Highway Guardrail Roll Forming Machine

Introducing our cutting-edge High-Speed Barrier Machine, designed to revolutionize the production of high-speed barriers. This state-of-the-art equipment is engineered with utmost precision and advanced technology to meet the demands of the modern construction industry.

Crafted with meticulous attention to detail, our High-Speed Barrier Machine ensures seamless and efficient production of high-speed barriers. Its robust construction guarantees durability and longevity, making it a reliable investment for your business.

Equipped with innovative features, this machine streamlines the manufacturing process, saving you valuable time and resources. Its high-speed capabilities enable rapid production, allowing you to meet tight project deadlines without compromising on quality.

The user-friendly interface of our High-Speed Barrier Machine ensures ease of operation, making it accessible for both skilled professionals and newcomers to the industry. Its intuitive controls and ergonomic design enhance productivity, minimizing operator fatigue and maximizing output.

Safety is of paramount importance, and our High-Speed Barrier Machine is built with comprehensive safety features. From emergency stop buttons to protective shields, we prioritize the well-being of your workforce, ensuring a secure working environment.

Investing in our High-Speed Barrier Machine guarantees superior quality and efficiency in the production of high-speed barriers. With its professional-grade performance and exceptional reliability, this machine is the perfect addition to your construction arsenal.

Choose our High-Speed Barrier Machine and experience the pinnacle of precision, productivity, and safety in the production of high-speed barriers. Elevate your construction projects to new heights with this cutting-edge equipment.

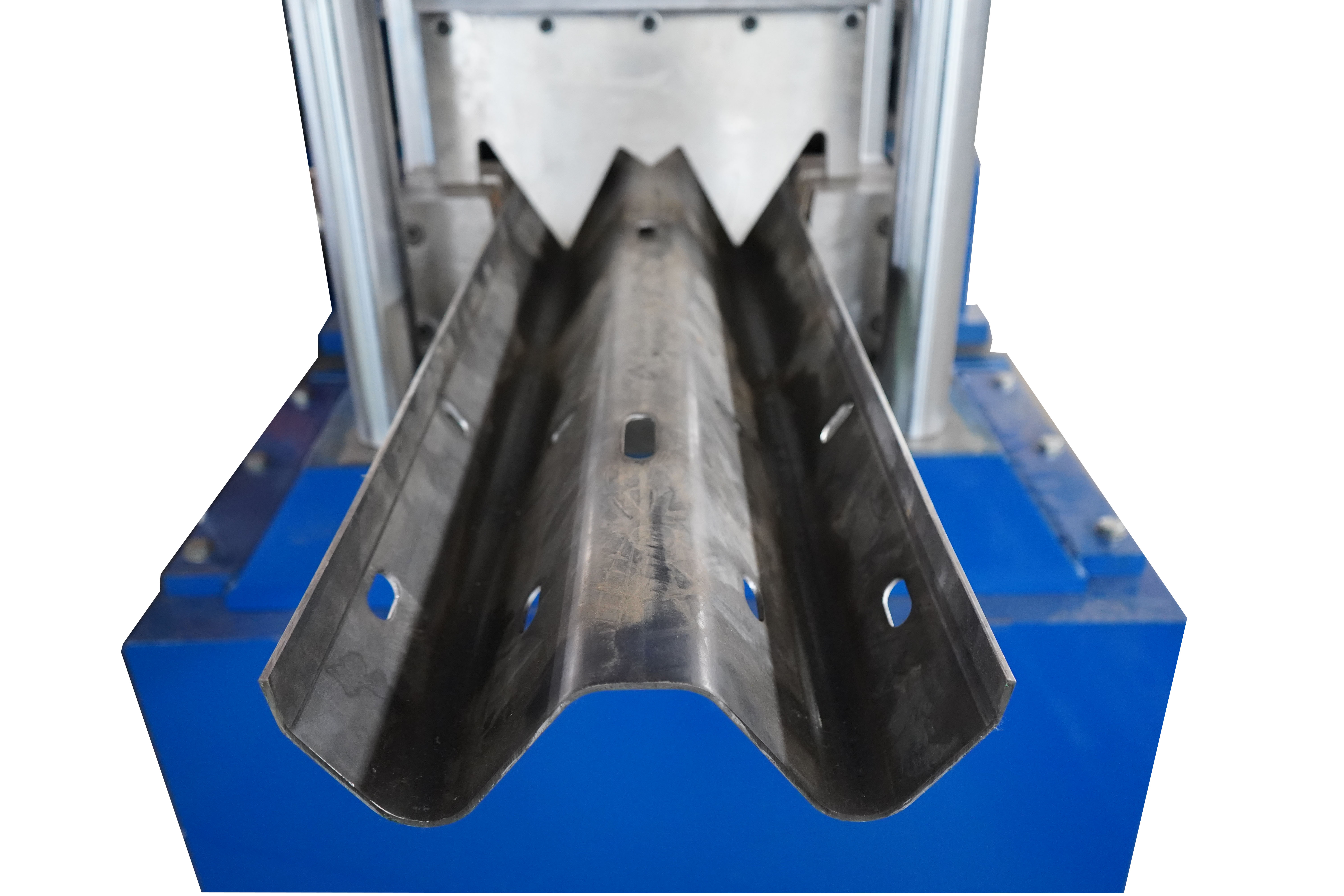

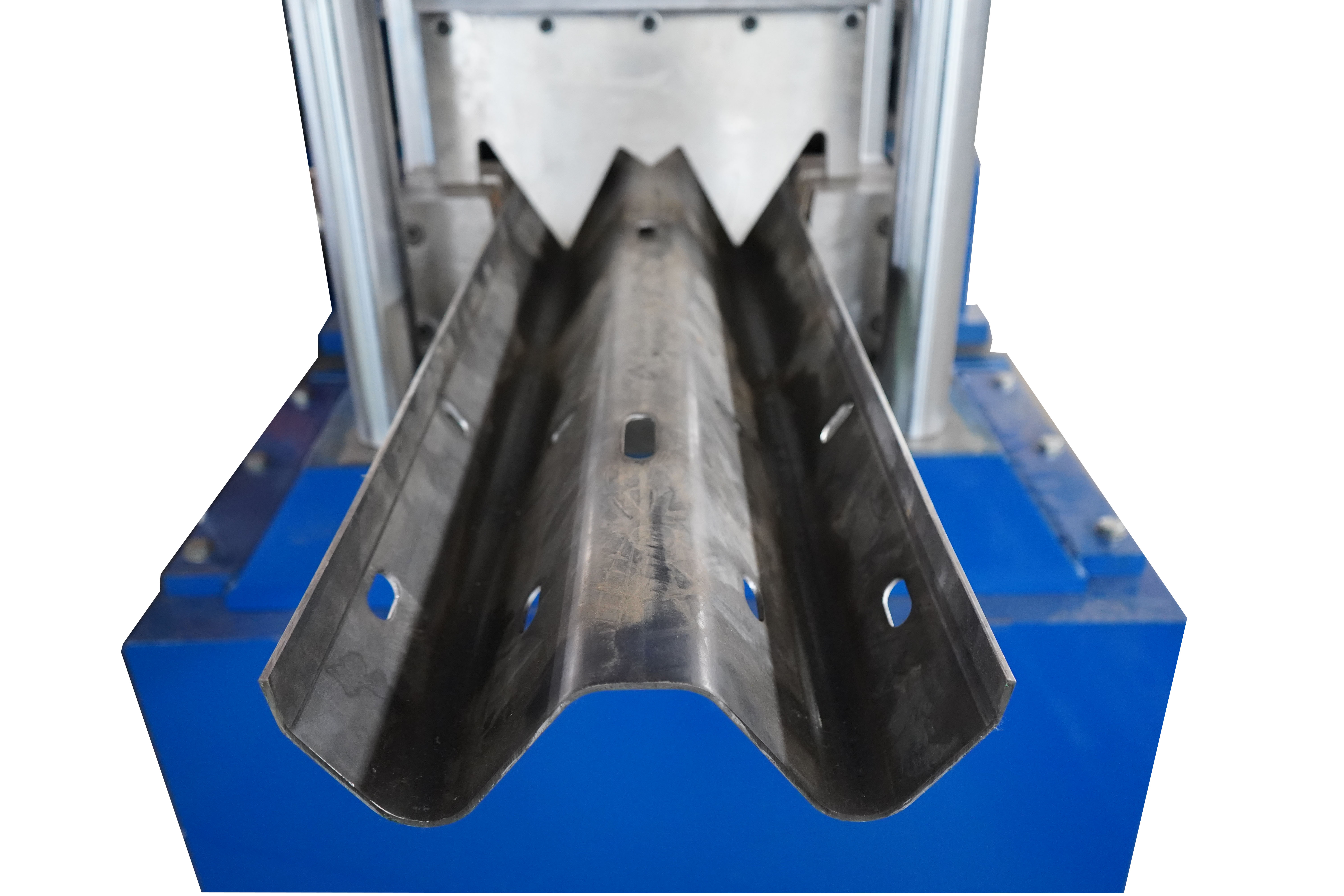

Automatic Punching System:

Heavy Duty Quality,Gearbox Transmission Roll Forming Machine:

Automatic Cutting System,stable working:

