Display shelf columns Storage Rack Pallet Panel Slotted Angle Upright Frame Roll Forming Machine

Heavy shelves of goods in general to be put on the shelf through the tray, so when designing pillar, we have to take total weight of the goods into consideration.so this machine is produce rack thickness within 2.5mm.

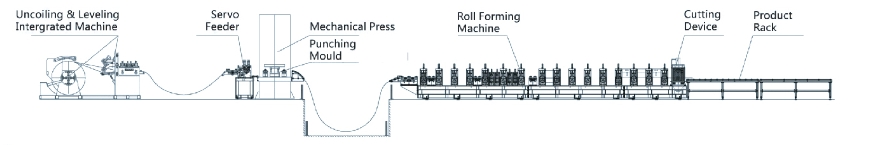

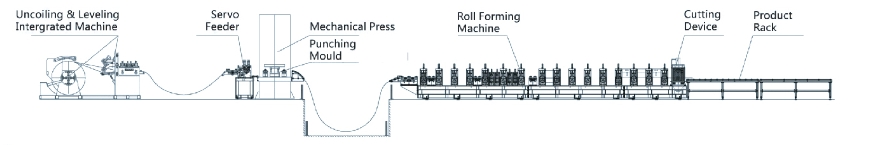

Working Flow:

Decoiler with leveling system---Servo feeder---Punching system---Roll forming machine---Cutting device---Product rack

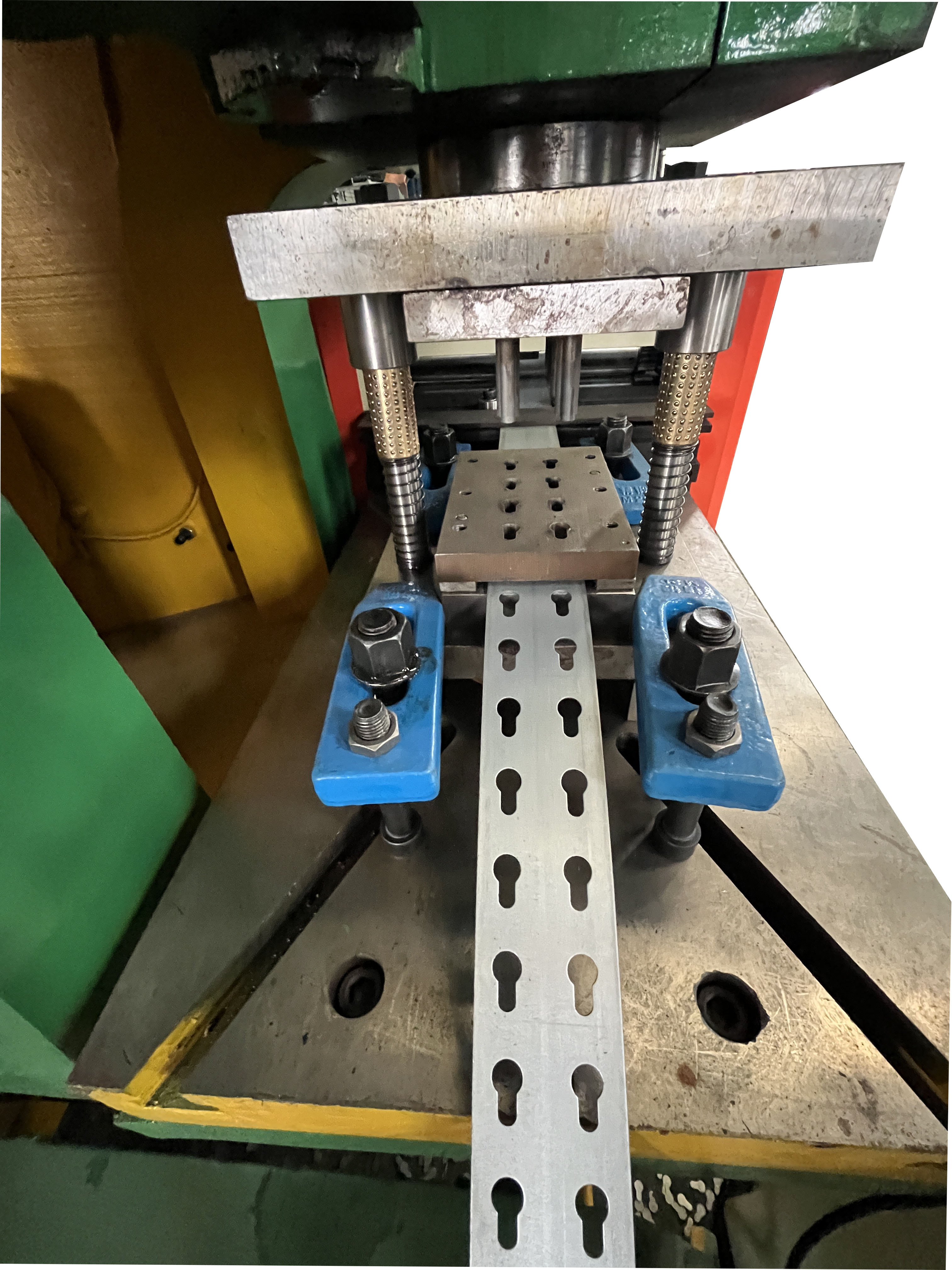

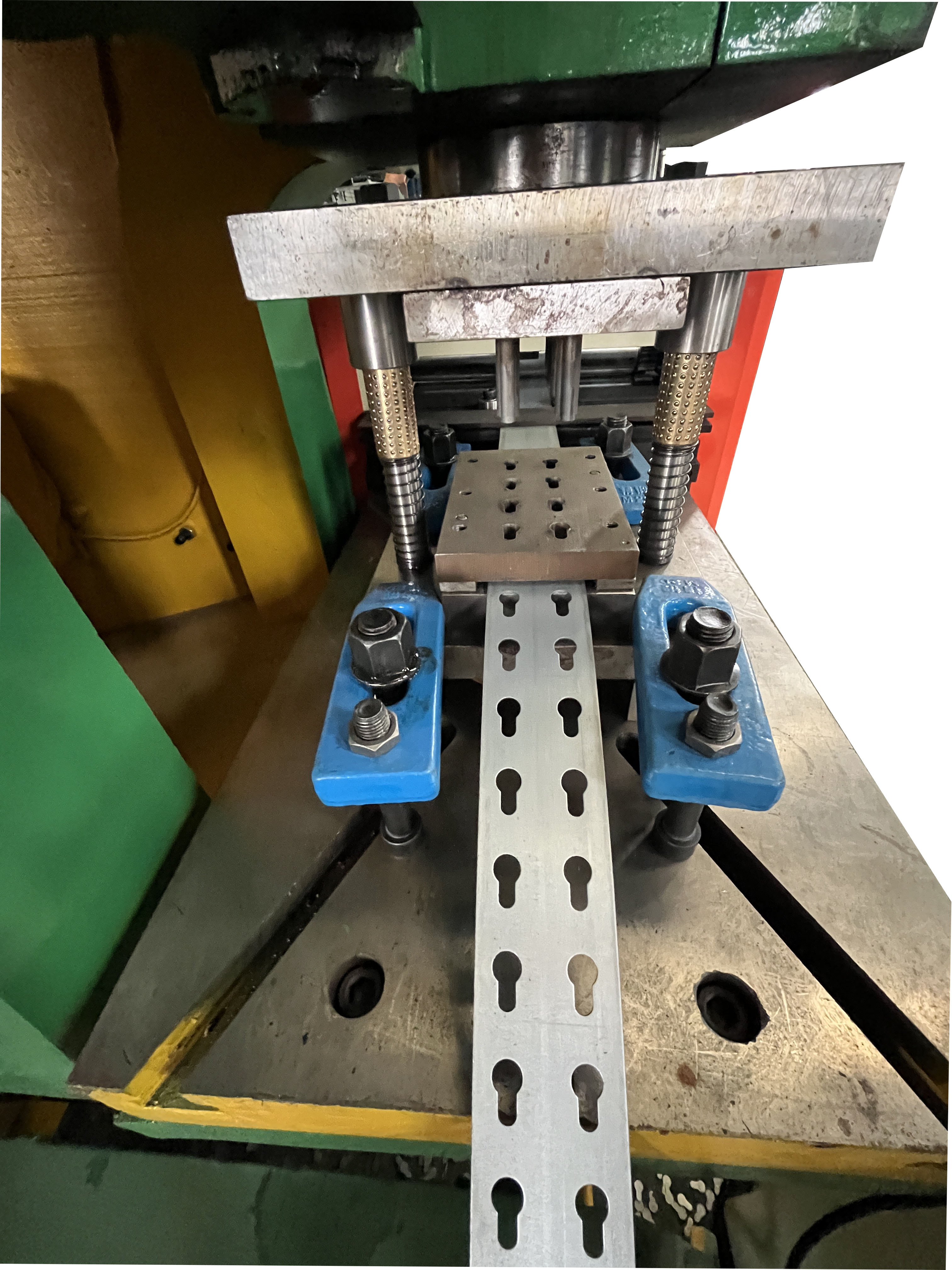

We customize die for your specical design of holes:

PLC is control full line working together, decoiler,punching machine and roll forming machine can match speed when they are running or stop. We only need set order on PLC,then full line will be working in automaticly, it is very easy to operating.

Specification:

No. | Item | Unit |

|

Design 1 |

1. | Material Of Processing |

| Galvanized Steel |

2. | Profile Type | mm | 65*30 |

3. | Feed coil Thickness | mm | 2.0-2.5 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 70 |

7. | Roll Station | No. | 16 |

8. | Rolling material |

| GCr15 |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Power | KW | 15 |

Cutting Machine |

11. | Type |

| PLC controlled By Flying Saw Cutting |

12. | Thickness capacity | mm | 2.0-2.5 |

13. | Width capacity | mm | As drawing |

14. | Cutting blade steel grade |

| Cr12, quenching |

15. | Hardness |

| 58-62 HRC |

16. | Cutting tolerance | mm | +/- 1 |

Control Unit |

17. | Type |

| PLC controlled |

18. | PLC brand |

| Delta |

19. | Frequency conveter |

| Delta |

20. | Frequency converter power | kw | 15 |

21. | Dimension Of Machine | m | 10m*1.5m*1.4m |

22. | Weight | kgs | 5500 |

23. | Working speed | m/min | 0-10 |

Use:

Slotted angle racks are the most-widely used shelving solution in every industry. These are heavy-duty, yet light-weight and an economical option for warehousing and other shelving needs. They are portable and can be transported easily using a forklift.

Package And Ship: