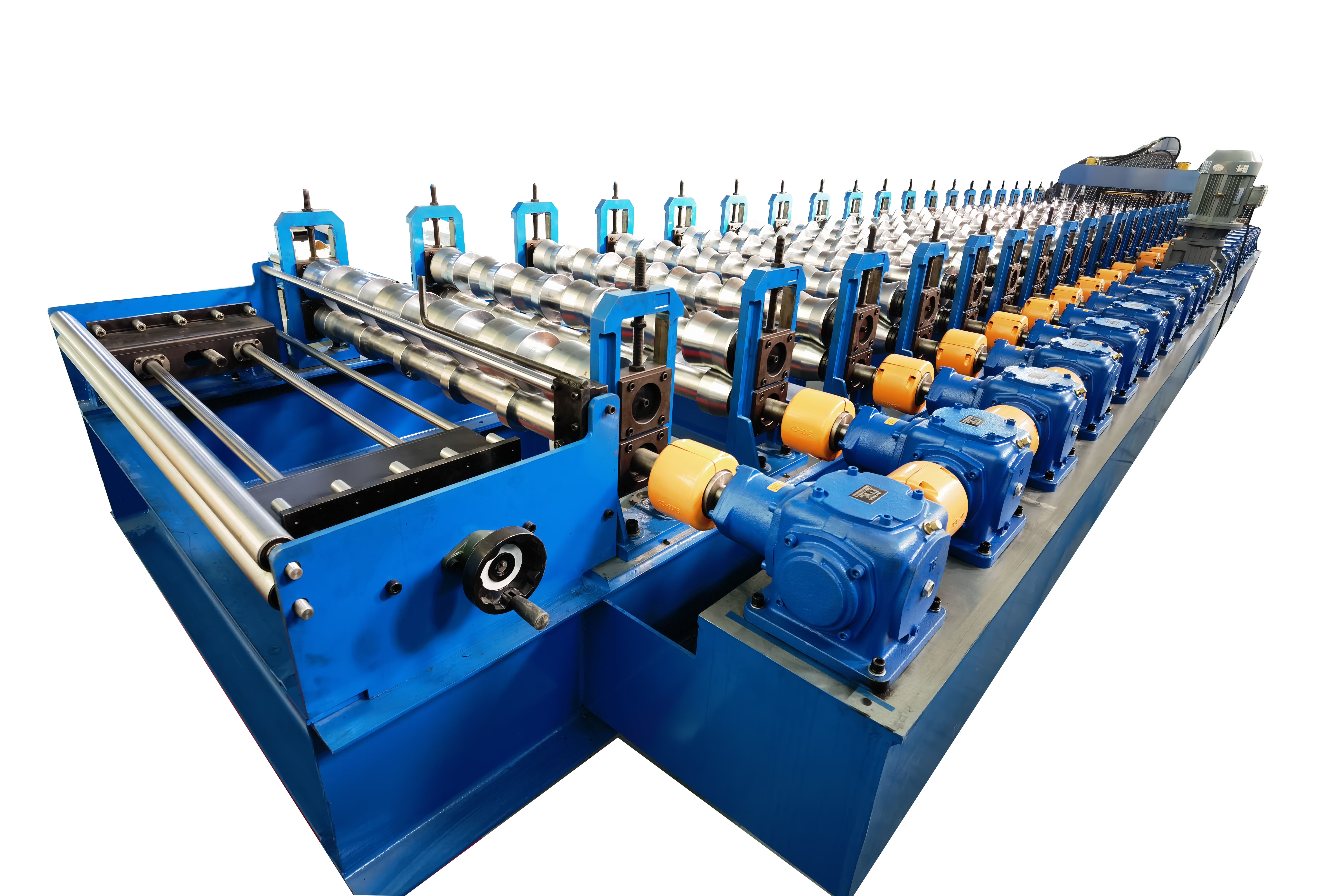

1.Our engineer has more than 20 years experience in design rollers,so we can make sure all design roll forming in perfect.

2.All rollers and shafts processed by CNC machines,it is can keep high precesion.

3.We pay all attention to detail of machine and make all parts working well and look nice.

Specification:

| Items | Roofing Sheet Roll Forming Machine |

| Total power | 4kw-5.5kw(3 phase,50 hz /60ha,380v/220v/230v/440v) |

| Speed | 0-25m/min |

| Dimension(L*W*H) | 8.5m*1.4m*1.6m |

| Weight | 3.5 tons |

| Roller station | 18 pairs |

| Frame | Cast frame+tube/steel box/ Steel plate+ 350H Steel |

| Material thickness | 0.3-0.6mm |

| Material width | Follow with design |

| Transmission system | Chain |

| Cutting system | Hydraulic cylinder(profile cutting system) Material SKD11 Japan |

| Control system | PLC,Xinjie/Delta |

| Runout table | Manual 3m,100kg load |

| Decoiler | Manual / Electrical,1.5 tons-7tons |

| Equipment |

| PLC | XINJIE/Delta(China) |

| Touch panel | XINJIE/Delta(China) |

| Electric motor | BOJIANG(China) |

| Encoder,relay | OMRON(Japan) |

| Hydraulic components | GUOWEI(China) |

| Cutting blades | SKD11(Japan) |

| Rollers | Cr12/GCr15/45#Steel |

FAQ:

1.Can you make the machine according to my design or prototype?

Yes, we have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

2.How can I trust you that machines pasted testing running before shipping?

1) We record the testing video for your reference

2) We welcome you visit us and test machine by yourself in our factory.