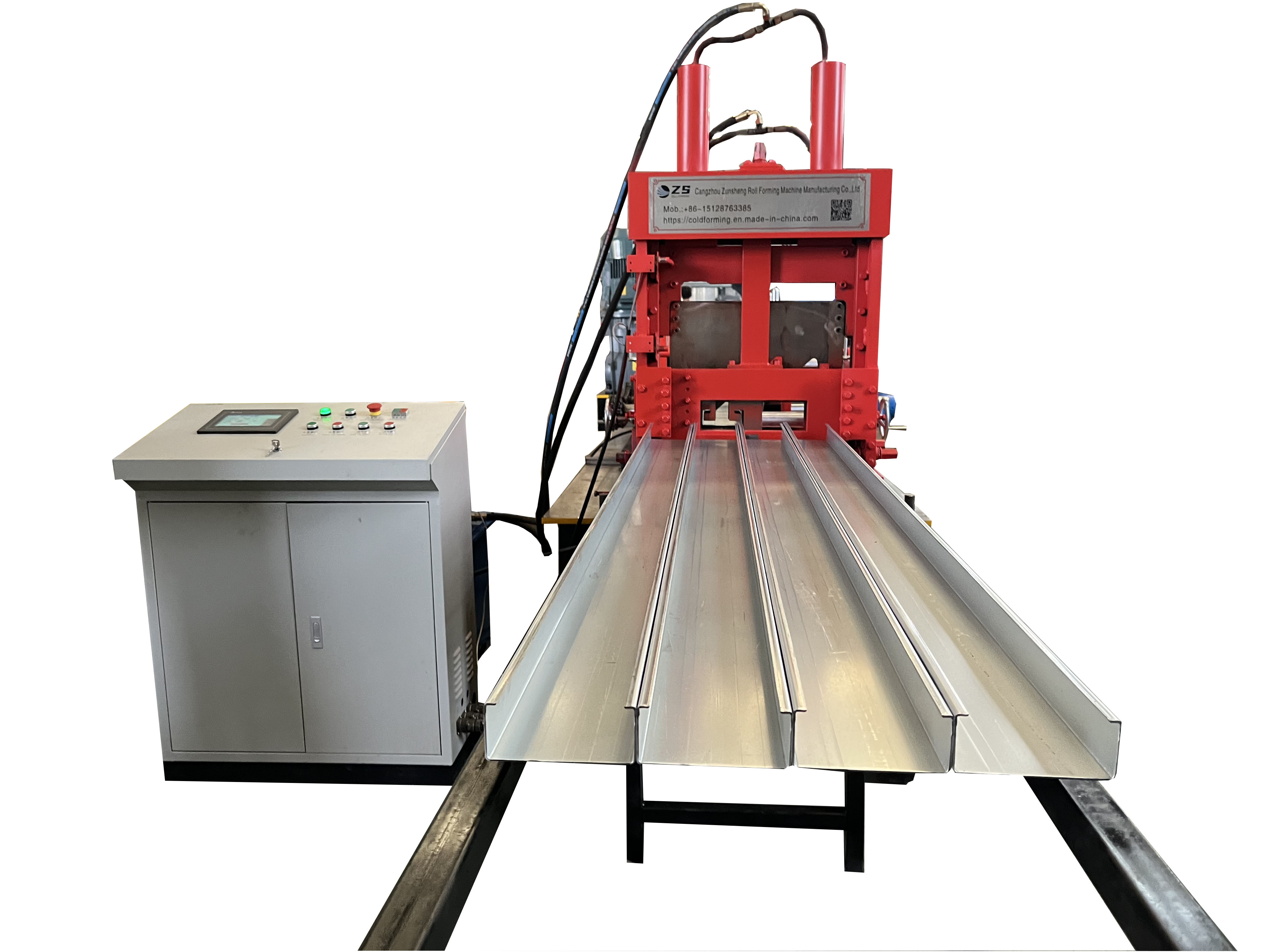

Automatic Changeable C Purlin Roll Forming Machine

C Purlin cold formed machine is adjusted sizes by fully automatic and we can set up data from PLC system.

This machine is support customize many kinds of holes for middle bottom or lip side.

Product Advantage

We use a bady casting frame for machine structure, it is does not require shearing and welding,it is can meet high precision production and make sure machine working in high strength.

2.After all the rollers and shafts are finished by CNC lathes, they are hardened and tempered, then CNC lathes are finished again, and then they are precision processed with grinders, and finally they are chrome plated.Rollers and shafts processed by these processes can be more precisely roll former gauge steel.

3. We installed a leveling system to keep galvanized coil feeder to machine and perfect roll forming.

4.We design the simple PLC system and make sure all workers can understand and operating it, it is PLC control change size.

5.We test the machine at factory and solve all issues. If customer can not arrive factory to test, we can send videos and samples by DHL to them.

6.We can provide you with a complete set of electric decoiler, inkjet printers and packing machine in one stop,and we can delivery all by one container.

Specification

No. | Item | Parameter |

|

| Material Thickness |

1.5-3.0mm |

Product Size | C Purlin Width :80-300 mm C Purlin Height : 40 - 80mm

|

2. | De-coiler Specs | Type | Manual Cantilever type |

Max. Capacity | 3Tons |

Coil ID | 508mm |

Max. Coil OD | ≤1000mm |

Max. Coil Width | ≤300mm |

3. | Machine Specs | Forming Speed | 10-15M/Min |

Forming Stations | 14 Stations |

Roller Material | GCr15,with hard treatment,HRC50-55 |

Shaft Material | Cr40,with hart treatment HRC28-32 |

Forming Structure | Guiding Column |

Base Frame | H-Section Steel Welding |

Driven System | Chain |

Motor Power | 22KW |

Change Sizes Power | 0.55KW*4=2.2KW |

Cutting Tolerance | ±2mm |

Installation Dimension | 20~25M*2M |

Machine Weight | 6 Tons |

4. | Computer Box | PLC | Delta |

Button | Emergency Stop |

5. | Paint | Base Paint | Anti-rust |

Surface Paint | Orange + Black |

6. | Others | Electric motor overloads protection |

Short circuit protection |

230V/60HZ/3Phase |

Product Uses

C-shaped steel is widely used in purlins and wall beams of steel structure buildings, and can also be assembled into lightweight roof trusses, brackets and other building components. In addition, it can also be used for columns, beams and arms in mechanical light manufacturing.

FAQ

1.Can you provide some spare parts?

Yes,the quick-wear parts will send you together with the machine.

2.Can you be responsible for transport?

Yes, please tell me the destination port or your address. we have rich experience in transportation.