Sandwich Panel Roll Forming Machine

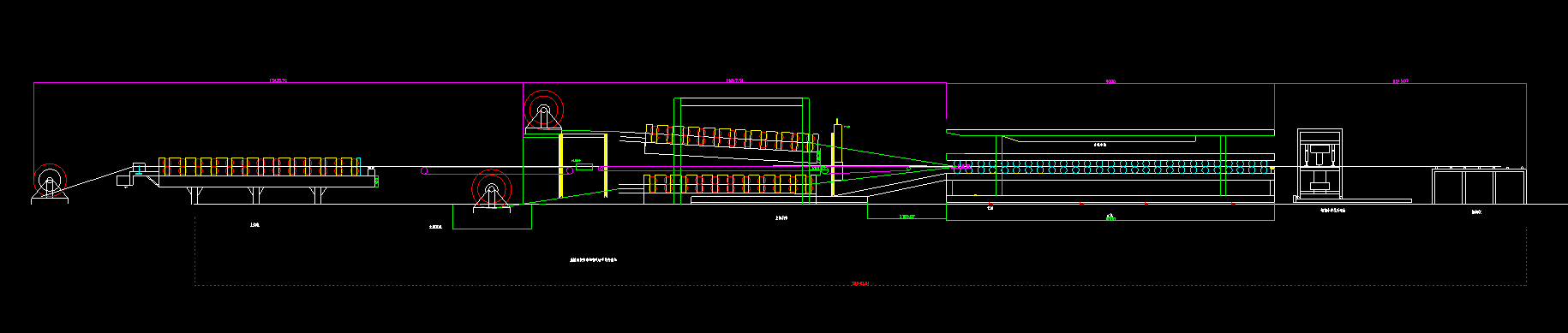

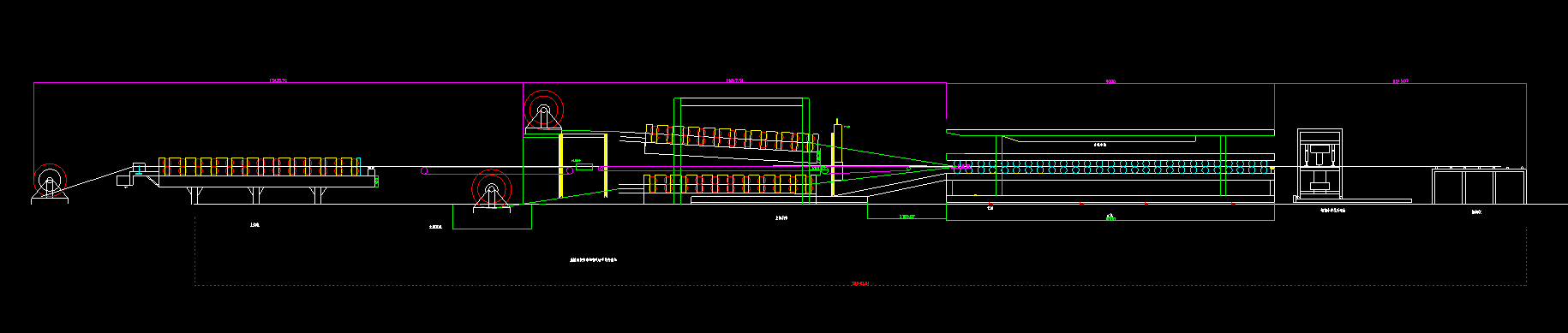

EPS/Rock Wool/Z Lock panel design can be choosed ,we can customized sandwich panel roll forming machine. It is complete working line from Decoiler---Roof sheet roll forming machine---Two decoilers---Z Lock roll forming machines---EPS or Rock Wool feeder system---Glue system---Sandwich panel roll forming---Cutting system---Table.

Product Size :

Product by this line | Steel + rock wool |

Middle material | Rock wool strips insulated panel |

Thickness 50~200mm |

Metal sheets | PPGI , GI, AL... (Note : if do stainless steel ,please tell , roller material is different ) |

Thickness 0.3~0.6mm |

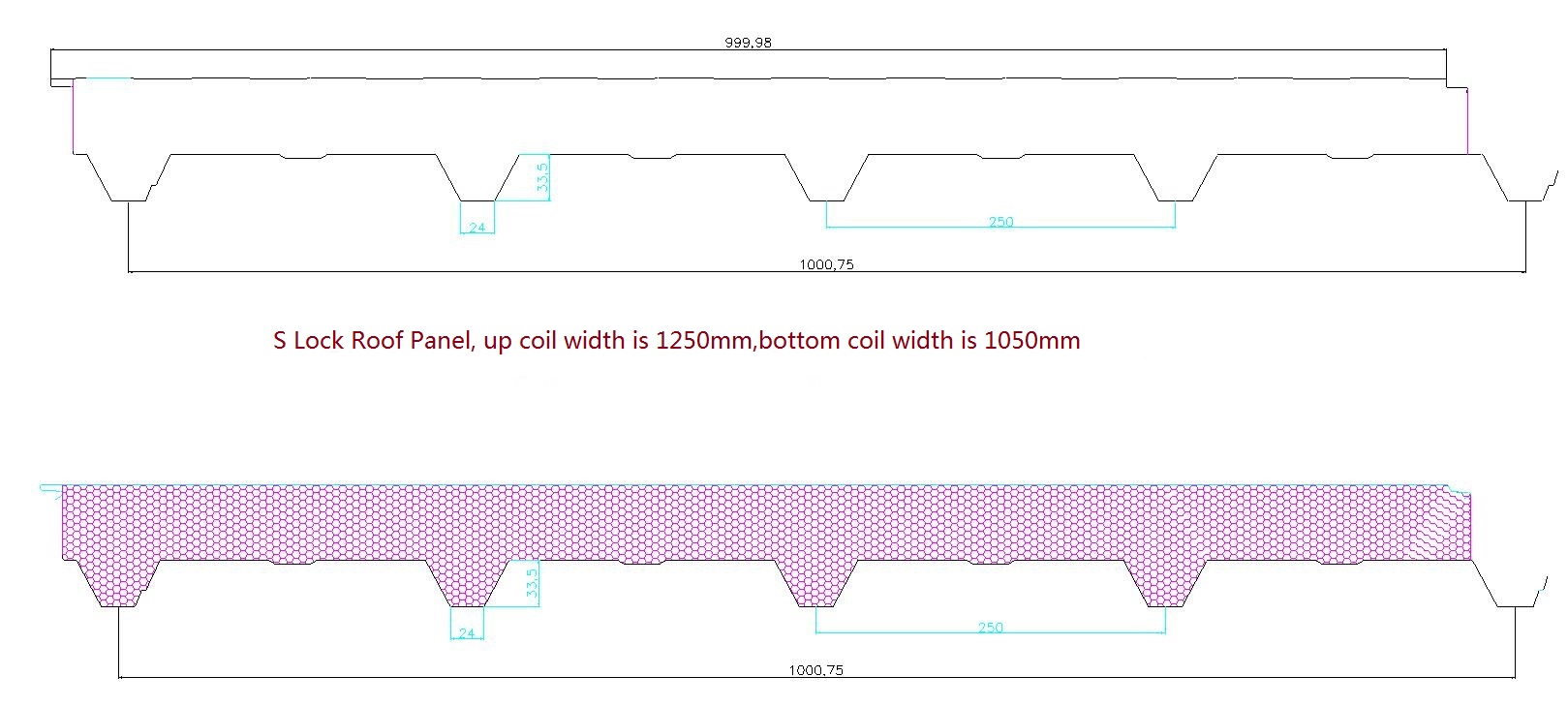

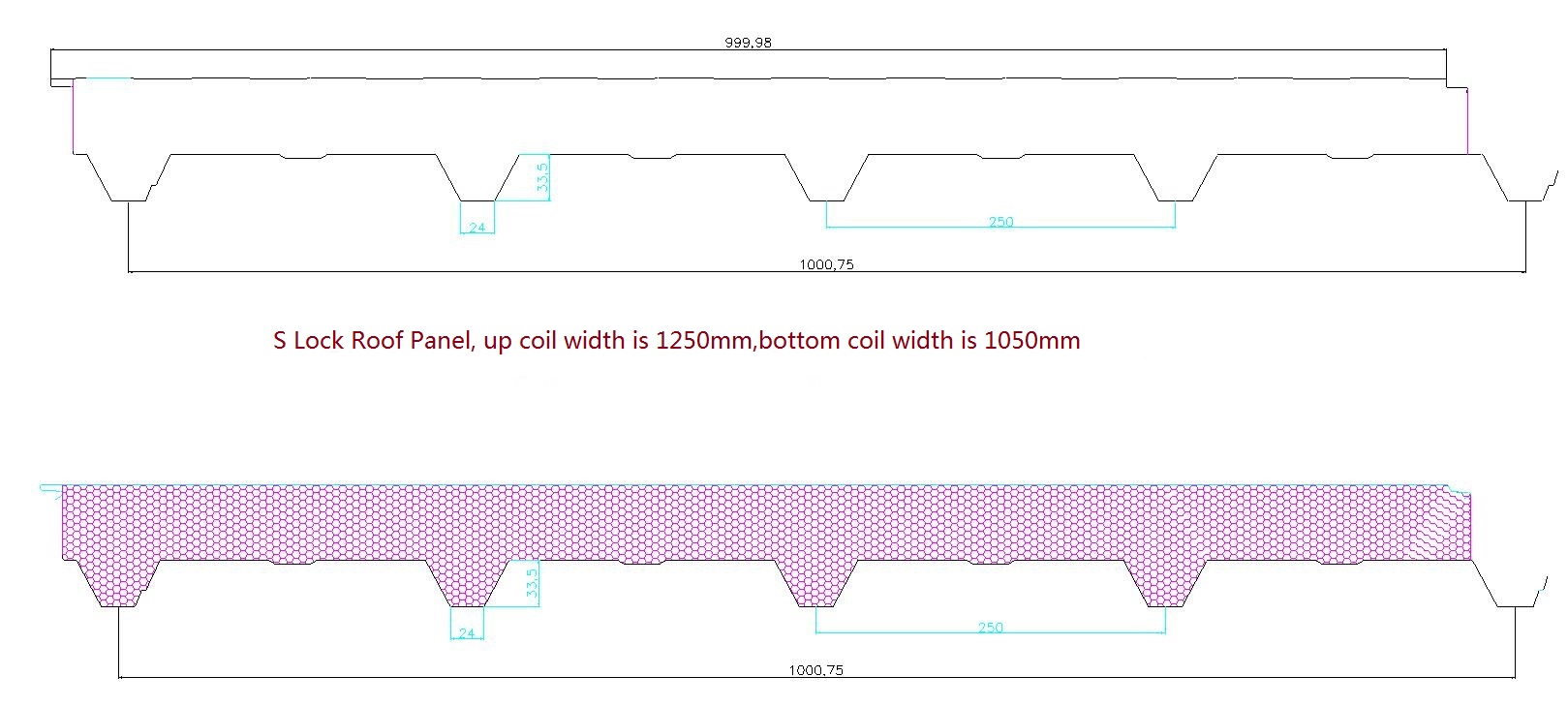

Design for roof:

Coil width of upper plate: 1250mm; Coil width of bottom plate: 1050mm.

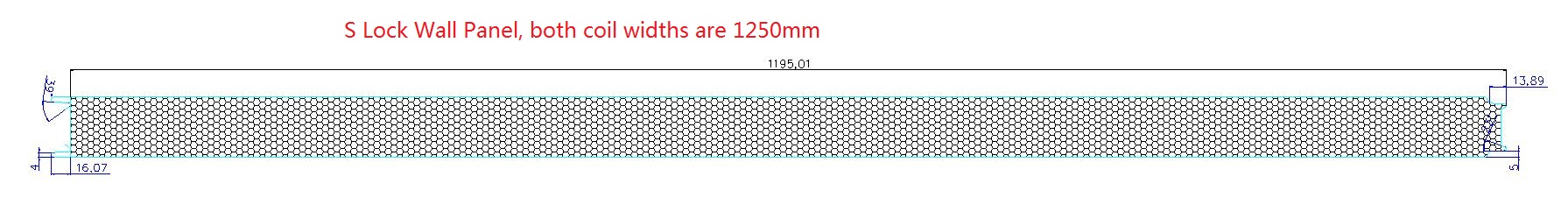

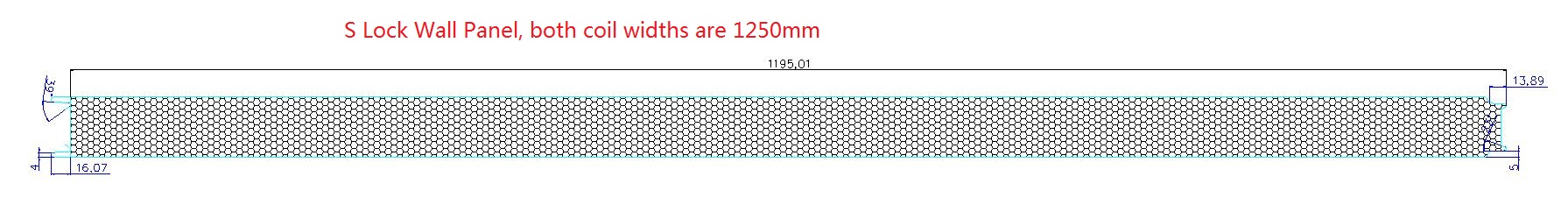

Design for wall:

Coil width of upper plate: 1250mm; Coil width of bottom plate: 1050mm.

EPS And Rock Wool Sandwich Panel Production Line |

NO. | Name | QTY (Set) | Remark |

Part 1 | Roof sheet and wall panel roll forming machine | 2 | Forming |

Part 2 | Feeding Device of rock wool strips (manual feeding) | 1 |

|

Part 3 Sandwich Panel Laminating System | Longer Main Press Machine | 1 | 9.0m, 50 stations up and down (25 couples) |

Bigger Pressing Rubber Rollers Whole Pieces Thicker Rubber Roller Layer | 1 | Roller diameter: 180 mm Thickness of composite rubber layer of whole piece roller:13mm Hardness of composite rubber layer:50~60 |

Leveler for thickness | 1 |

|

Glue system | 1 | 4 pumps , 2 motors , 2 inverters, 6 glue drop tubes |

Electrical Control system | 1 |

|

Part 4 | Sandwich panel length cutting machine with cover | 1 | disc saw cutting |

Ues:

Building construction with sandwich panels has become very common in constructions. And sandwich panel development is also being advanced by a wide variety of organizations. It is only becoming difficult to adhere to the current customary use.

1.