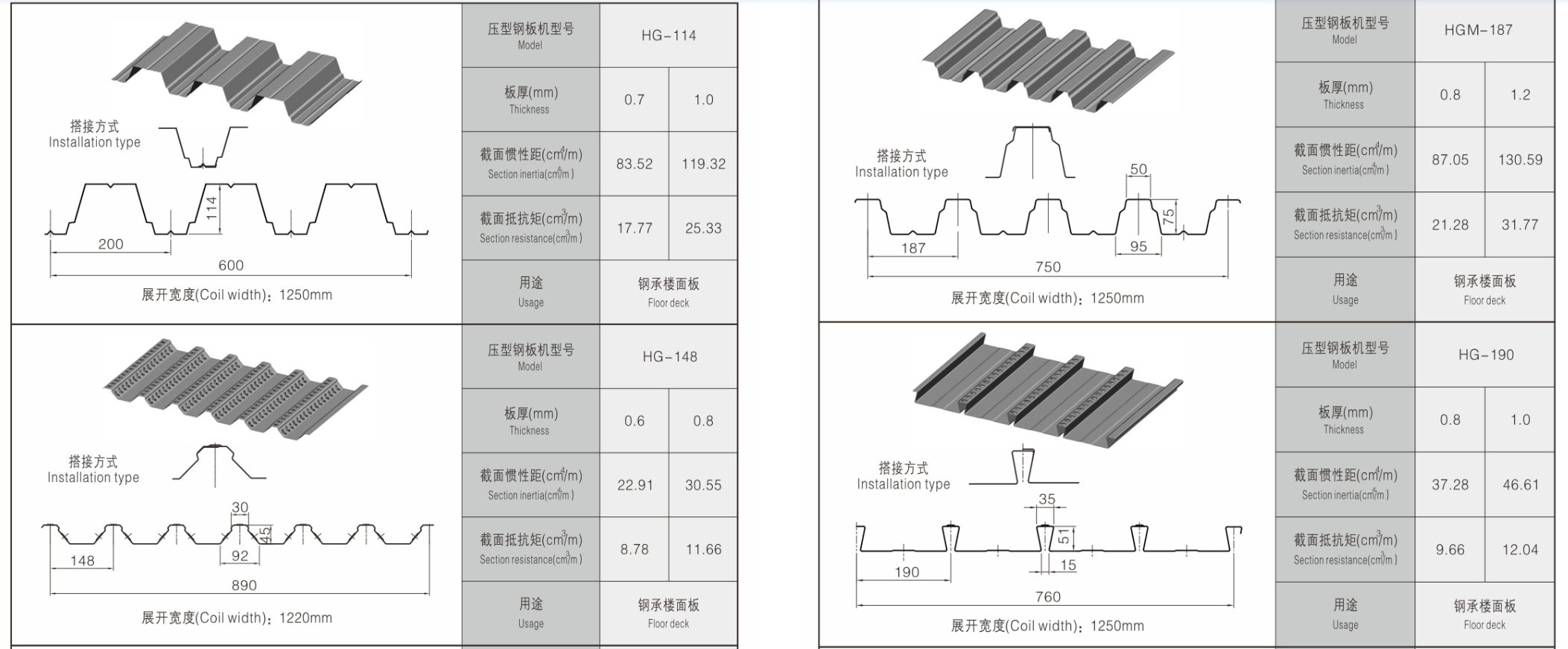

Metal Decking Steel Structure Cement Floor Deck Tile Cold Roll Forming Machine

The sheet produced by this floor deck steel roll forming machine has high strength with big wave length , and adheres well to concrete . Used on tall buildings ,our steel roll forming machine not only saves steel mold sheet, but also reduces the weight of the storey .

