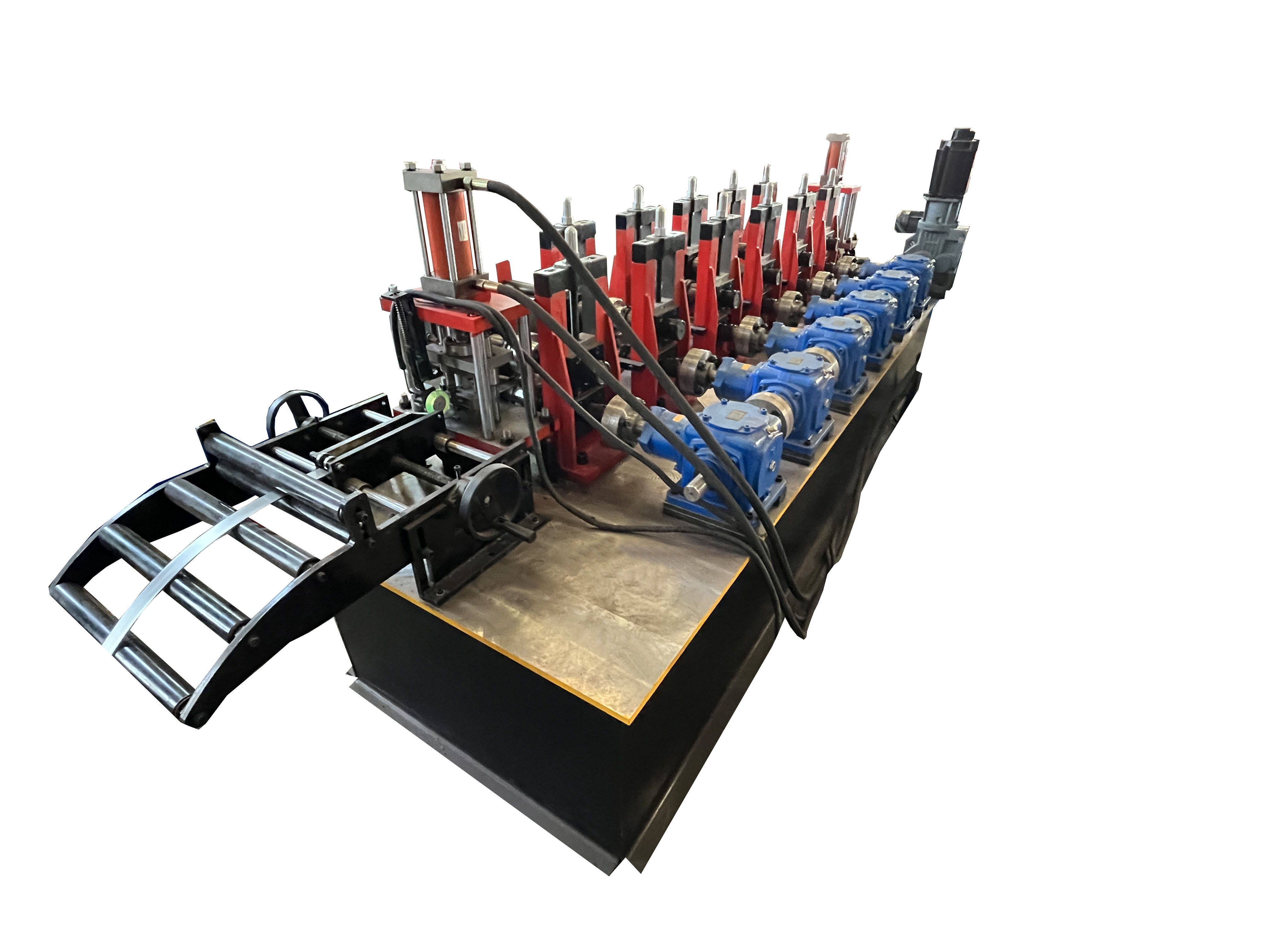

Customize Metal Sheet Frame Structure Special Steel Profile Cold Roll Forming Machine

Cold roll forming machine is can produce many kind of steel profile to meet with customer's requirement,please send your drawing to us if you have any interesting.

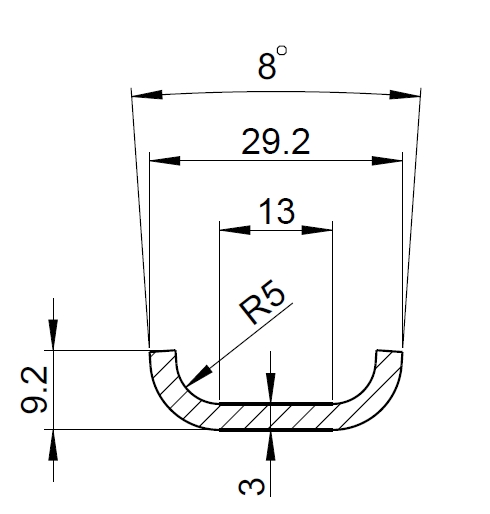

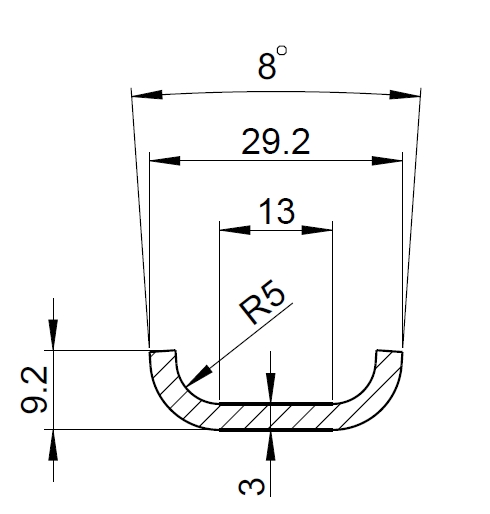

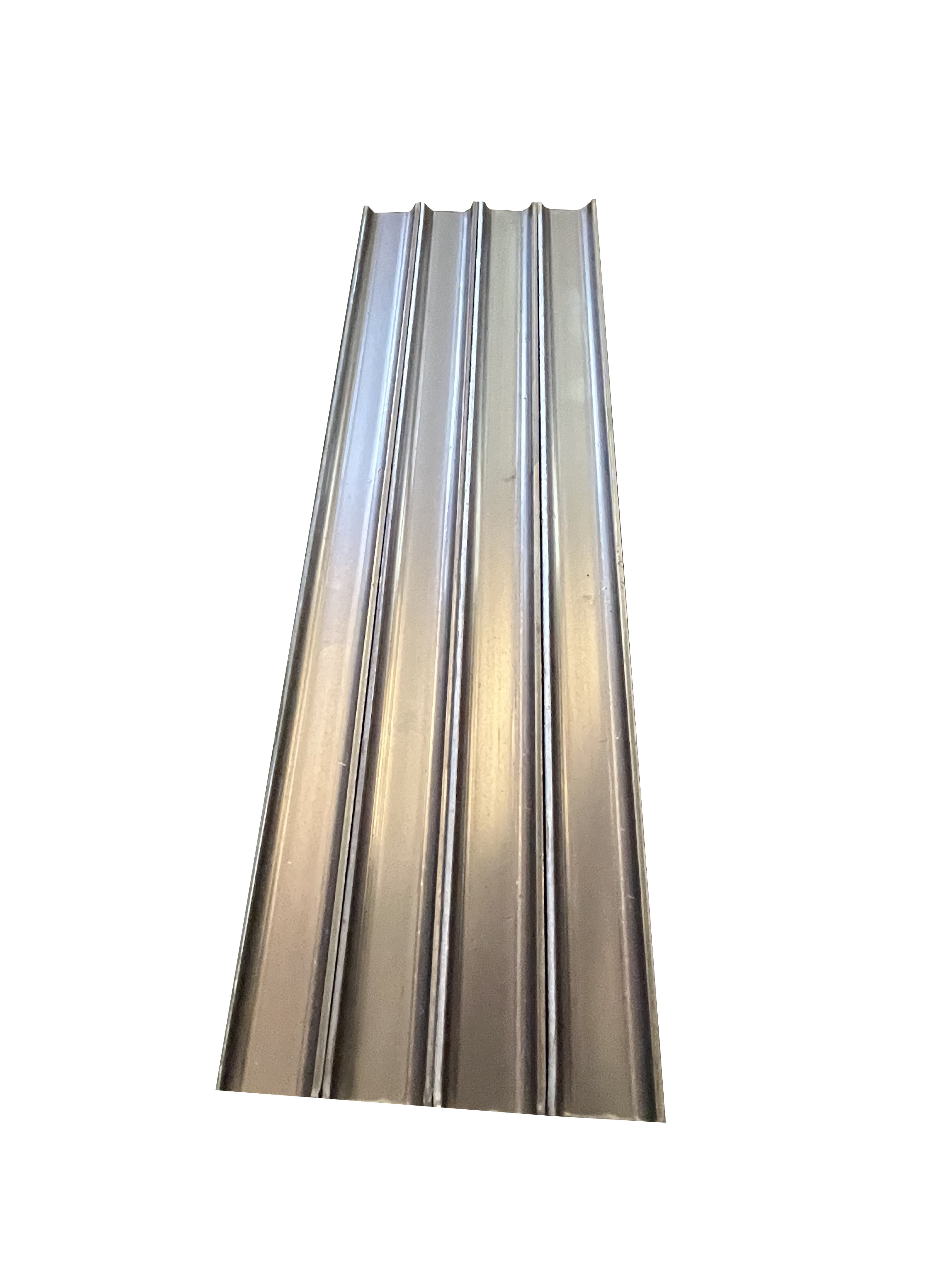

This design is motorcycle steel frame.

This profile cutting length in 600mm-900mm,so we use servo motor to improve the precision.

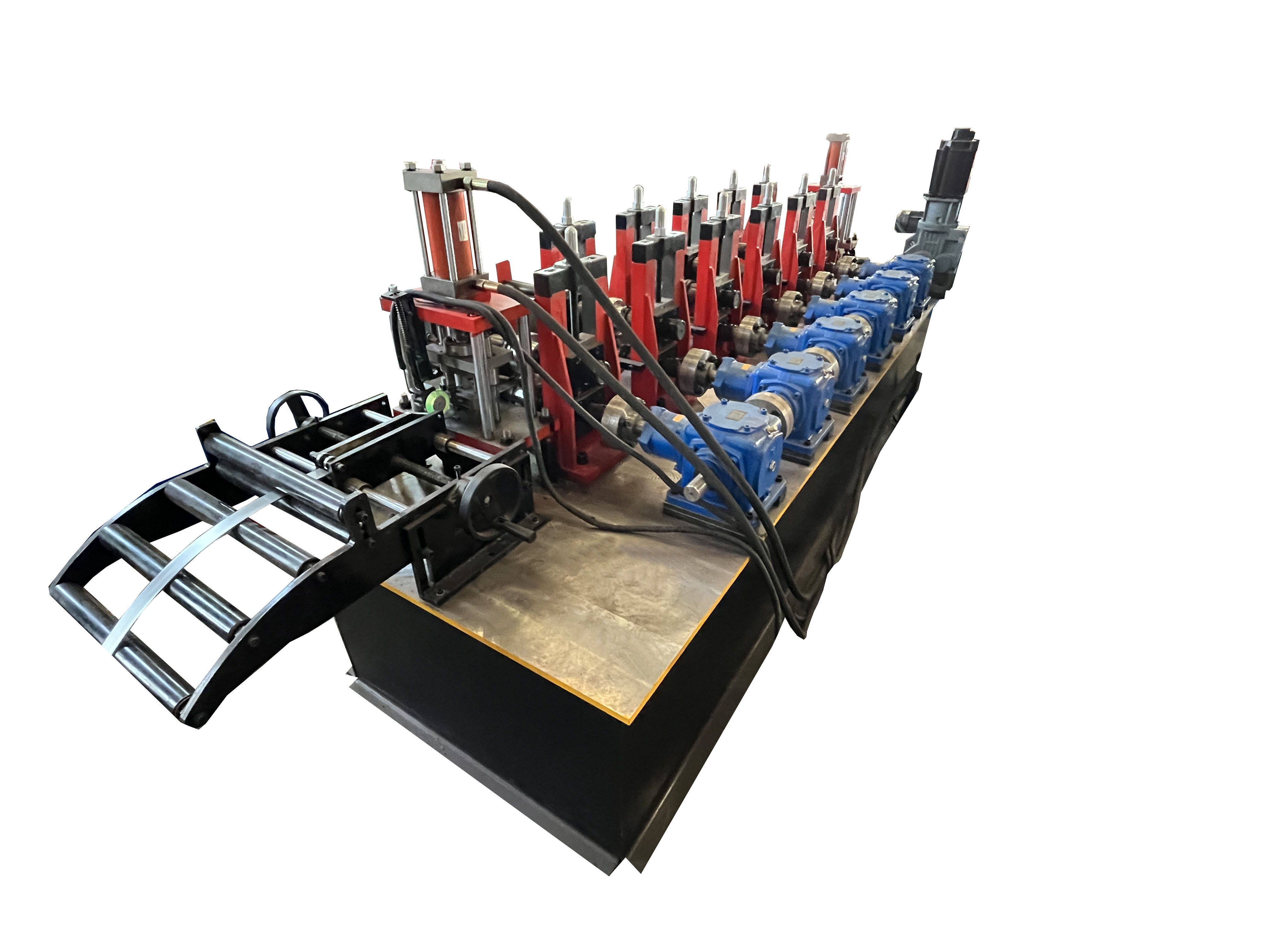

We use casting frame for all stations, it is can make sure machine working in stable.

Material thickness is 3mm, so machine driven by gearbox to make it is working powerful.

Cutting is controlled by hydraulic oil pump system:

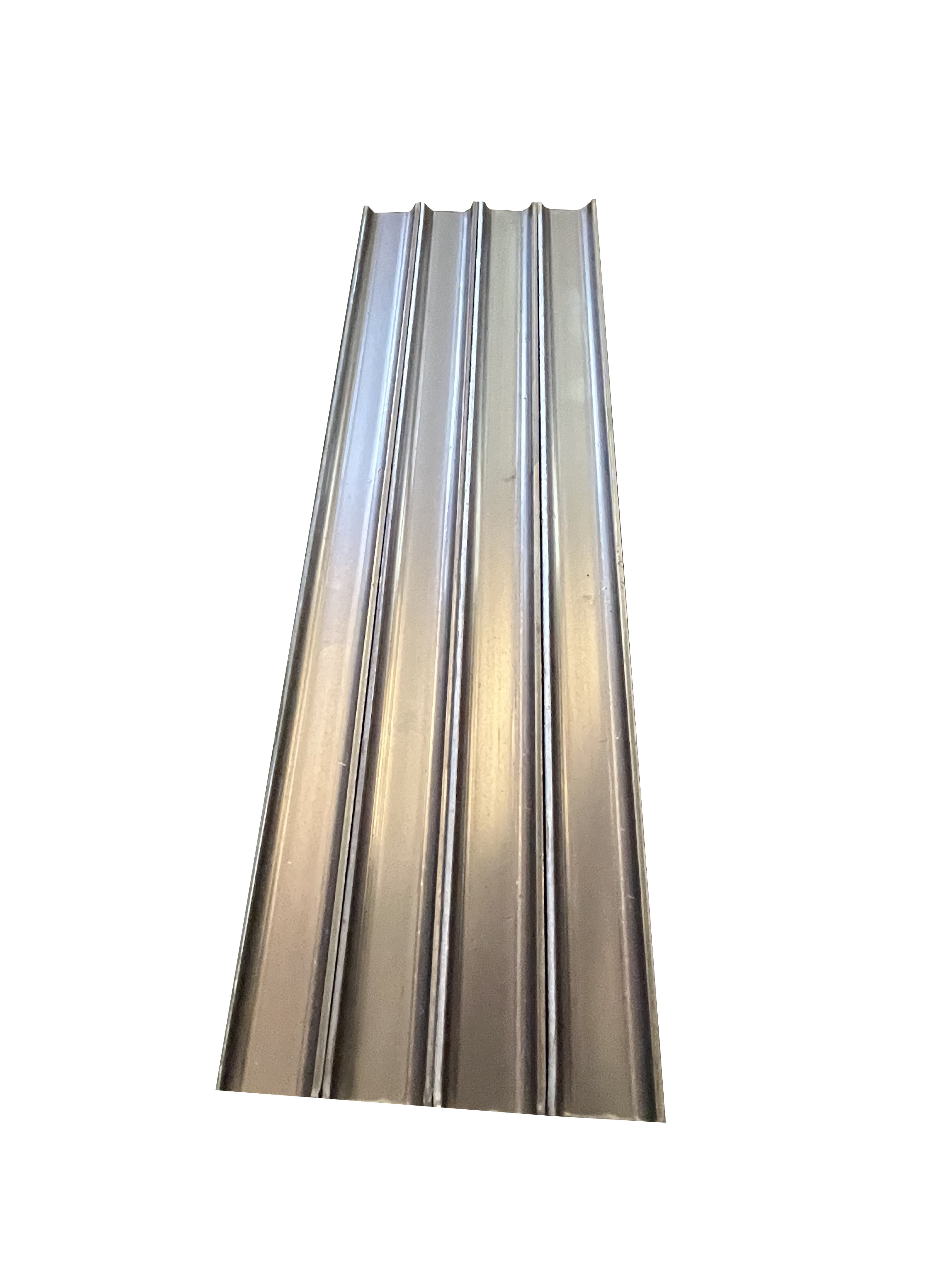

We test coil and compared with drawing to make sure everything is meet customer's requirement.

Specification:

No. | Item | Unit |

|

| C Profile Roll Forming Machine |

1. | Material Of Processing |

| Galvanized Steel |

2. | Profile Type |

| As customer’s request |

3. | Feed coil Thickness | mm | 2.0-3.0 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 70 |

7. | Roll Station | No. | 6 |

8. | Rolling material |

| GCr15 |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed |

| About 12-15 m/min |

11. | Drive Type of Roll Forming Machine |

| Gearbox |

12. | Power of Main Motor | kw | 7.5 |

Cutting Machine |

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 2.0-3.0 |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Delta |

21. | Frequency conveter |

| Delta |

22. | Frequency converter power | kw | 4 |

23. | Dimension Of Machine |

| About 3.5m*0.75m*1.4m |

24. | Weight | kgs | 2800 |

FAQ:

Q1. Do you have after-sales support?

A1: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q2. Do you sell only standard machines?

A2: No, most of our machines are built according to customers specifications, using top brand components.

Q3. What will you do if the machine is broken?

A3: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't

repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond

the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the

equipment.