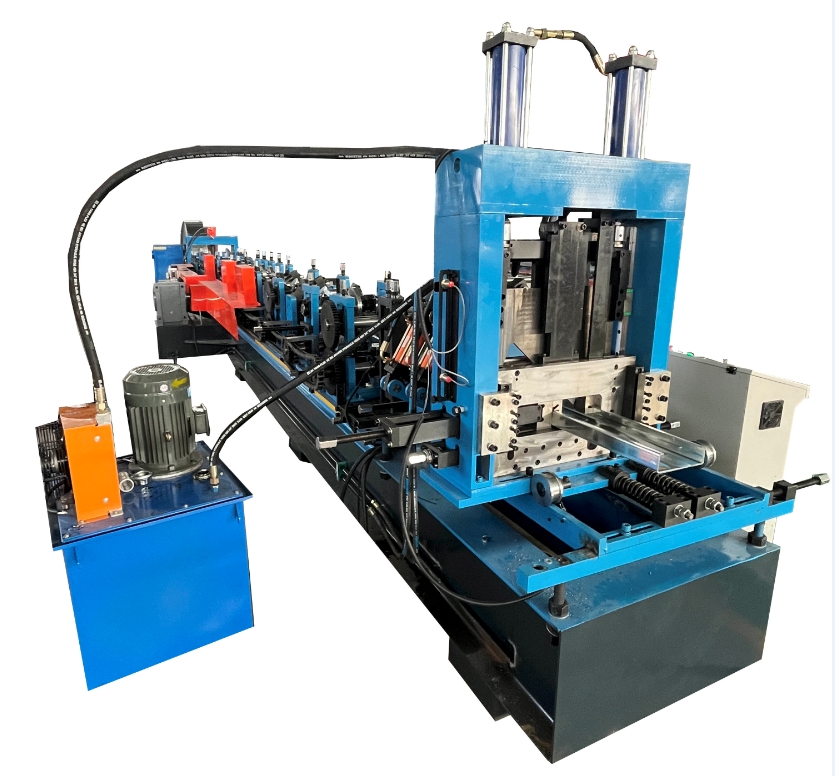

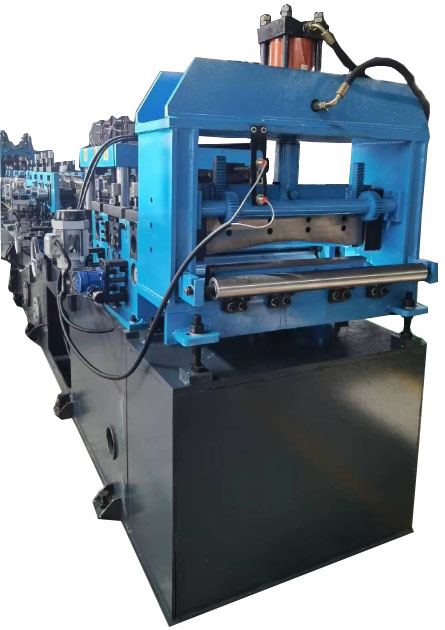

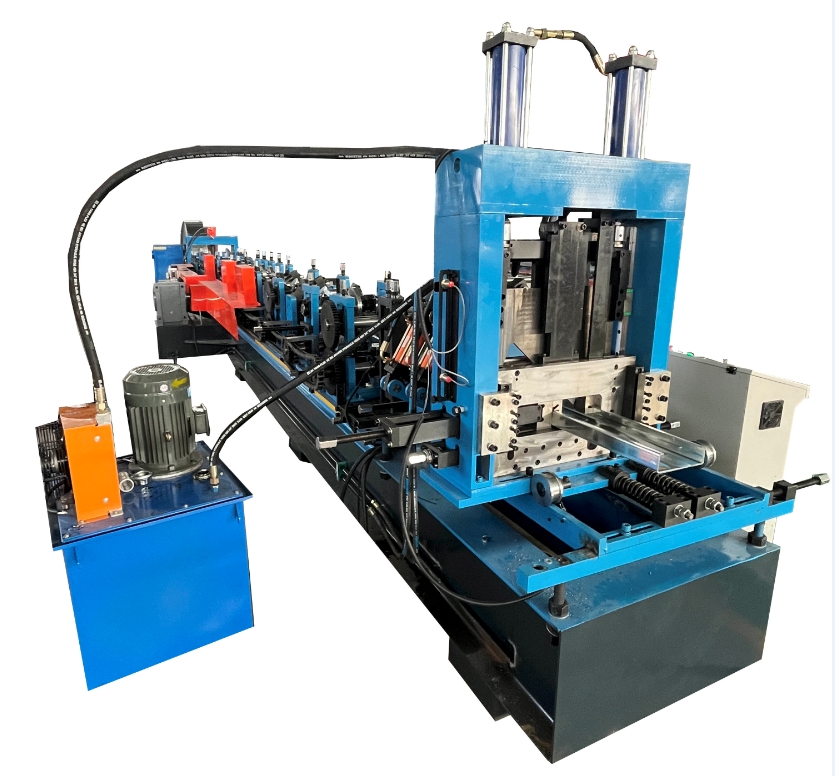

Automatic Interchangeable Peb Steel Construction Metal Frame C Z Purlin Roll Forming Machine

The fully automatic C/Z steel integrated machine is also called the C/Z interchange molding machine, and C and Z interchange purlin machine. The fully automatic CZ purlin machine provides users with highly automated purlin forming equipment that can realize the interchange production of C/Z two models and various specifications purlins in a short time by PLC computer control.

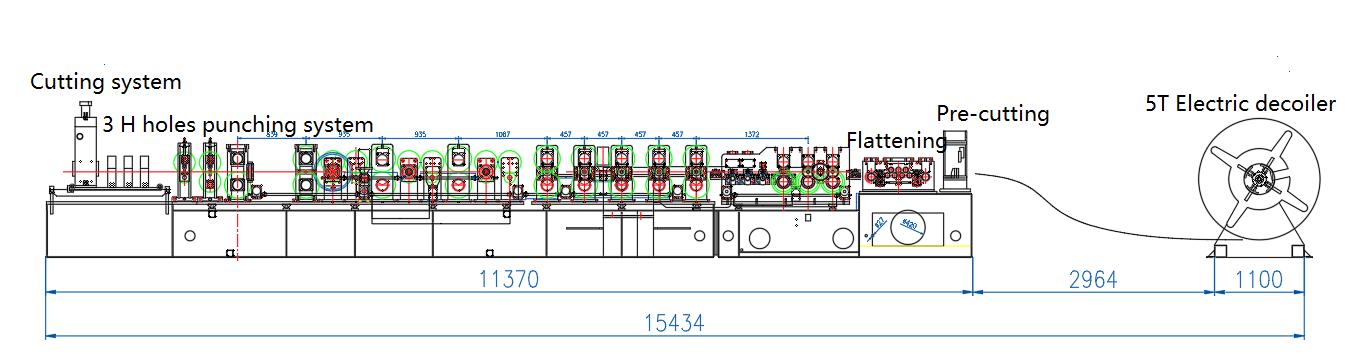

Featuring a 7-unit automatic change system, this roll forming machine is equipped with pre-cutting, leveling, pre-punching, post-punching, and adjustable cutting functions. This comprehensive range of features allows for seamless production and eliminates the need for manual adjustments, saving you time and effort.

The Zunsheng Automatic Adjustable C Z Purlin Roll Forming Machine is designed to handle a wide range of specifications. It can produce purlins with a height ranging from 40mm to 80mm, a width ranging from 80mm to 300mm, and a thickness of 2mm to 3mm. This versatility ensures that you can meet the specific requirements of your projects with ease.

With the Zunsheng brand name, you can trust in the quality and reliability of this roll forming machine. We are committed to providing top-notch products that deliver exceptional performance and durability.

:

We use 10mm steel plate welding bottom structure,30mm steel plate for bottom table,CNC Machine processing surface.

Seamless C/Z Purlin Conversion

Automatic switching between C and Z profiles without changing rollers, reducing downtime.

Advanced PLC Control System

Intuitive interface for precise operation and real-time adjustments, ensuring production accuracy.

Robust Material Compatibility

Suitable for processing a variety of materials including galvanized steel, cold-rolled steel, and stainless steel.

Customizable Design

Supports various purlin widths (80-350mm) and thicknesses (1.5-3.5mm), catering to diverse structural needs.

High Production Efficiency

Operates at speeds of 8-15 meters per minute with automated punching and cutting processes.

Durability & Stability

Built with high-grade steel frames and reinforced components for long-term reliability.

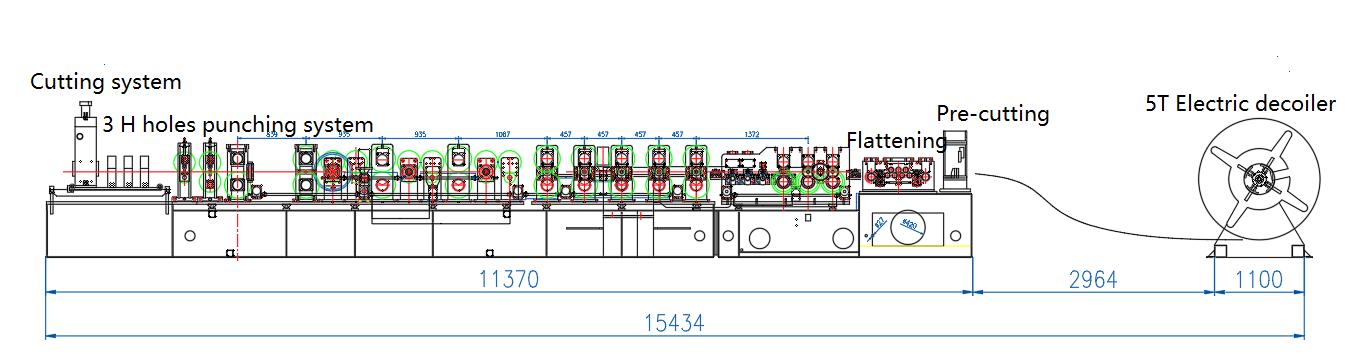

We add pre-cutting,when order is finish,it is automatic cutting coil,then it is can save material:

Working Flow:

Electric decoiler----Pre-cutting system---Flattening System---Roll Forming Machine----Punching Hole system----Automatic Cutting Machine-----Computer Control System-----Product Receive Table

Specification:

No. | Item | Parameter |

1. |

| Material Thickness |

1.5-3.0mm |

Product Size | Width :75-300 mm Height : 40 - 100mm |

2. | De-coiler Specs | Type | Electric Cantilever type |

Max. Capacity | 5Tons |

Coil ID | 480-520mm |

Max. Coil OD | ≤1000mm |

Max. Coil Width | ≤300mm |

3. | Flattening system | Thickness of frame | 30mm |

Diameter of shaft | 80mm |

Shaft No. | Down 4+Up 3 |

Material of shaft | 45#steel,with hard treatment HRC56 and chrome coating |

Diameter of feeder Coil shaft | 100mm |

Feeder coil shaft No. | 2 |

Material of feeder coil shaft | 45#steel,with hard treatment HRC56 and chrome coating |

4. | Machine Specs | Forming Speed | 10-25m/min |

Forming Stations | 18 Stations |

Roller Material | Main rollers use GCr15,Auxiliary side roller use Cr12,with hard treatment HRC58-60 and chrome coating. |

Shaft Material | 45#steel,with hard treatment HB210-230 and chrome coating |

Diameter of shaft | Main shaft is 90mm, change size shaft is 75mm |

Forming Structure | Guiding Column |

Base Frame | Steel Welding |

Driven System | Chain,2 inches and 1.5 inches |

Motor Power | 37KW Servo Motor,Zhongchen Brand,with K107 Reducer,Shanghai Bojiang Brand. |

Change Sizes Power | 0.37KW*2,0.55KW*2,1.1KW*1,0.75KW*2 |

Cutting Tolerance | ±2mm |

Installation Dimension | 20~25M*2M |

Machine Weight | 15 Tons |

5. | Computer Box | PLC | Weikong |

Button | Emergency Stop |

6. | Hydraulic | Power of hydraulic | 11KW |

Cooling system | Fan |

Capacity of box | 300L |

7. | Paint | Base Paint | Anti-rust |

Surface Paint | Blue + Black |

8. | Others | Electric motor overloads protection |

Short circuit protection |

380V/50HZ/3Phase |

Use of C Z Purlin:

A purlin is a horizontal beam or bar that gives structural support for buildings, typically beneath the roof. The rafters of the building or its walls support the purlins. Although they are most frequently used in metal buildings, these can also replace densely packed rafters in wood-frame buildings. The purlins of a roof sustain the weight of the roof deck. The hardwood panel, plyboard, or sheet metal that forms the roof surface is known as the roof deck. This is often made of concrete, filled with some sort of weatherproofing, and commonly covered in insulation.

Q1: Can the machine handle custom purlin sizes?

Yes, the machine is highly adaptable and can be tailored to produce non-standard sizes upon request.

Q2: How long is the warranty?

We offer a 1-year warranty with lifetime technical support.