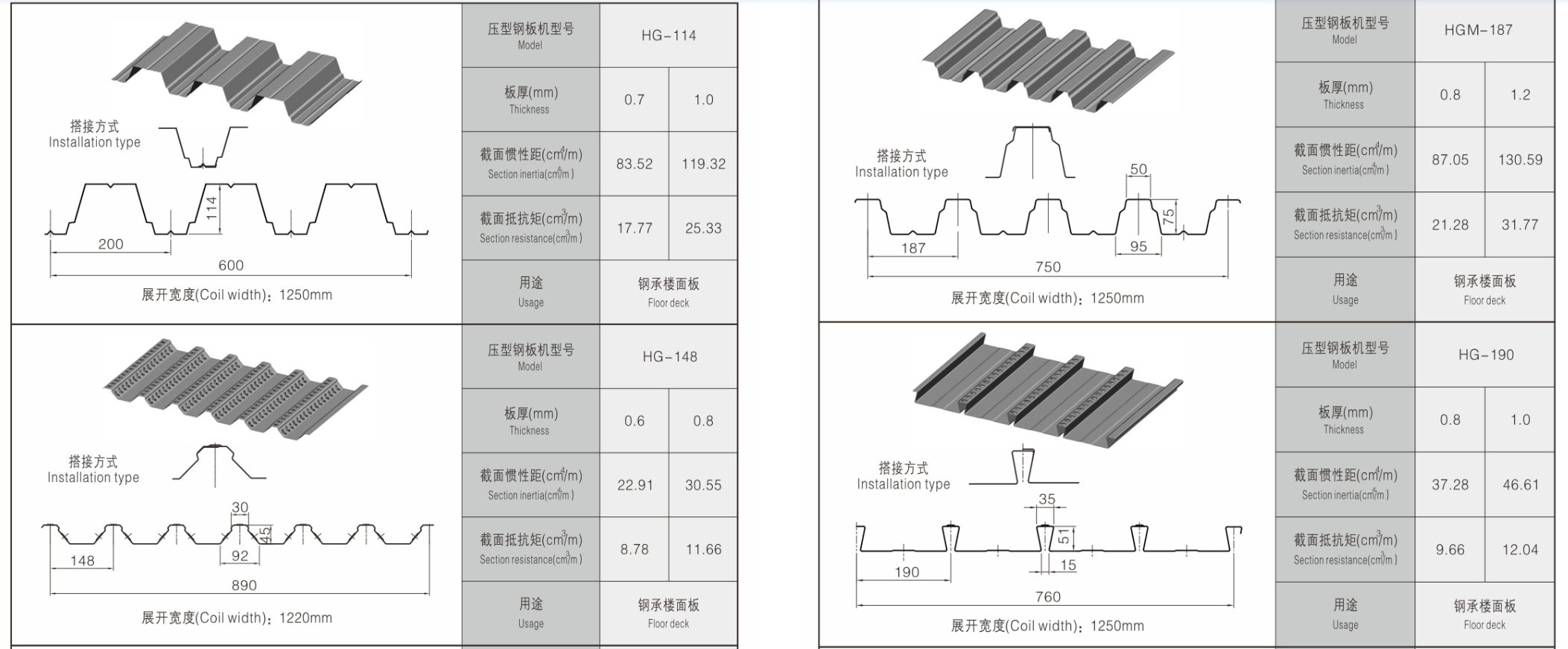

The common thickness for final products depends on different material , normally it 's 0.6-1.2mm. For the recommend profiles , we can recommend the popular end products and we can also design deck roll former according to your drawings .

