Application Of Steel Floor Decking Roll Forming Machine

The steel floor decking roll forming machine is specifically designed for the production of steel floor decking panels, which have various applications in the construction industry. Here are some common applications:

1.Commercial and Industrial Buildings: Steel floor decking panels are commonly used in the construction of commercial and industrial buildings. They provide a strong and durable flooring solution that can support heavy loads, such as machinery, equipment, and storage. The panels are typically used in the construction of floors, mezzanines, and roofs.

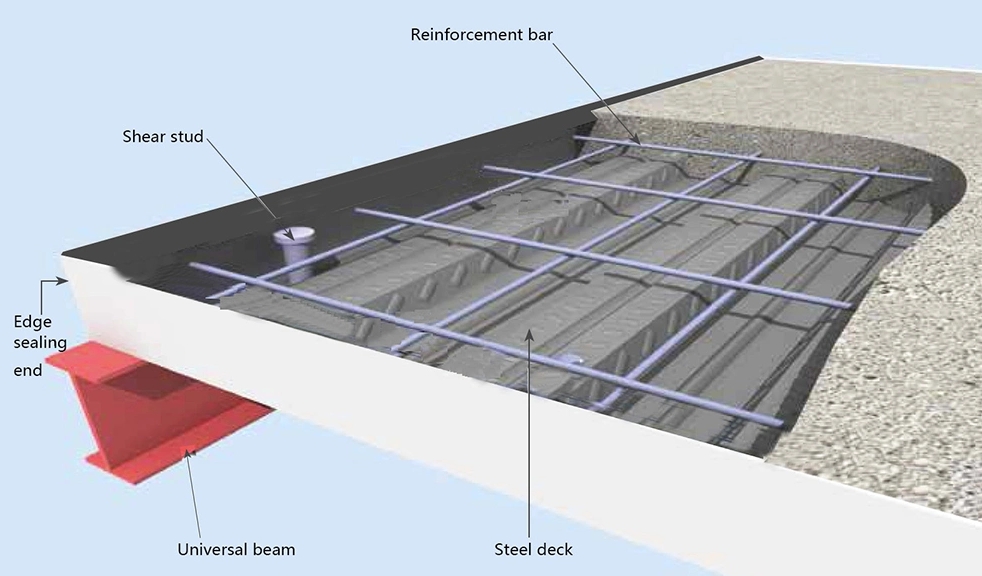

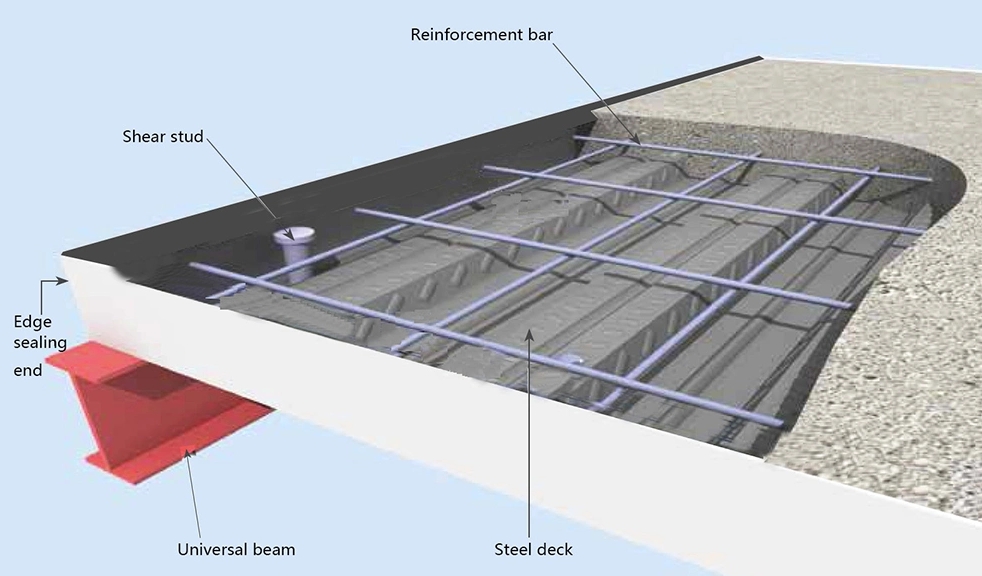

2.High-Rise Buildings: In high-rise buildings, steel floor decking panels are used as a formwork system during the construction process. The panels are installed temporarily to support the wet concrete during the pouring and curing stages. Once the concrete has hardened, the steel decking panels become an integral part of the floor structure, providing strength and stability.

3.Composite Floor Systems: Steel floor decking panels are often used in composite floor systems, where they work together with reinforced concrete. The panels act as a formwork during the concrete pouring stage and later serve as tensile reinforcement for the composite floor. This combination results in a strong, lightweight, and efficient floor system.

4.Residential Construction: Steel floor decking panels are also used in residential construction projects. They can be used as a flooring solution for houses, apartments, and condominiums, providing a sturdy and reliable surface for living spaces.

5.Bridge Construction: Steel floor decking panels find application in bridge construction as well. They are used as bridge deck components, providing a solid and durable surface for vehicles to travel on. The panels can be designed to meet specific load requirements and bridge design specifications.

Overall, the steel floor decking roll forming machine enables the efficient production of floor decking panels that are widely used in various construction projects, offering strength, durability, and versatility in different applications.

How To Choose Composite Floor Deck Roll Forming Machine?

When choosing a composite floor deck roll forming machine, several factors need to be considered to ensure that you select the right machine for your specific requirements. Here are some key considerations:

1.Material and Specifications: Determine the type and thickness of the materials you will be using for the composite floor deck panels. Different machines may be designed to handle specific material types and thicknesses. Ensure that the machine you choose can handle the materials you plan to work with.

2.Production Capacity: Evaluate your production needs in terms of the desired output and speed. Consider the required production capacity in terms of the number of panels per hour or per day. Look for a machine that can meet your production targets efficiently.

3.Profile and Dimensions: Specify the required profile and dimensions of the composite floor deck panels. The machine should be capable of producing the desired profile accurately and consistently. Pay attention to the width, height, and any special features or embossments required.

4.Automation and Control System: Consider the level of automation and control system capabilities you need. Some machines offer advanced features such as touch screen interfaces, programmable logic controllers (PLCs), and automatic adjustment systems. These features can enhance productivity, precision, and ease of operation.

5.Roll Forming Design: Assess the design of the roll forming stations, tooling, and cutting mechanisms. Look for a machine that has sturdy construction and high-quality components to ensure reliable and consistent performance over time. The tooling should be durable and easily adjustable for different panel profiles.

6.After-Sales Support: Evaluate the reputation and after-sales support provided by the manufacturer or supplier. Ensure that they offer comprehensive technical support, training, and access to spare parts. It’s beneficial to choose a reputable manufacturer with a proven track record in producing roll forming machines.

7.Cost and Return on Investment: Consider the cost of the machine and its potential return on investment. Compare prices, features, and capabilities of different machines to find the best balance between cost and performance. Additionally, consider the long-term savings and benefits that the machine can bring to your production process.

By considering these factors, you can make an informed decision when choosing a composite floor deck roll forming machine that meets your production requirements and offers efficiency, quality, and reliability.

Our Services:

1. We can produce the special machine,send your drawing to us,we can design for you.

2. If you buy our products,we also can help you to purchase the material,like color roll,the price is lower than you buy by yourself.

3. We provide a one year warranty and lifelong technical support, we can send our technicians to you to give you on-site training.

The training period would be for no more than one week with the customer paying for the visa, return ticket, food, accommodations and a daily wage of USD120.

4. Engineers available to service machinery overseas.

5. If you come to visit our factory,we can book the room for you, car pick up to send.