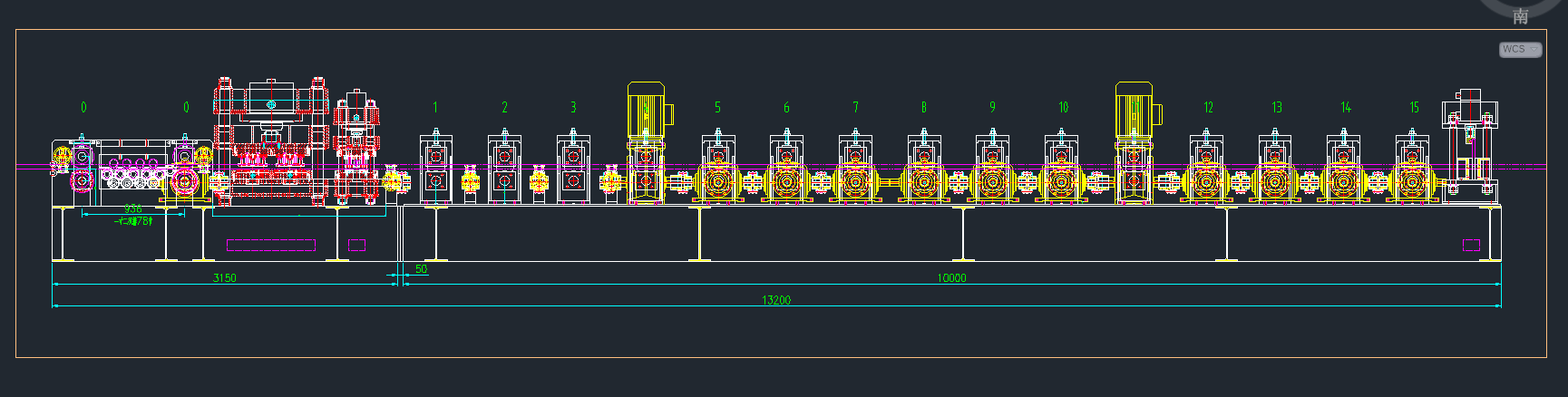

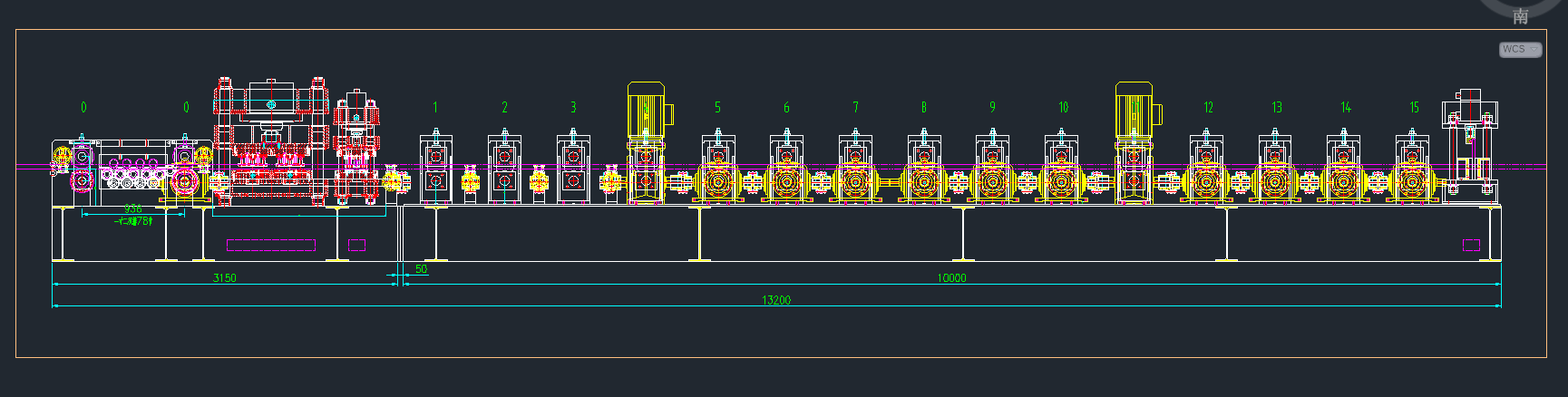

Working Flow:

Decoiler---Entry Beach&Flattening System---Punching Hole System----Roll Forming Machine----- Automatic Cutting System---Computer Control Cabinet---Run-out Tables

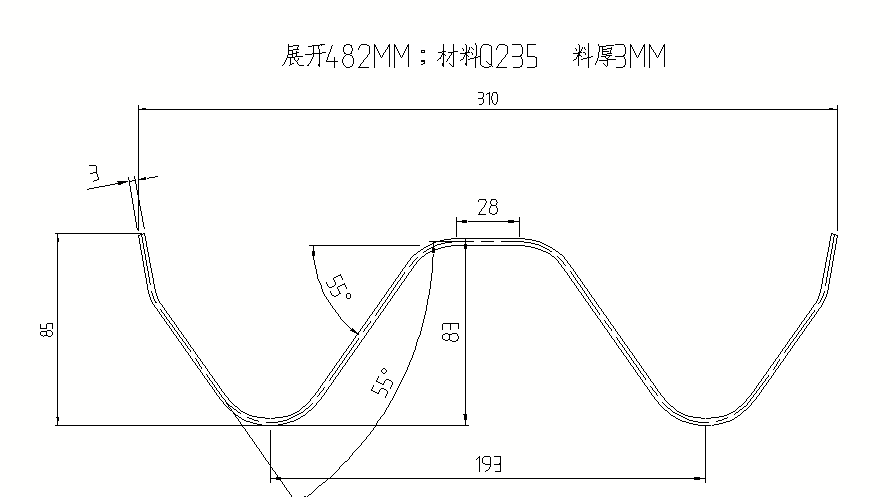

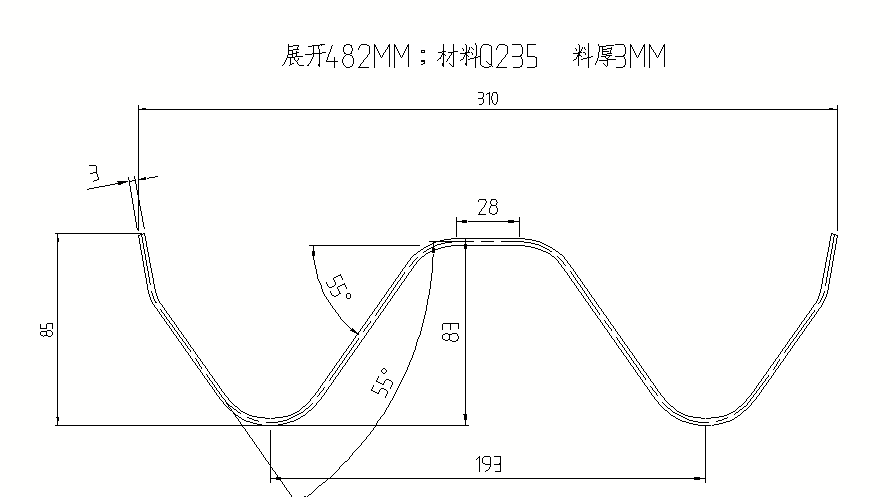

Specification Of Highway Guardrail Roll Forming Machine:

No. | Item | Unit |

|

1. | Material Of Processing |

| Galvanized steel |

2. | Thickness of steel plate | mm | Casting steel |

3. | Feed coil Thickness | mm | 3.0-4.0 |

4. | Y.S | M pa | 300 - 650 |

5. | Solid Shaft Material |

| High Grade, 45# Steel, Quenching & Tempering treatment |

6. | Shaft Diameter | mm | 110 |

7. | Roll Station | No. | 15 |

8. | Rolling material |

| GCr15 |

9. | Treatment of roller | mm | Hard chromize coated 0.05 - 0.08 |

10. | Line Speed | m/min | 8-9 |

11. | Drive Type of Roll Forming Machine |

| Gearbox |

12. | Power of Main Motor | kw | 22+22 |

Cutting Machine |

13. | Type |

| PLC controlled Hydraulic Cutting |

14. | Thickness capacity | mm | 3.0-4.0 |

15. | Width capacity | mm | As drawing |

16. | Cutting blade steel grade |

| Cr12, quenching |

17. | Hardness |

| 58-62 HRC |

18. | Cutting tolerance | mm | +/- 1 |

Control Unit |

19. | Type |

| PLC controlled |

20. | PLC brand |

| Delta |

21. | Frequency conveter |

| Delta |

22. | Frequency converter power | kw | 22 |

23. | Dimension Of Machine |

| About 16.8m*1.8m*1.7m |

24. | Weight | kgs | 22000 |

Use:

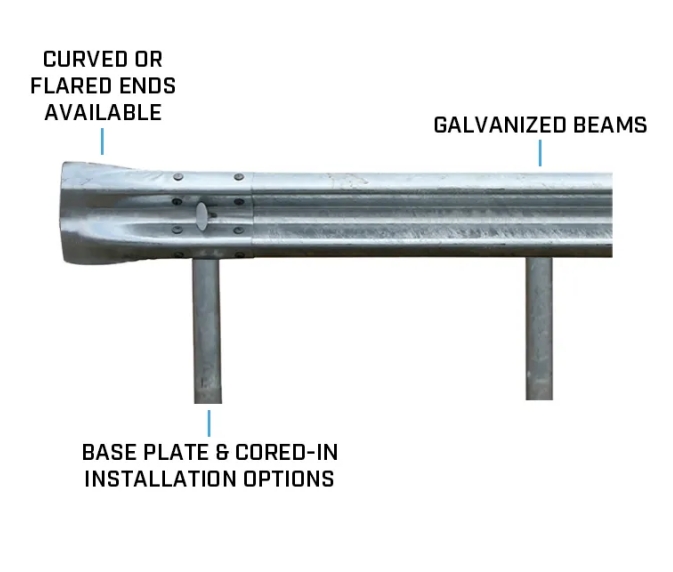

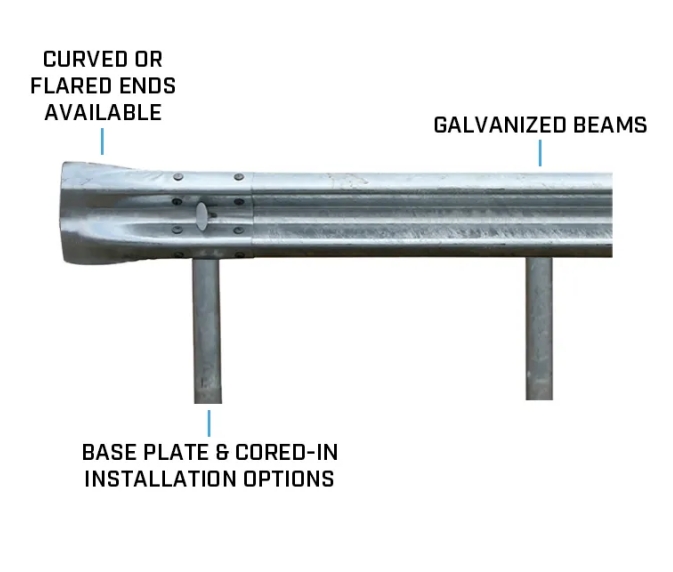

Product Application Scenarios for Highway Guardrail:

1. Urban Roads:

The Highway Guardrail finds extensive application in urban road infrastructure. It is installed along the sides of roads to provide a protective barrier between vehicles and pedestrians, ensuring their safety. The guardrail effectively prevents vehicles from veering off the road and minimizes the risk of accidents. Its sturdy construction and easy installation make it an ideal choice for urban roads, enhancing the overall safety of the transportation network.

2. Highways and Expressways:

Highways and expressways witness high-speed traffic, making them prone to accidents. The Highway Guardrail is specifically designed to withstand the impact of high-speed collisions, thereby reducing the severity of accidents. Its robust structure and secure installation provide a reliable safety barrier, preventing vehicles from crossing over into opposing traffic lanes. The ease of installation ensures quick deployment along vast stretches of highways and expressways, enhancing road safety for motorists.

3. Mountainous Terrain:

In mountainous regions, roads often traverse challenging landscapes with steep slopes and sharp curves. The Highway Guardrail is indispensable in such scenarios as it offers crucial protection against vehicles losing control and plummeting down slopes. By providing a secure barrier, it prevents accidents caused by vehicles veering off the road due to challenging terrain. The guardrail's easy installation facilitates its implementation even in remote mountainous areas, ensuring the safety of motorists navigating through difficult terrains.

4. Bridges and Overpasses:

Bridges and overpasses are critical components of transportation infrastructure, requiring additional safety measures. The Highway Guardrail is extensively used on bridges and overpasses to prevent vehicles from colliding with the bridge structure or falling off the elevated roadway. Its strong and durable construction ensures the guardrail can withstand the impact of accidents, minimizing damage to the bridge and ensuring the safety of motorists. The ease of installation enables efficient deployment on various bridge designs, enhancing overall bridge safety.

5. Construction Zones:

During road construction or maintenance activities, temporary traffic diversions and detours are common. The Highway Guardrail serves as a temporary safety barrier in construction zones, guiding traffic and protecting workers and motorists. Its easy installation and removal make it an ideal solution for temporary applications. The guardrail effectively separates the construction area from the traffic flow, preventing accidents and ensuring the safety of both workers and passing vehicles.

6. Industrial Areas:

Industrial areas often witness heavy vehicle movement, including trucks and forklifts. The Highway Guardrail is employed in industrial zones to create safe traffic routes, segregating pedestrian areas from vehicular pathways. By providing a physical barrier, it prevents accidental collisions and ensures the safety of workers and pedestrians. The guardrail's sturdy construction withstands impacts from heavy vehicles, maintaining a secure environment within industrial premises.

In summary, the Highway Guardrail is a versatile product with multiple application scenarios. Its robust construction, easy installation, and ability to withstand high-speed impacts make it an essential safety measure for urban roads, highways, mountainous terrains, bridges, construction zones, and industrial areas. By providing a secure barrier, it enhances road safety, prevents accidents, and protects both motorists and pedestrians.