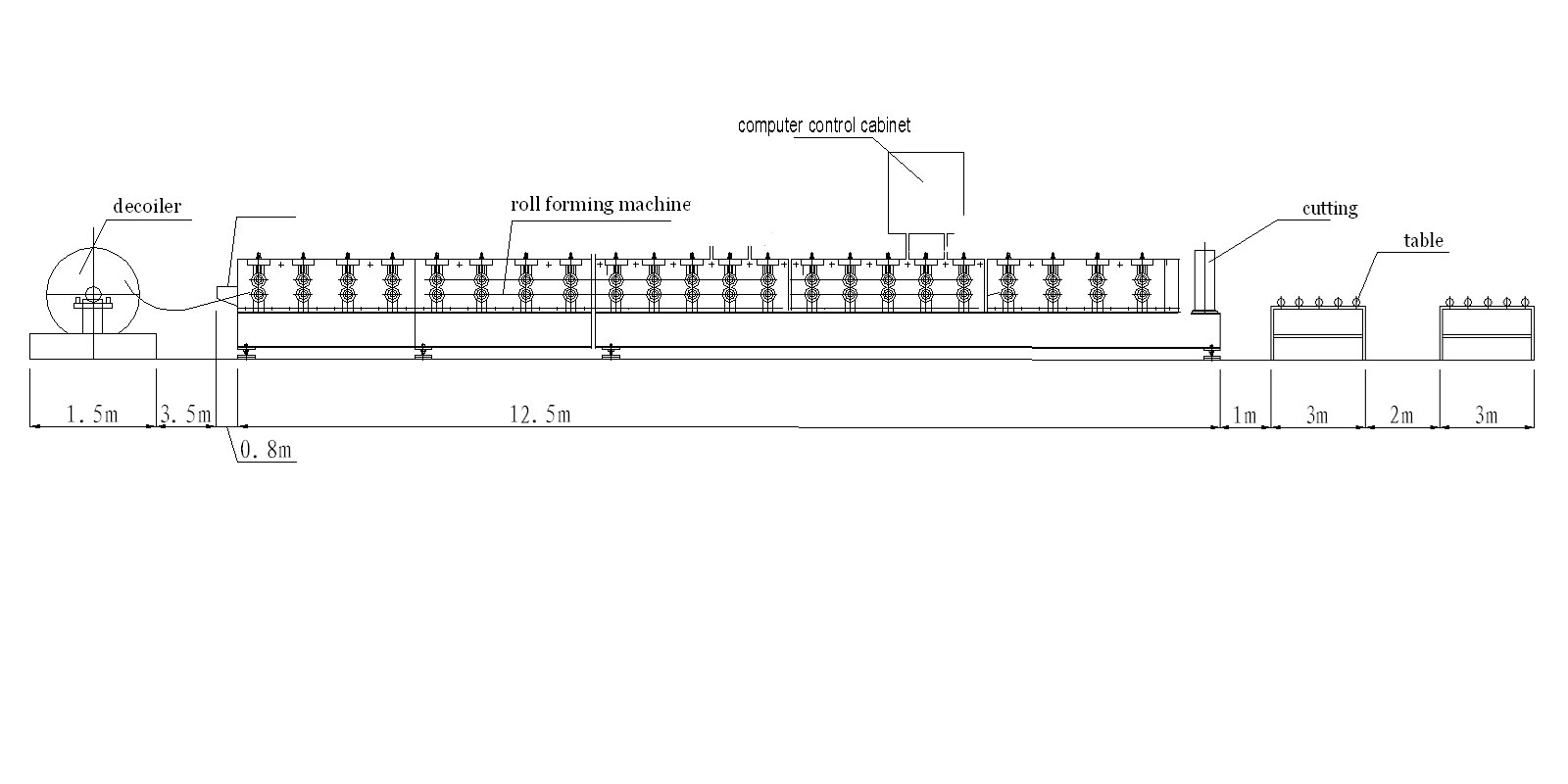

Working Flow:

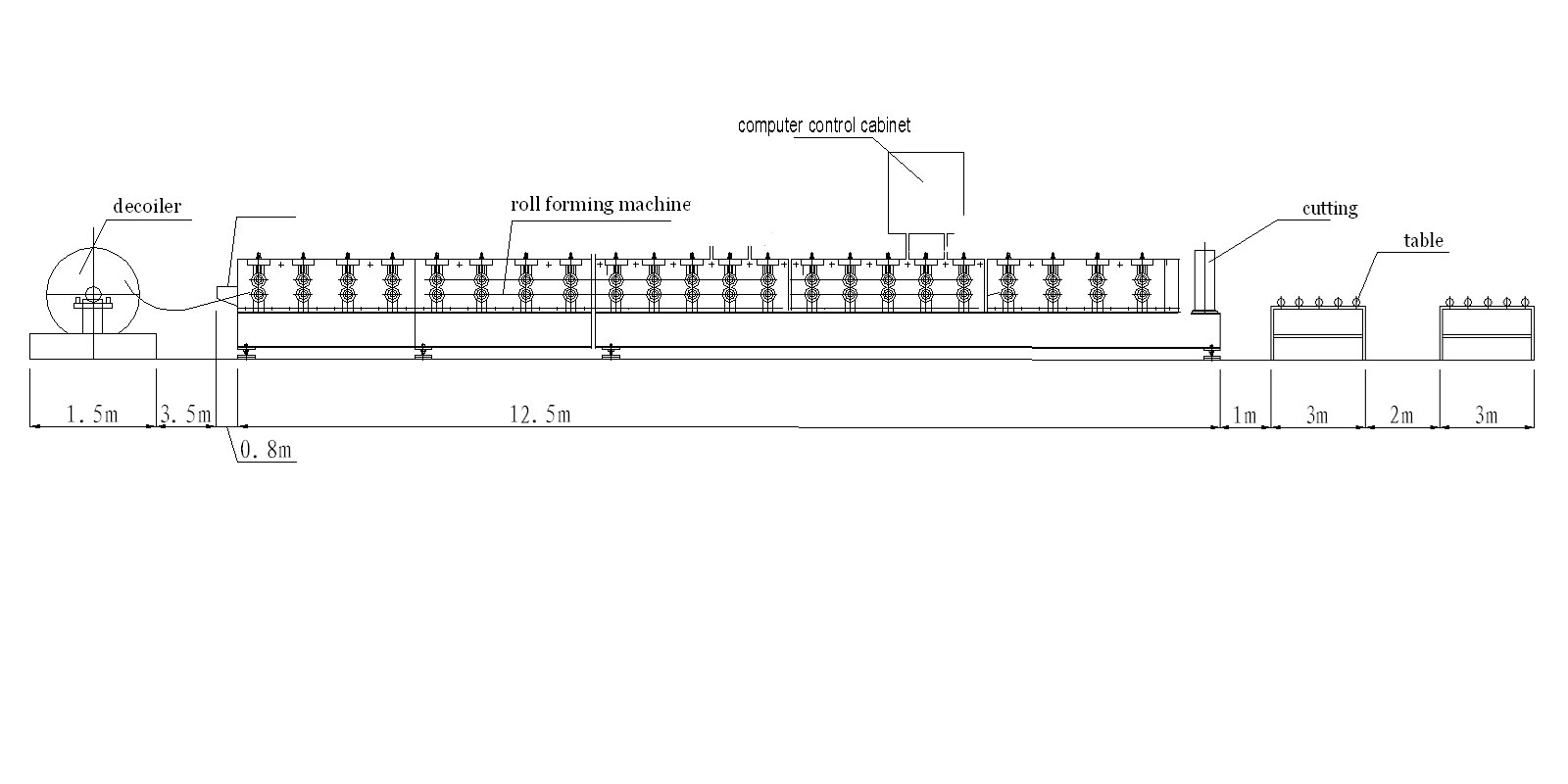

Decoiler---Entry Beach---Roll Forming Machine----- Automatic Shearing Mechanism---Computer Control Cabinet---Run-out Tables

Specification:

No. | Item | Unit |

|

| Floor Deck Roll Forming Machine |

1. | Material Of Processing |

| Galvanized steel |

2. | Thickness of steel plate | mm | 20 |

3. | Feed coil Thickness | mm | 0.7-1.0mm or 1.0-1.5mm |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 90 |

7. | Roll Station | No. | 24 |

8. | Rolling material |

| GCr15 |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed |

| 8-12 m/min |

11. | Drive Type of Roll Forming Machine |

| Chain |

12. | Power of Main Motor | kw | 15+15 |

Cutting Machine |

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 0.7-1.0mm or 1.0-1.5mm |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Delta |

21. | Frequency conveter |

| Delta |

22. | Frequency converter power | kw | 5.5 |

23. | Dimension Of Machine |

| About 12m*1.4m*1.2m |

24. | Weight | kgs | 11000 |

Main components of Steel Floor Deck Roll Forming Machine:

The line consists of uncoiler , transmission , roll forming , post - shearing , auto stacker , hydraulic system , controlling system , and etc .

Uncoiler:

Cantilever - type fully automatic uncoiler adopts ultrasonic sensor technology and frequency inverter adjustment . The pressing arm hydraulic - driven power is optional . All electrical

parts and hydraulic parts are installed inside of uncoiler frame .

Roll Forming:

The roll forming system consists of a guiding device , machine base , transmission parts , and roll forming rollers , etc . The cooling and lubricating device is optional .

Post - shearing device:

The post - shearing device adopts frame - type hydraulic shearing . The panel is cut stably .

Auto staker:

Programming control can calculate the quantities of shear panels , and automatically stacking , moving transversally or lengthways for packing .

Hydraulic system

Hydraulic system is installed inside the machine base . The design is reasonable and compact .

Controller:

Delta PLC Frequency inverter adjustment to realize fully automatic operation .

Operator:

The operator can set parameters such as badges , length of panel ' s quantities in the touch screen

Details of roll forming machine:

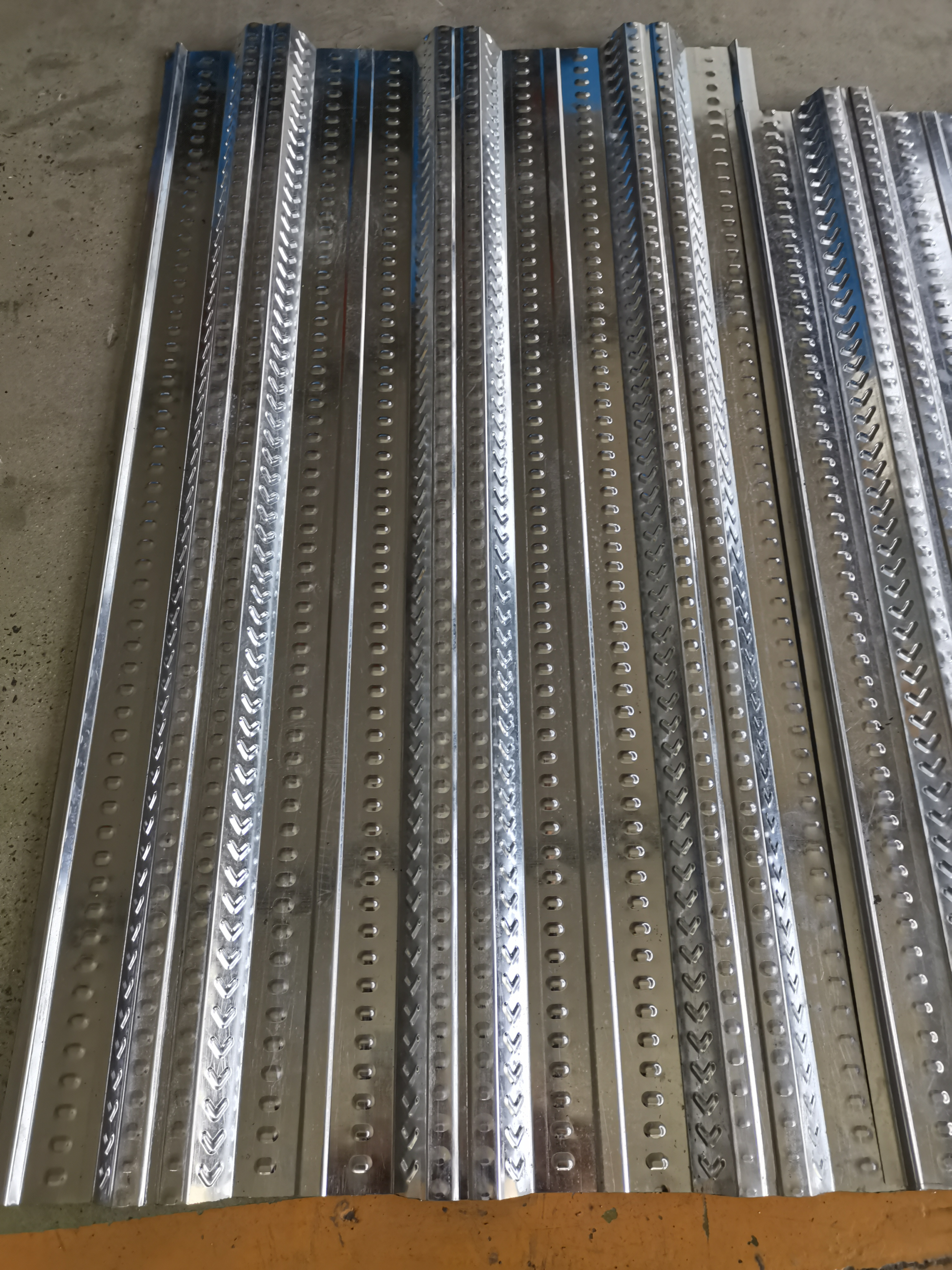

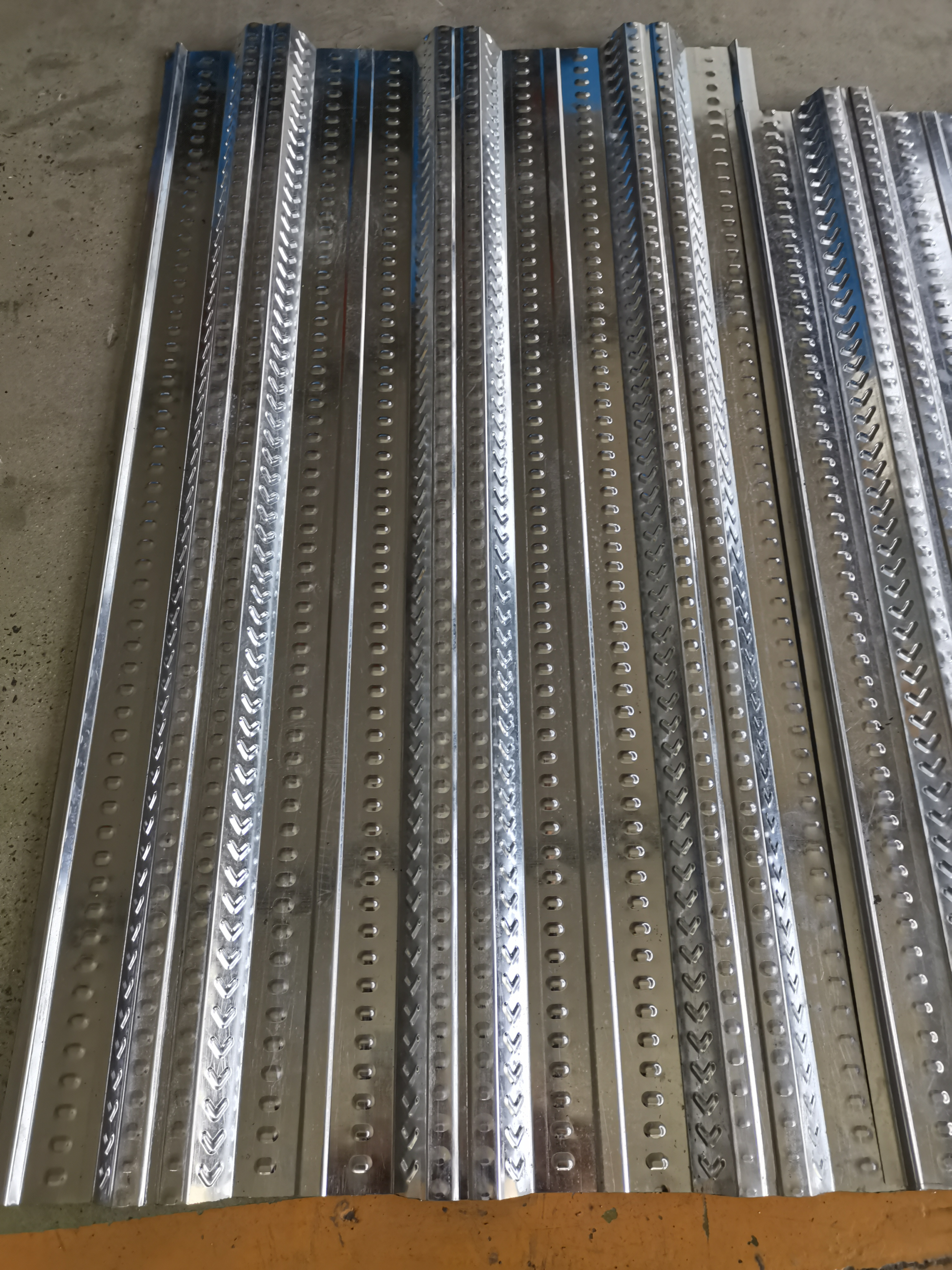

We can design the embossing flower with your market requst.

Please check the clear pattern on the steel deck:

2.5 inches chain to make sure deck roll forming machine is produce 0.8-1.2mm thickness material.

Other Machines of We have:

Package And Delivery: