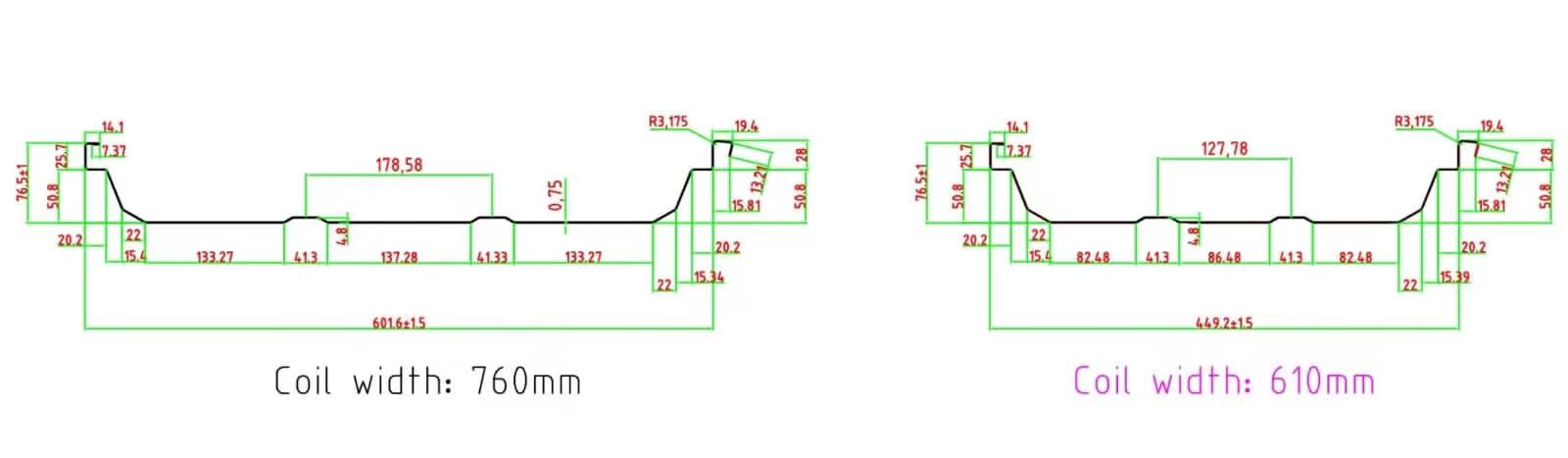

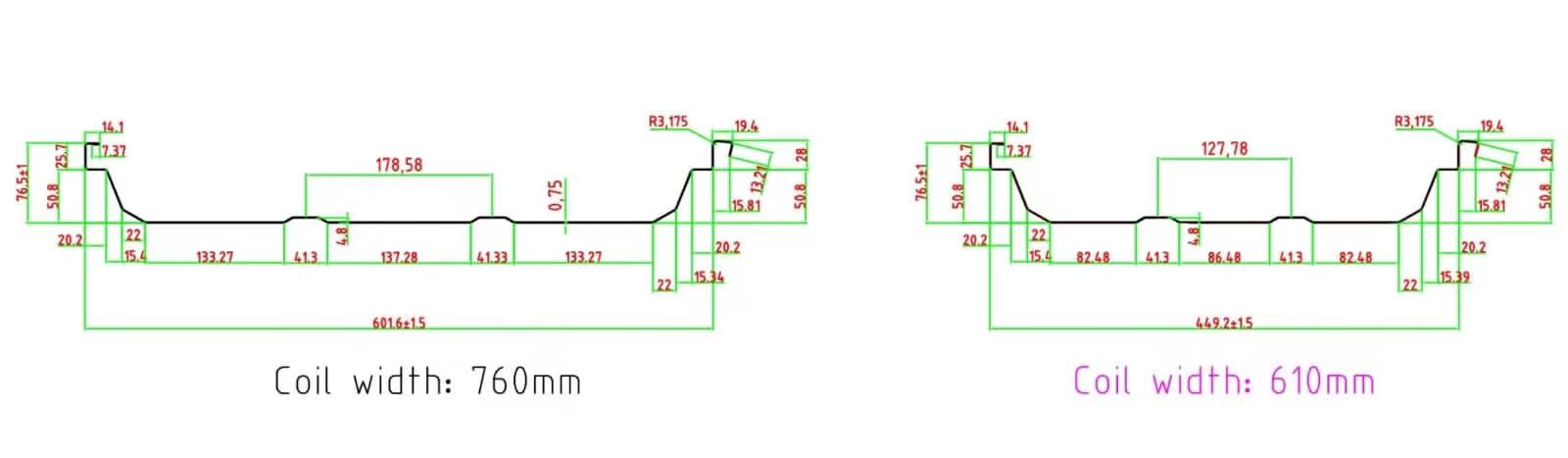

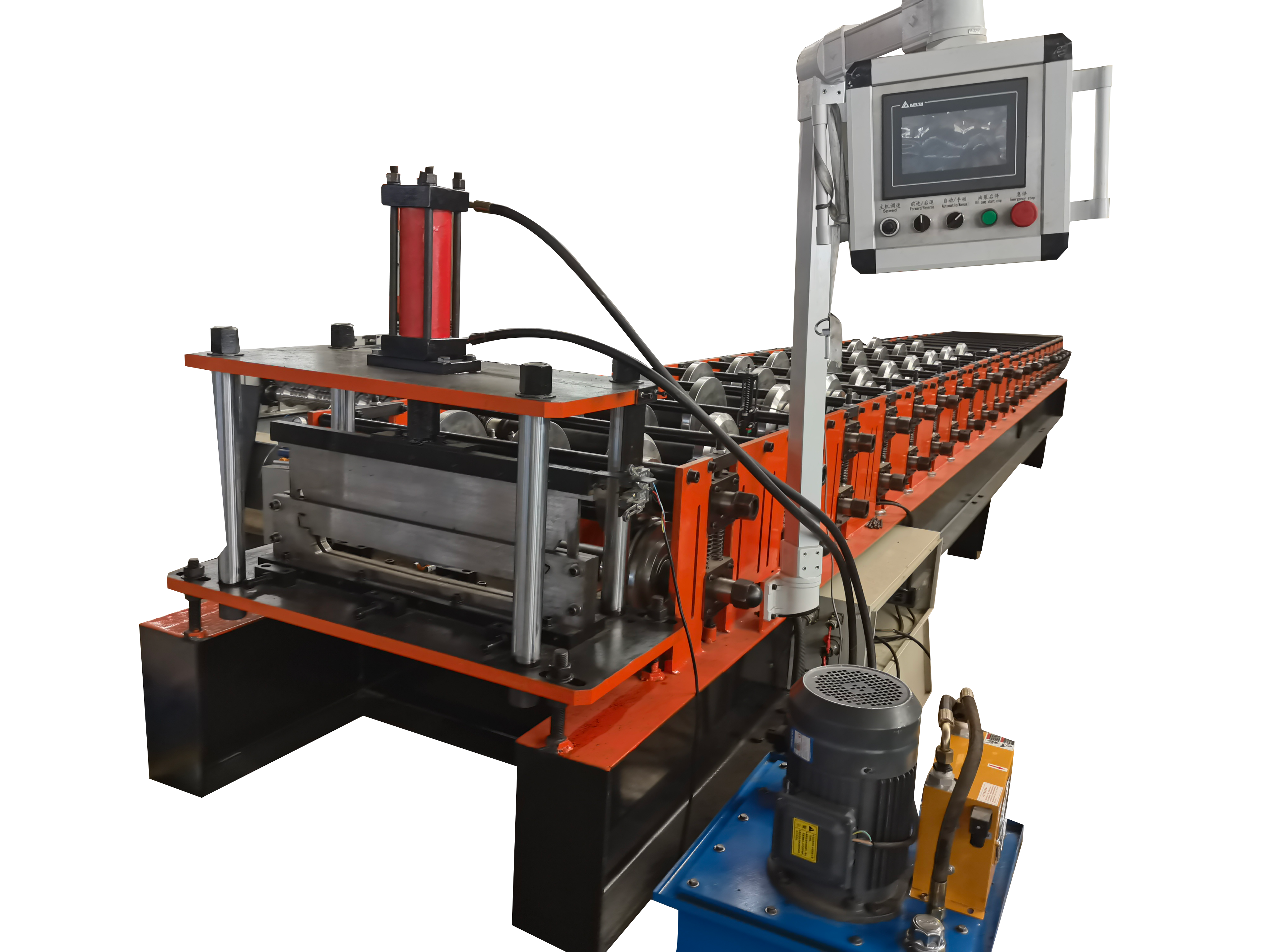

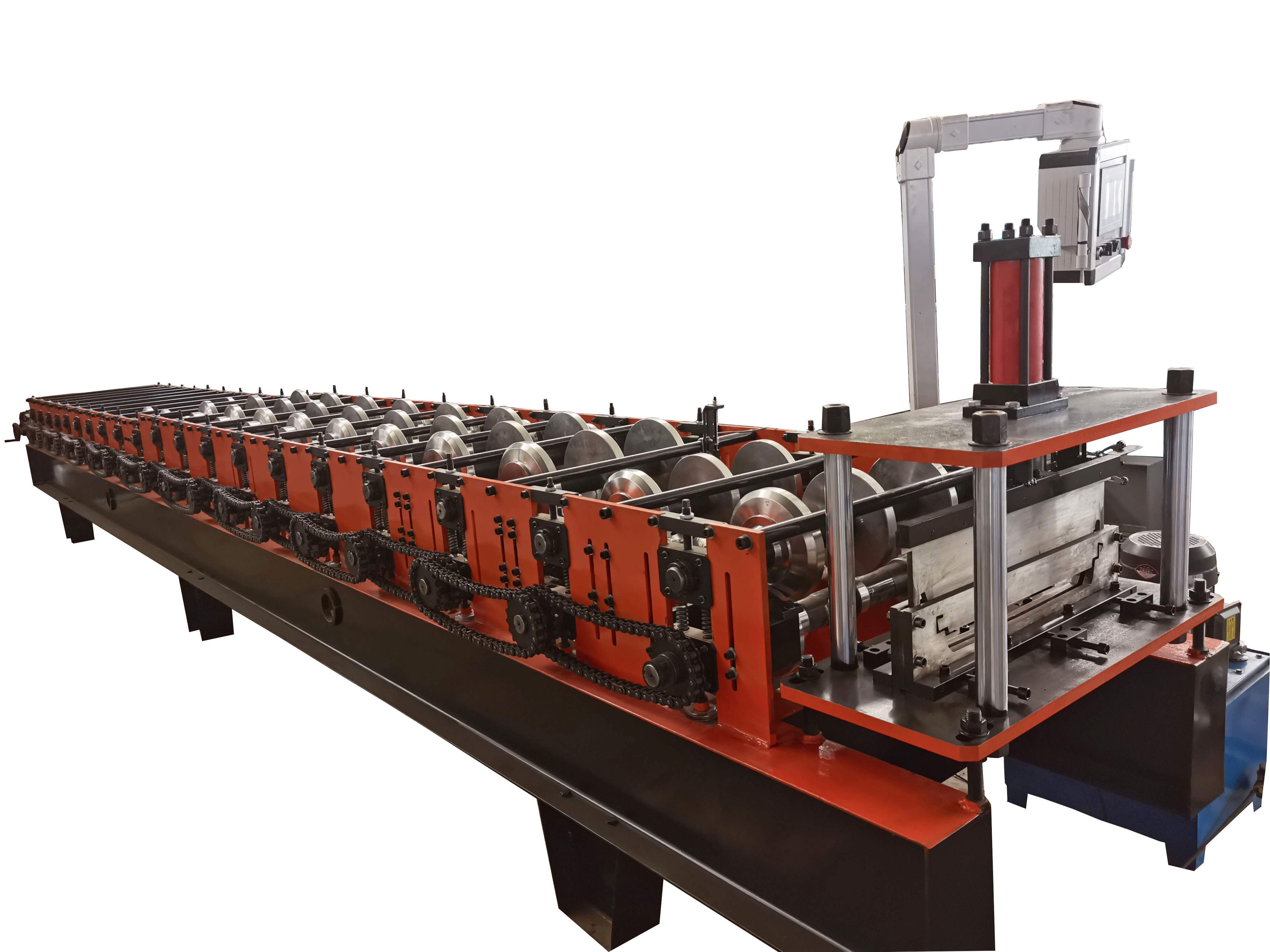

Standing Seam Roll Forming Machine

Standing seam metal roof machine has different types which used together with corrugated sheet and IBR sheet, or glazed tile sheet,selflock

roof machine. The sheet is widely used in many kinds of industrial factory, civilian buildings, and Roof board for attached part product It

has advantage of pretty appearance, durable using and so on.

Specification:

No. | Item | Unit |

|

1. | Material Of Processing |

| PPGI |

2. | Profile Type |

| As customer’s request |

3. | Feed coil Thickness | mm | 0.4-0.8 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

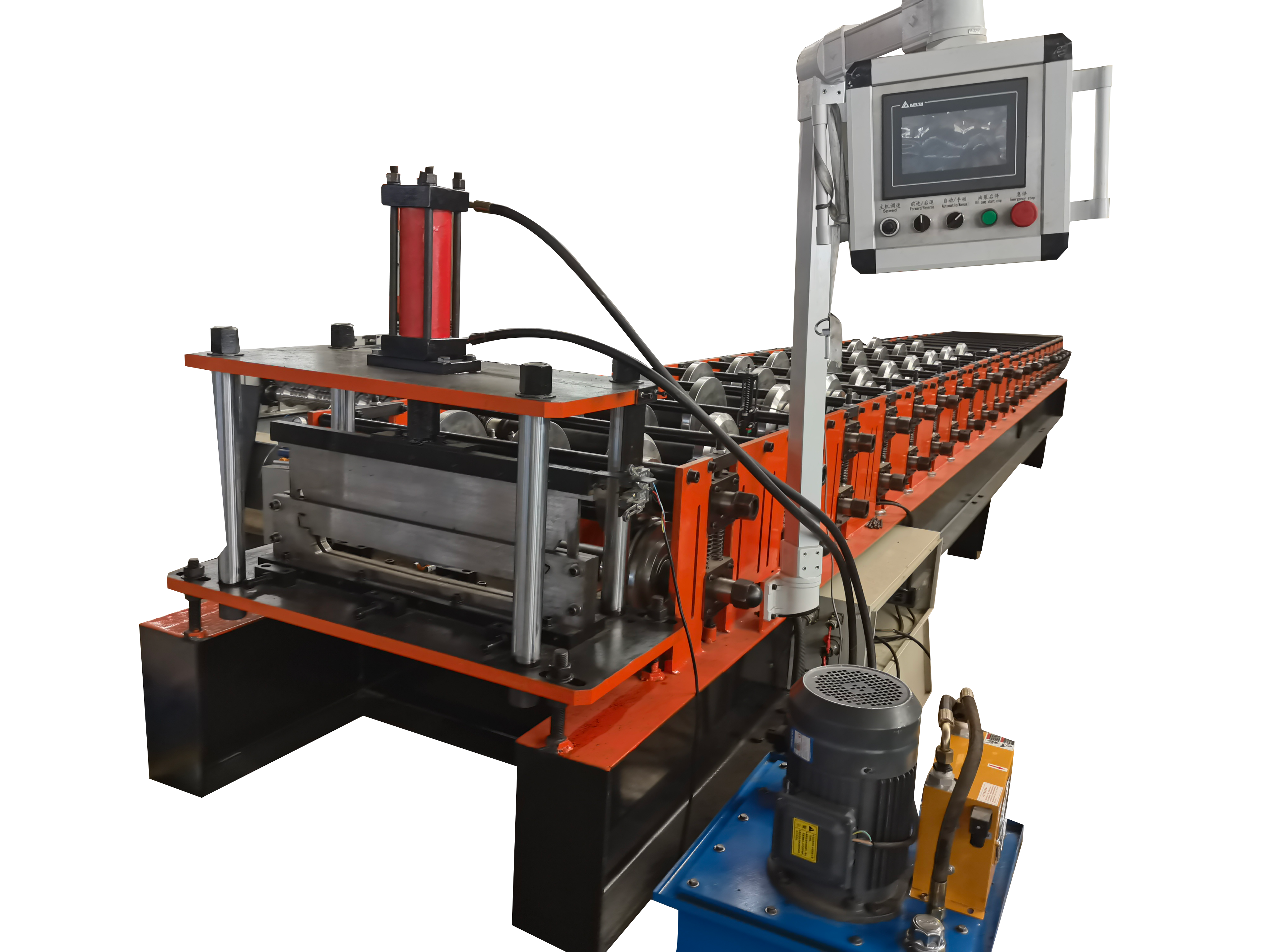

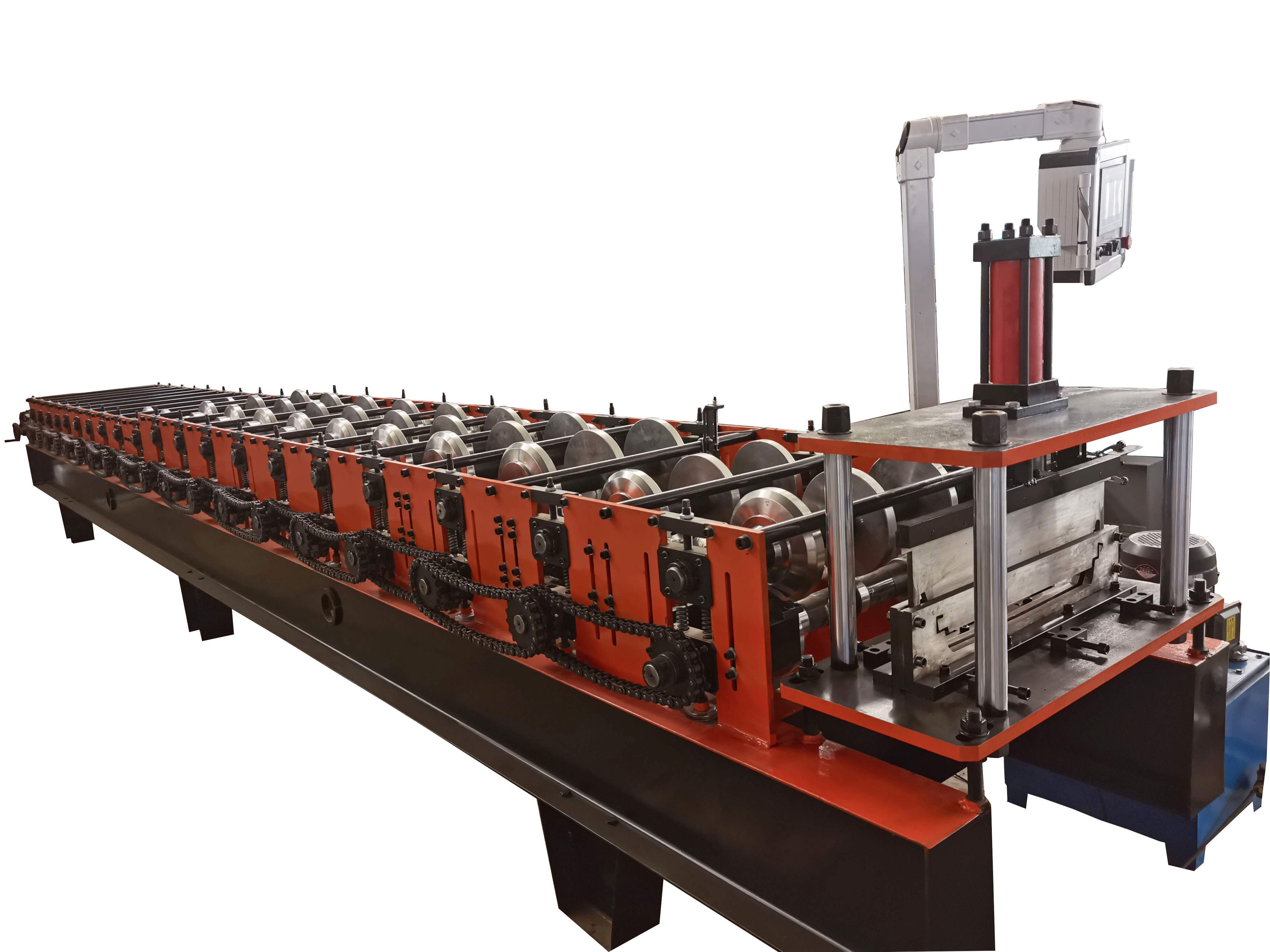

6. | Shaft Diameter | mm | 70 |

7. | Roll Station | No. | 20 |

8. | Rolling material |

| 45#Steel |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed |

| About 12-15 m/min |

11. | Drive Type of Roll Forming Machine |

| Chain |

12. | Power of Main Motor | kw | 7.5 |

Cutting Machine |

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 0.4-0.8 |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Delta |

21. | Frequency converter power | kw | 4 |

22. | Dimension Of Machine |

| About 9m*0.9m*1.2m |

23. | Weight | kgs | 4500 |

24. | Working area | m | 20*3 |

25. | Voltage |

| 3800V,50HZ,3Phase |

Hydraulic Bending Machine Match With Standing Seam:

It is can adjust angle by PLC, and it is can bending for long sheet, because machine can turn down.

Automatic Seaming Machine: