Ridge Cap Roll Forming Machine

Zunsheng is ridge cap roll forming machines manufacturers and suppliers in China who can wholesale ridge cap roll forming machines. We

can provide professional service and better price for you. lf you interested in ridge cap rollforming machines products, please contact with

us. Tips: Special needs, for example: OEM, ODM, customized according to demands, design and others, please email us and tell us detail

needs. We follow the quality of rest assured that the price of conscience, dedicated service.

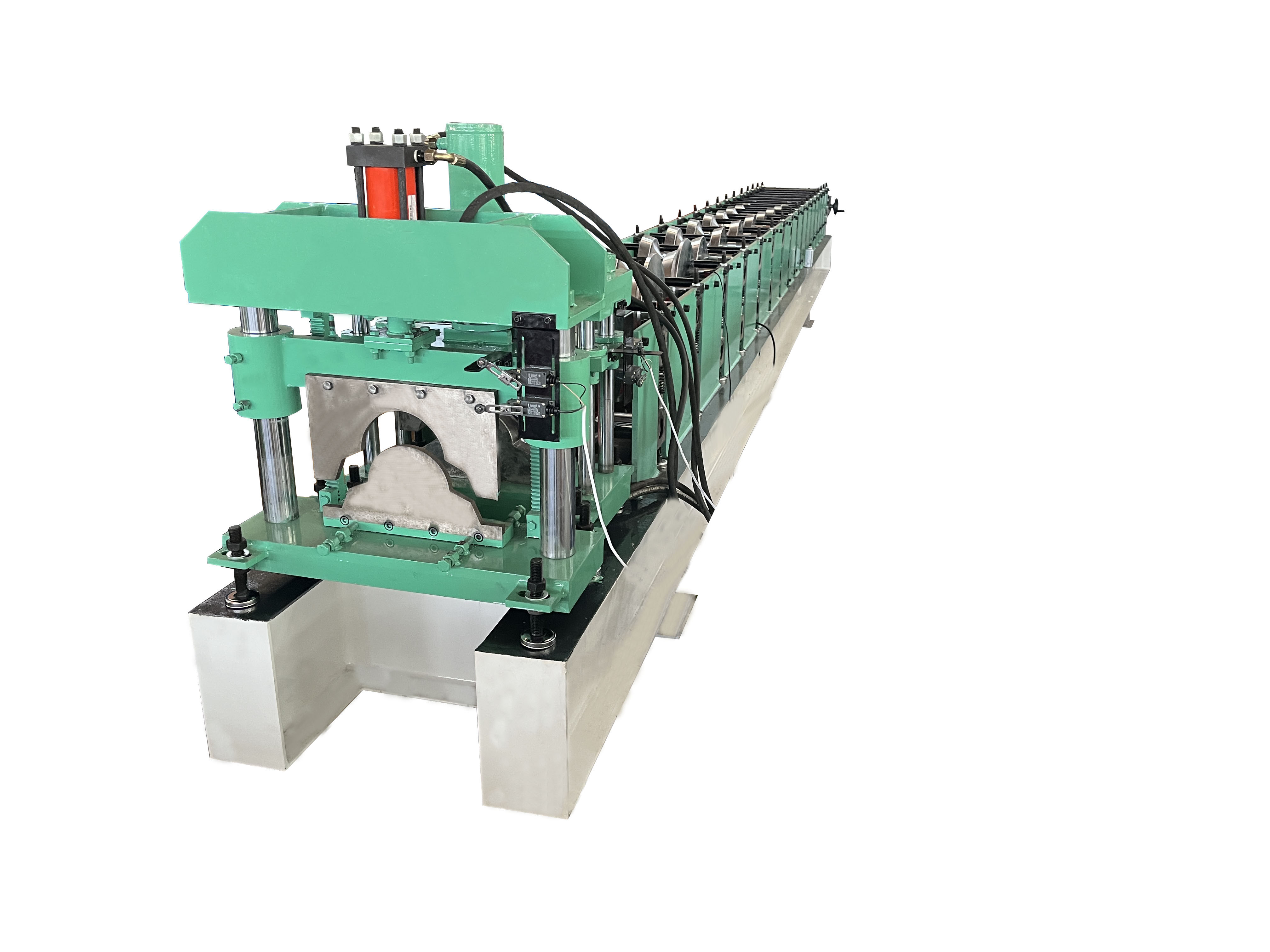

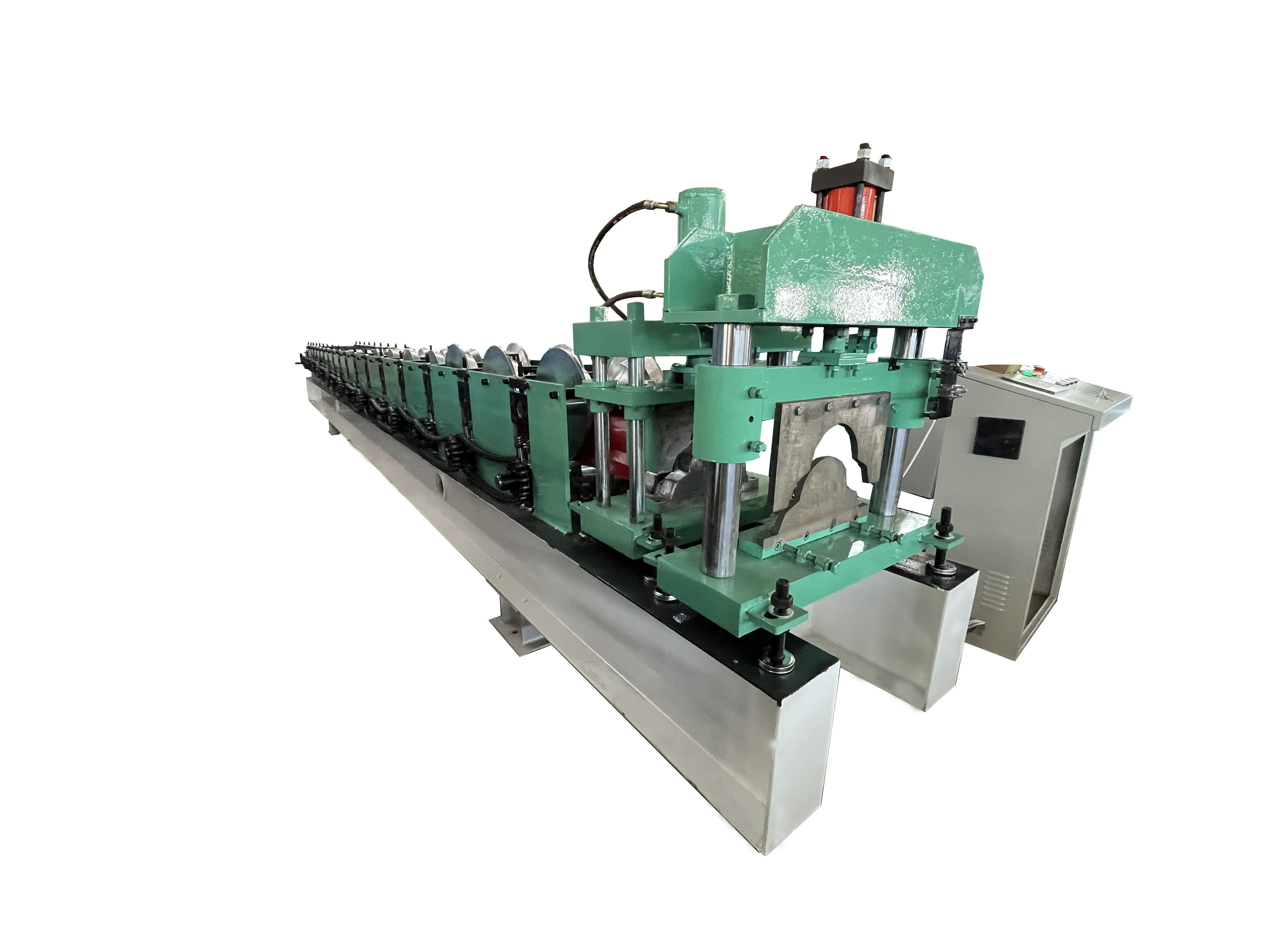

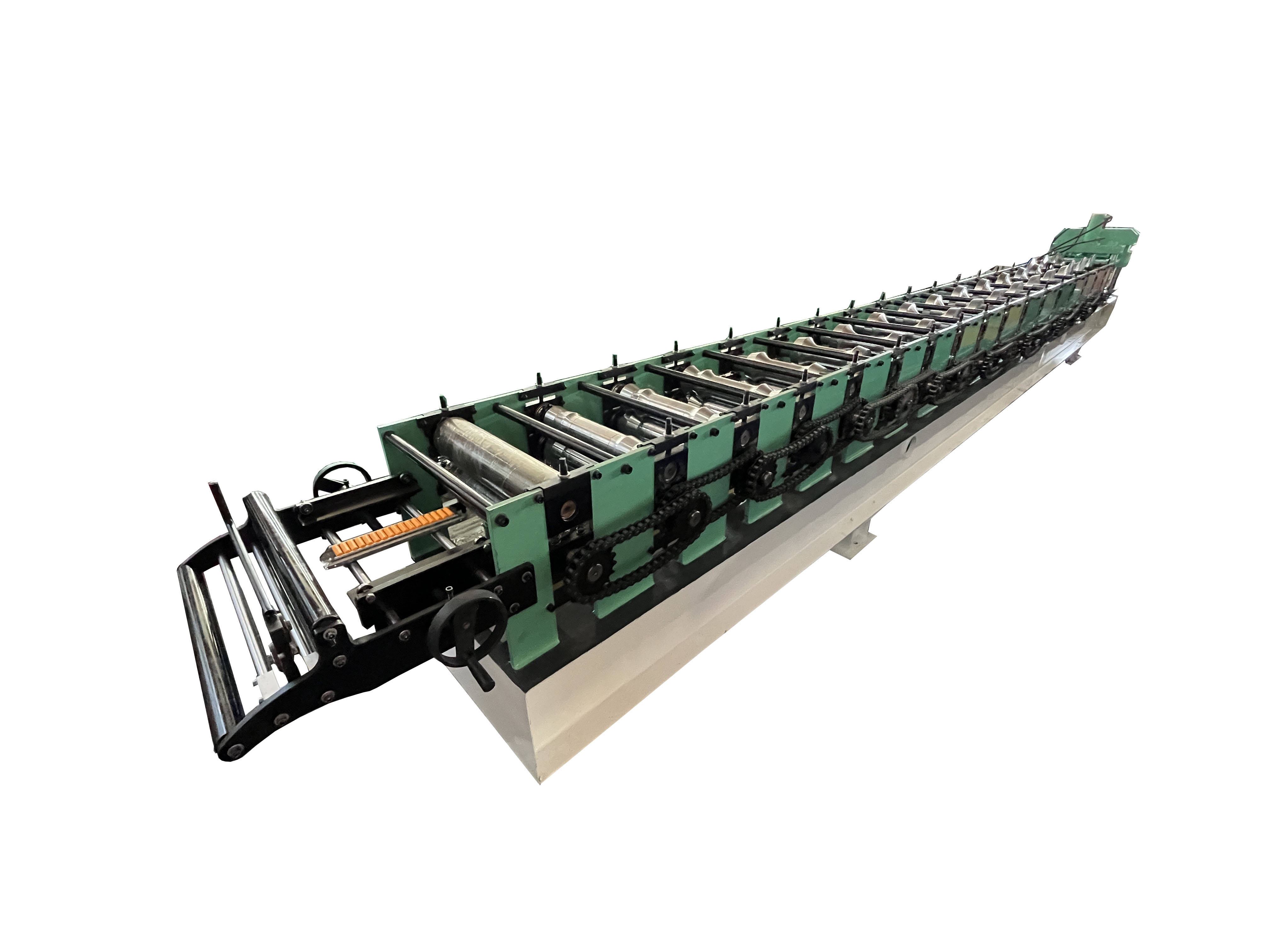

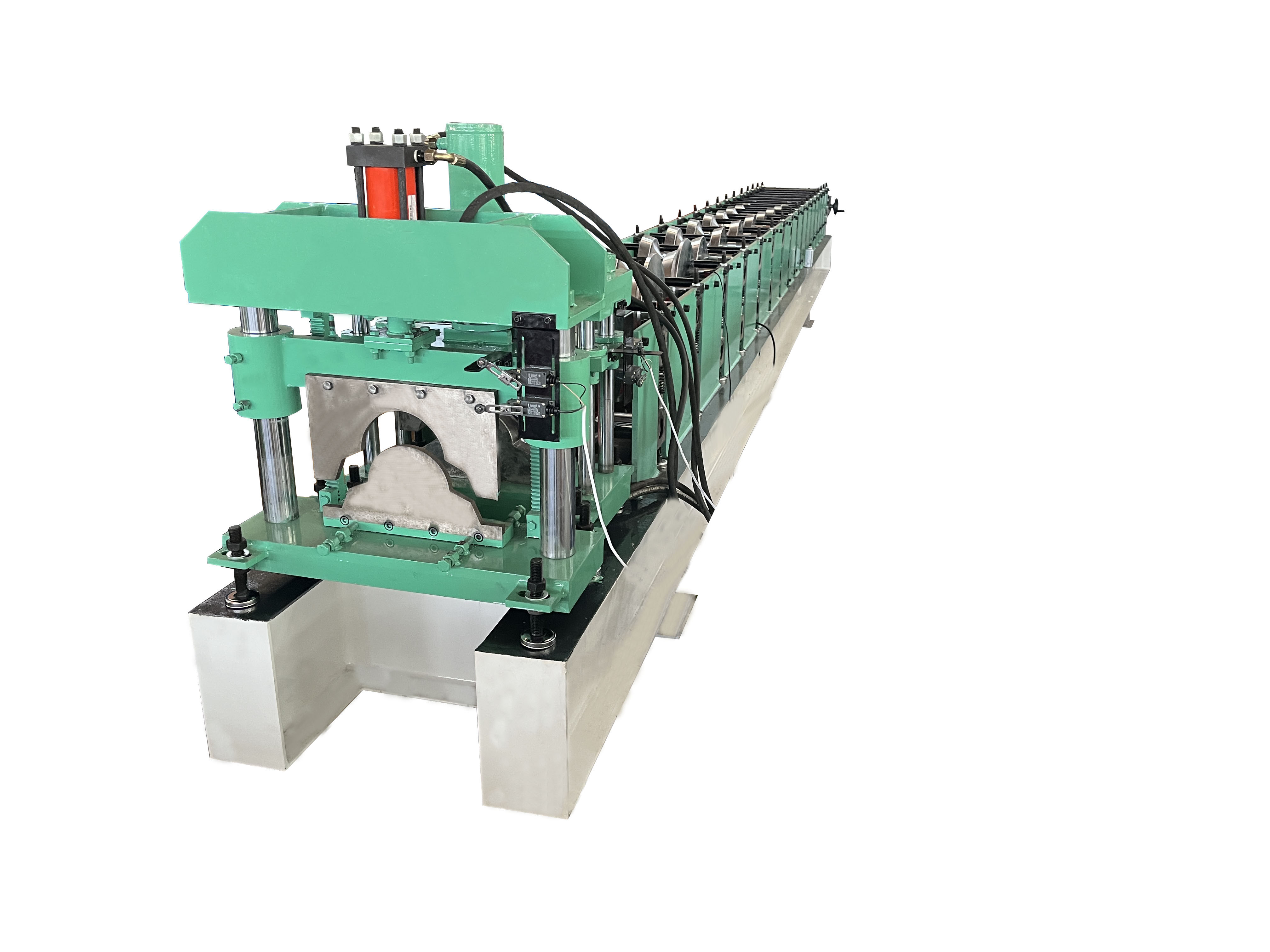

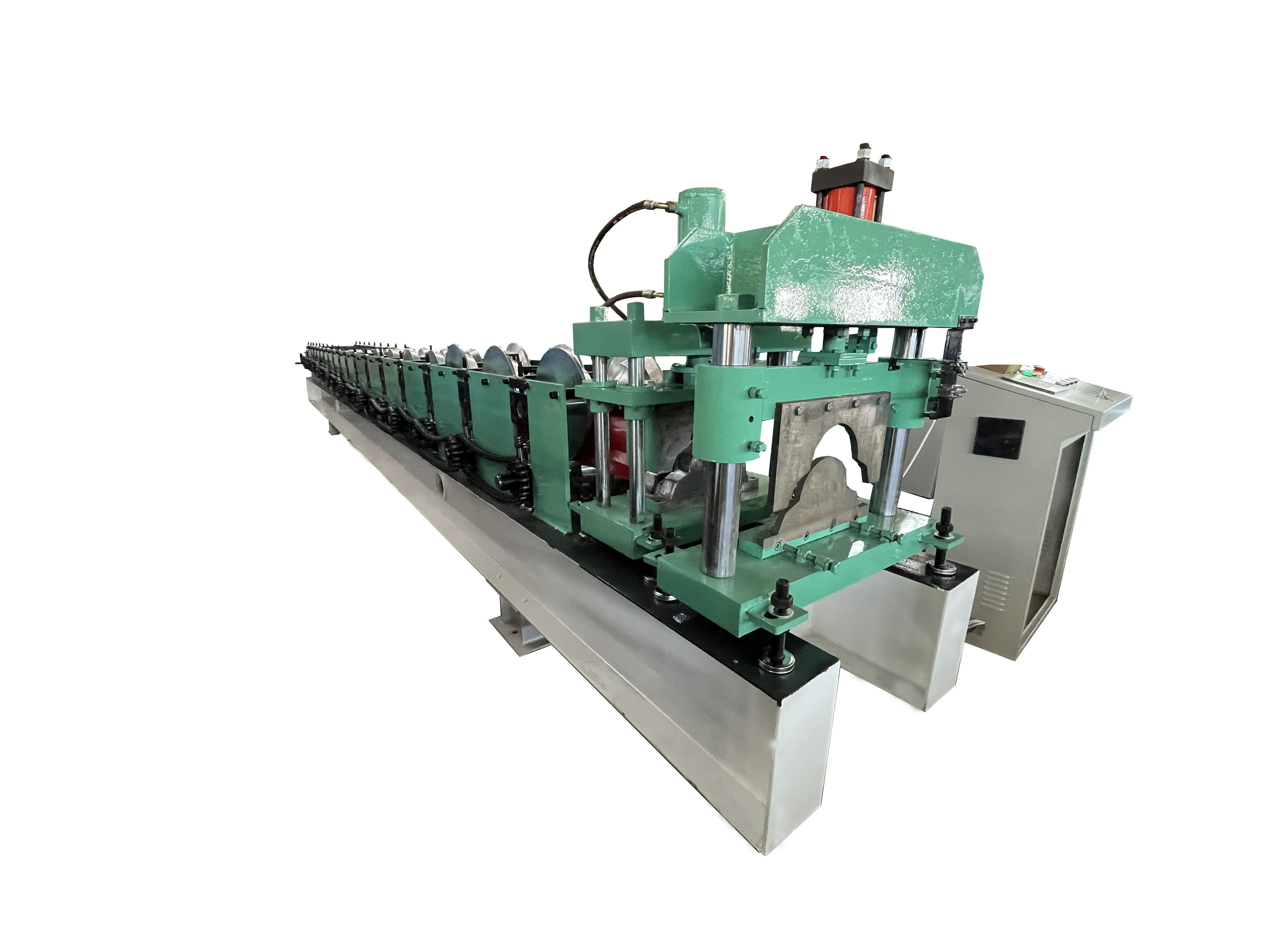

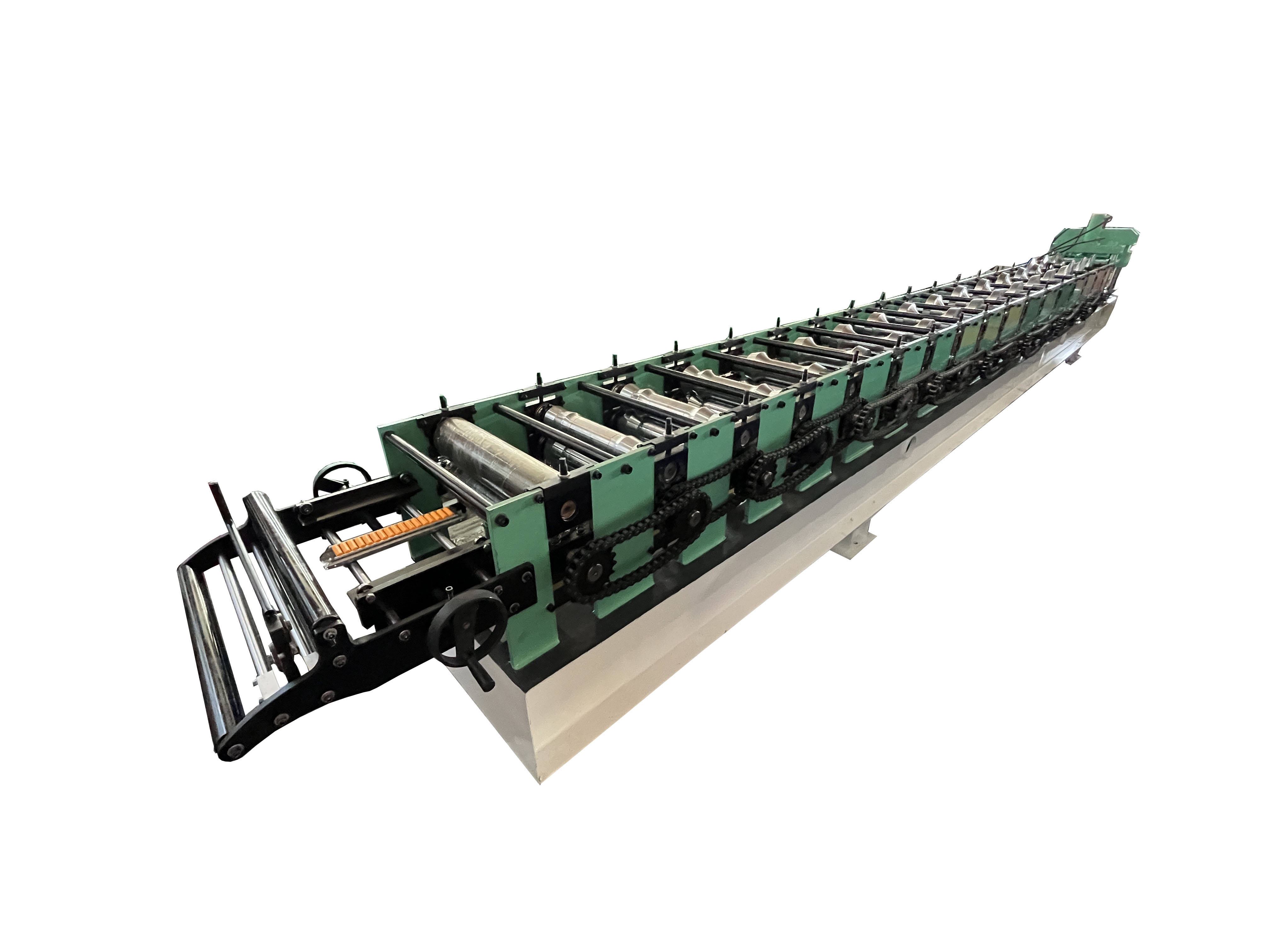

Detail Photos Of Ridge Cap Roll Forming Machine:

Specification:

| Items | Ridge Cap Roll Forming Machine |

| Total power | 4kw-5.5kw(3 phase,50 hz /60ha,380v/220v/230v/440v) |

| Speed | 0-3m/min |

| Dimension(L*W*H) | 7m*1.4m*1.6m |

| Weight | 3.0 tons |

| Roller station | 16 pairs |

| Frame | Cast frame+tube/steel box/ Steel plate+ 350H Steel |

| Material thickness | 0.3-0.6mm |

| Material width | Follow with design |

| Transmission system | Chain |

| Cutting system | Hydraulic cylinder(profile cutting system) Material SKD11 Japan |

| Control system | PLC,Xinjie/Delta |

| Runout table | Manual 3m,100kg load |

| Decoiler | Manual / Electrical,1.5 tons-7tons |

| Equipment |

| PLC | XINJIE/Delta(China) |

| Touch panel | XINJIE/Delta(China) |

| Electric motor | BOJIANG(China) |

| Encoder,relay | OMRON(Japan) |

| Hydraulic components | GUOWEI(China) |

| Cutting blades | SKD11(Japan) |

| Rollers | Cr12/GCr15/45#Steel |

Advantage:

1.Our engineer has more than 20 years experience in design rollers,so we can make sure all design roll forming in perfect.

2.All rollers and shafts processed by CNC machines,it is can keep high precesion.

3.We pay all attention to detail of machine and make all parts working well and look nice.

Use:

They are typically made of metal or shingles and are used to protect the roof cavity from water damage and to give it a finished, attractive

appearance. Ridge caps are a critical element of a roofing system and are typically installed after the roof decking, underlayment, and

flashing have been put in place.